Multi-position self-aligning system with track movable type belt discharging trolley and control method thereof

A technology of unloading trolley and automatic alignment, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of poor stability of reflective sensors, incorrect alignment, high cost, etc., and achieves fewer components, easy maintenance, and The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

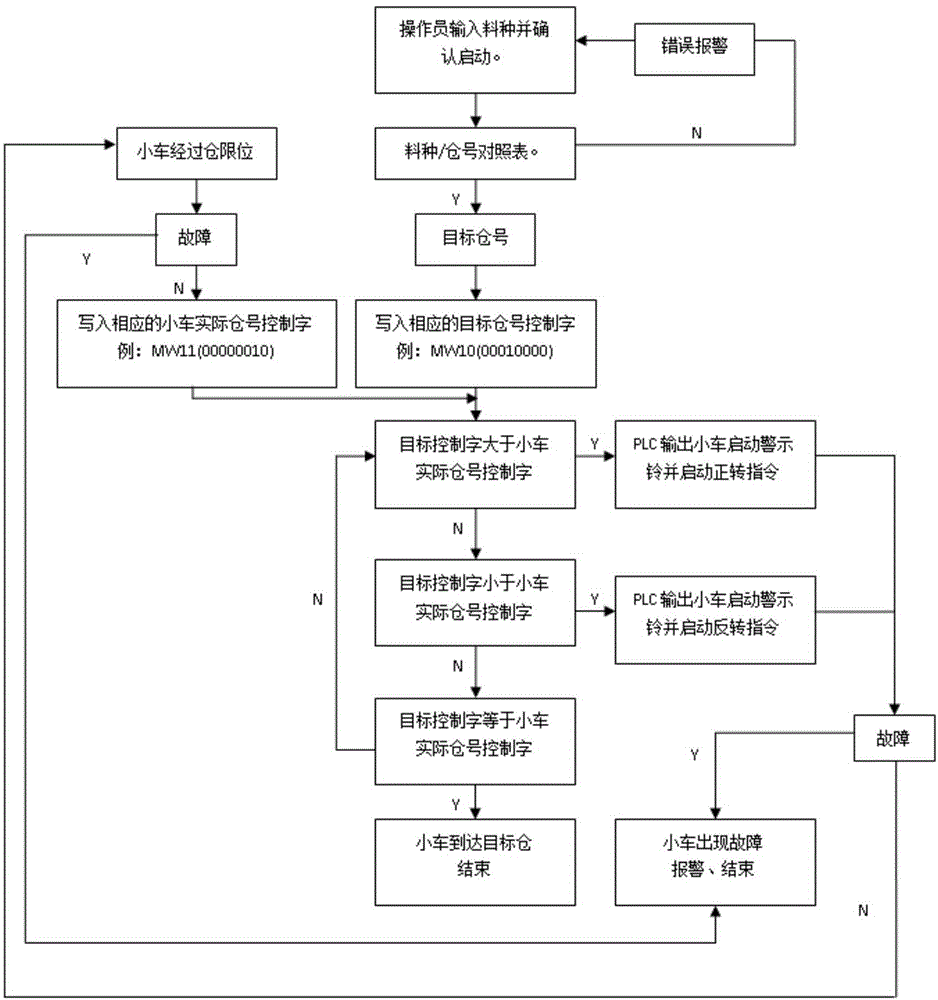

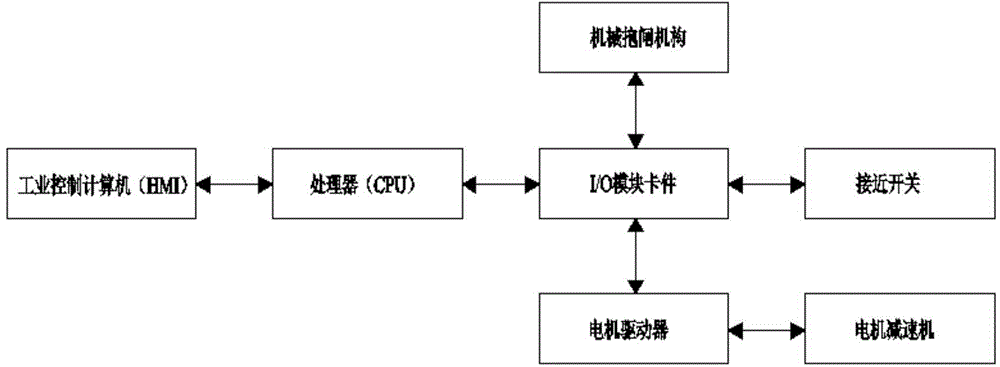

[0034] combined with Figure 4 , a track-moving belt unloading trolley multi-point automatic alignment system of the present invention, including a positioning structure and an electrical control system:

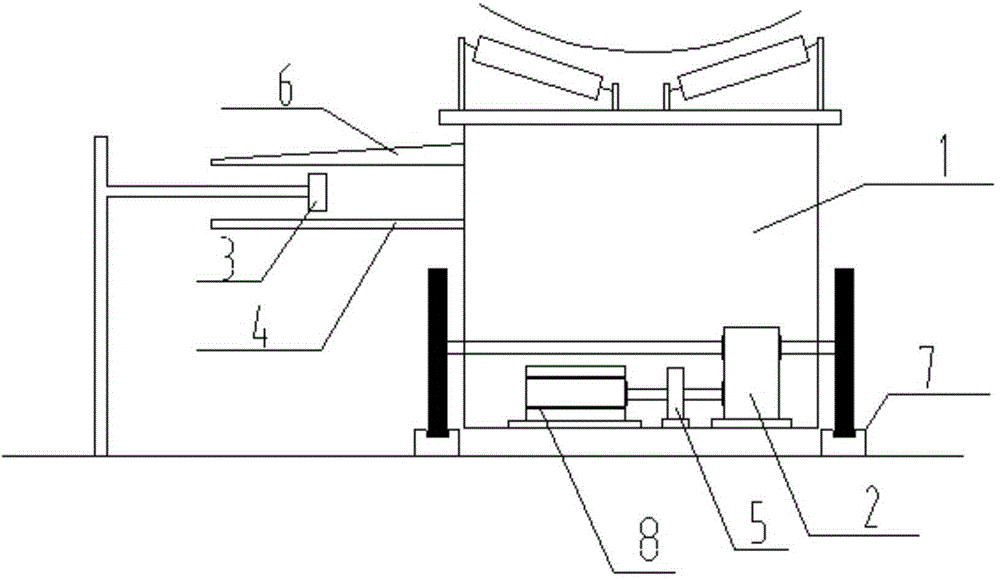

[0035] combined with image 3 , The positioning structure includes a mobile unloading trolley 1, a motor reducer 2, a proximity switch 3, a touch iron 4, a mechanical brake mechanism 5, a trolley track 7, a traveling motor 8 and a dust cover 6. The mobile unloading trolley 1 is installed on the trolley track 7, the touch iron 4 and the dust cover 6 are arranged on the same side of the mobile unloading trolley 1, and a proximity switch 3 is also provided on the same side of the ground , the indicators of the selected proximity switch 3 are as follows: U: 220VAC, I: 400mA, Sn: 20mm, the installation position of the proximity switch 3 is located at the vertical center point of each target bin in the vertical direction, and the dust cover 6 is arranged directly above the proxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com