Canal engineering system and construction method

A water channel and engineering technology, applied in water conservancy projects, artificial water channels, manufacturing tools, etc., can solve problems such as wasting labor and working time, affecting the service life of beams and grooves, and extrusion and deformation of water channels and grooves, and achieves convenient removal and shortens construction. Construction period and good sealing effect of butt joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention is further described in detail in conjunction with the embodiments of the present invention.

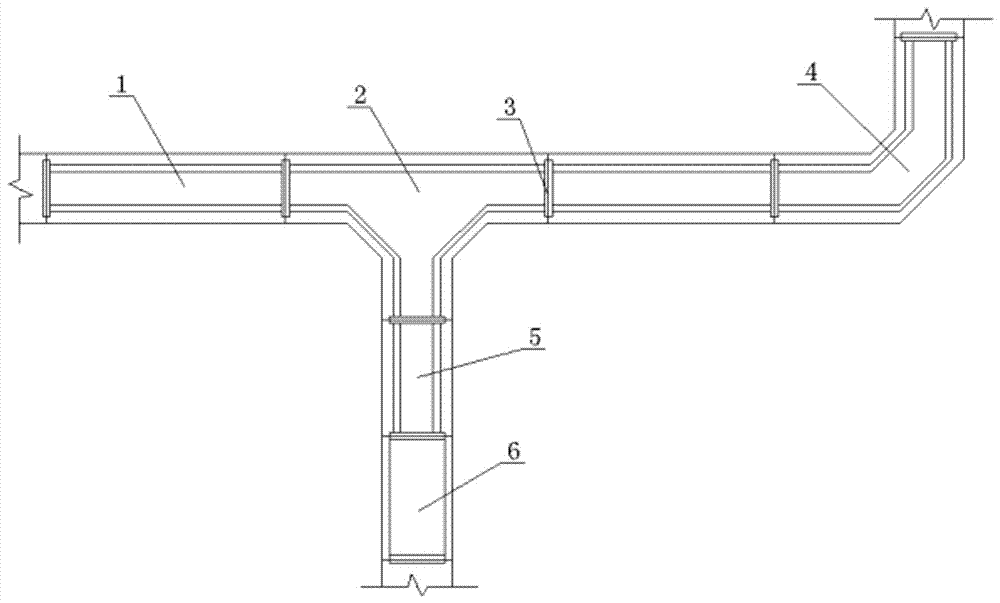

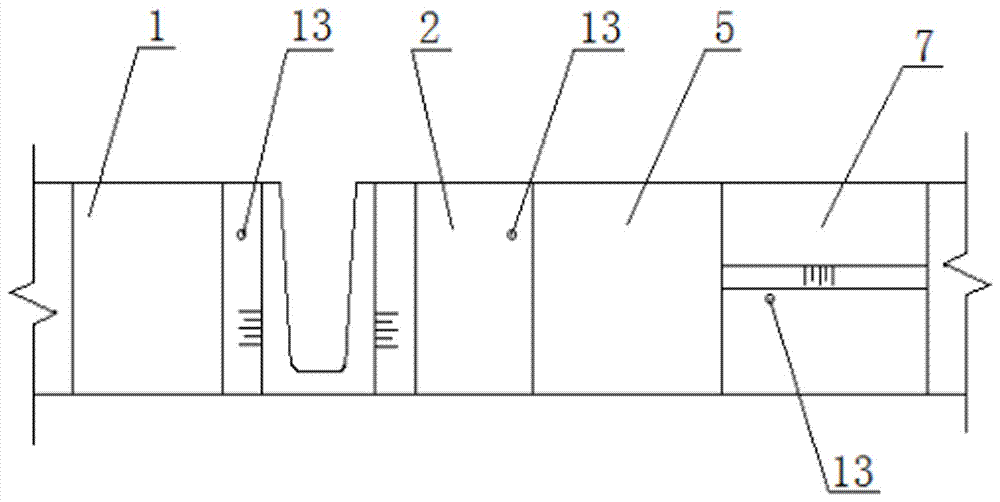

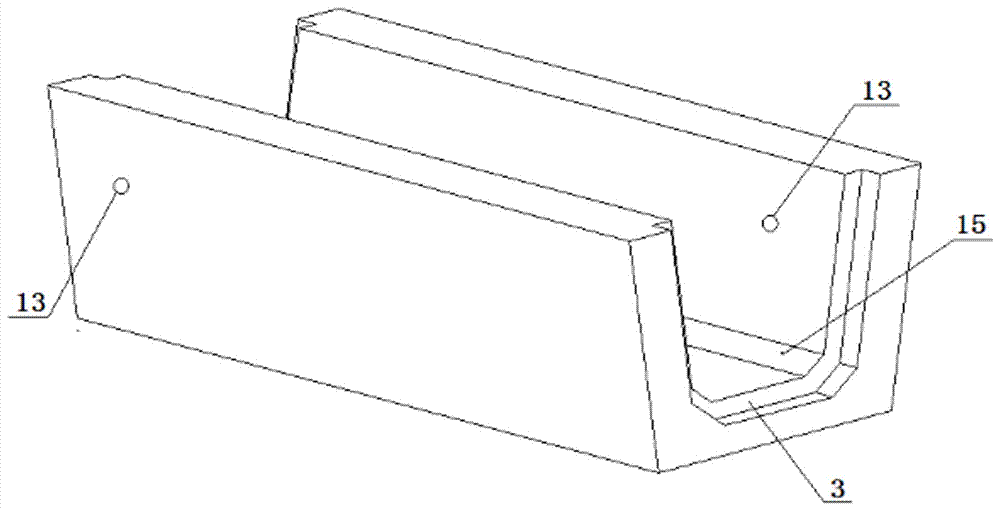

[0060] see Figure 1-11 As shown, a water channel engineering system and construction method, the water channel engineering system includes a water channel channel prefabricated part 1, a water channel tee prefabricated part 2, a docking groove 3, a water channel corner prefabricated part 4, a water channel side pass prefabricated part 5, Aqueduct crossing prefabricated part 7 and aqueduct cover plate prefabricated part 6; said aqueduct channel prefabricated part 1, tee prefabricated part 2, aqueduct corner prefabricated part 4, aqueduct side passage prefabricated part 5, aqueduct passing prefabricated part 7 and aqueduct cover The slab prefabricated parts 6 are connected according to the requirements of the canal system to form a canal engineering system; the canal crossing prefabricated part 7 must cooperate with the canal cover plate prefabricated part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com