Stand column type capsule tire vulcanizer

A tire vulcanization, column-type technology, applied in the field of column-type bladder tire vulcanizers, can solve the problems of high labor intensity, poor product quality, low production efficiency, etc., to improve stability and safety, reduce labor intensity, The effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

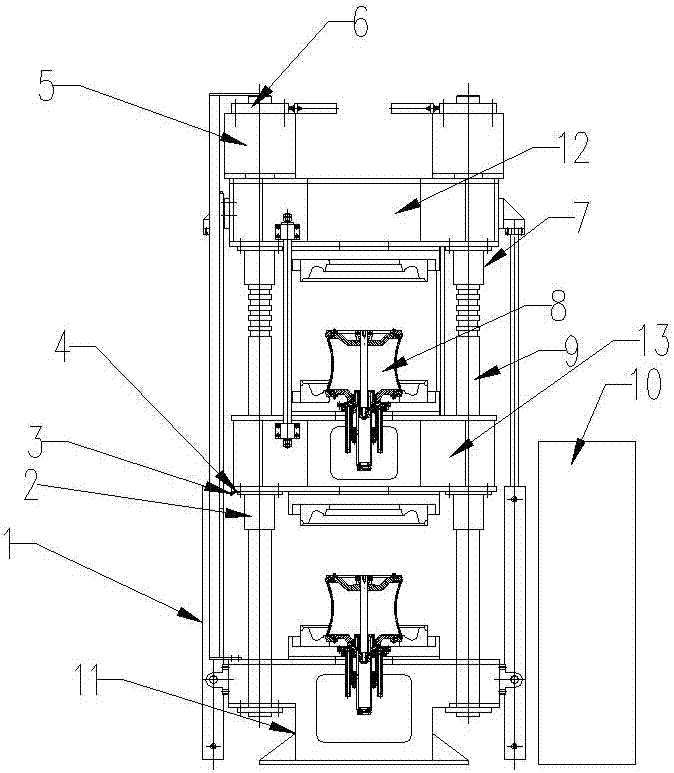

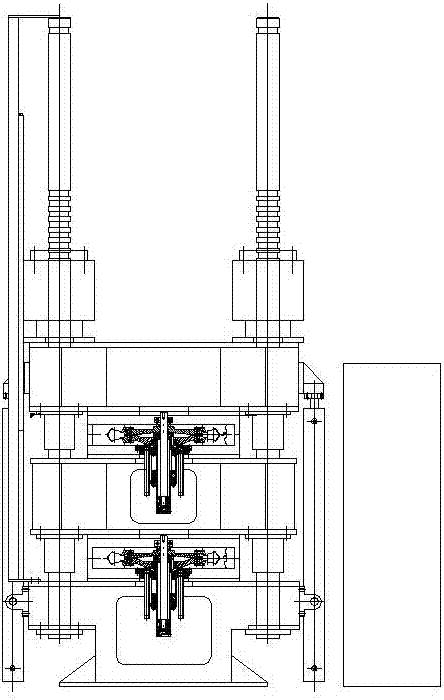

[0022] See Figure 1-2 In the embodiment of the present invention, a column type capsule tire vulcanizer includes a quick cylinder mold opening and closing mechanism, an afterburner cylinder mechanism 5, a pneumatic locking device 6, a self-lubricating sliding bearing 7, a capsule center mechanism 8, and a column The sliding frame guide mechanism 9, the electrical cabinet 10 and the base 11; the quick-cylinder mold opening and closing mechanism includes a driving device 1, a guide device 2, a limit device 3, and a stroke adjusting device 4. The column sliding frame guide mechanism 9 is located on the base respectively The left and right ends of 11 are fixed on the base 11. The capsule center mechanism 8 is installed on the center of the base 11, and the guide device 2 is sleeved on the column carriage guide mechanism 9, between the guide devices 2 on both sides The sliding frame 13 is fixed, and the sliding frame 13 moves up and down under the action of the guiding device 2. Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap