Electric transmission type comprehensive inspection vehicle for railway

A technology of electric transmission and inspection vehicles, which is applied in the direction of railway inspection vehicles, railway vehicles, railway car body parts, etc., can solve the problems of low utilization rate of working skylights, scattered detection and monitoring resources, and affecting the detection efficiency of inspection vehicles, etc., to achieve detection The effect of comprehensive project, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

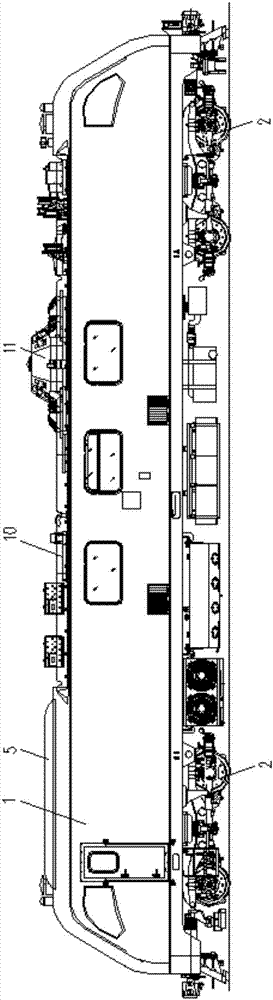

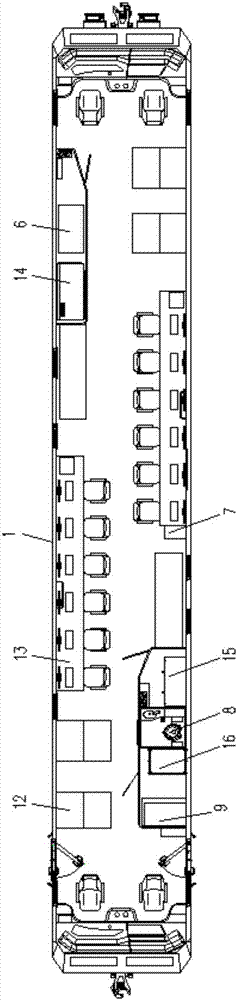

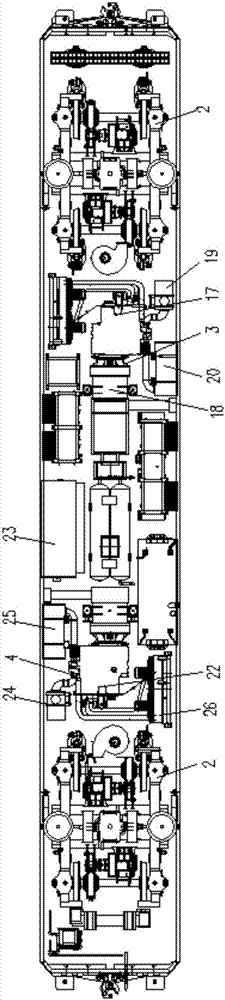

[0017] Attached below Figure 1-3 An embodiment of the present invention is described.

[0018] The railway electric transmission comprehensive inspection car has a car body 1, the car body 1 is installed on the power bogie 2 through the frame, and the top of the car body 1 and the inside of the car body 1 are equipped with living facilities and maintenance and inspection The front and rear ends of the car body 1 are provided with electrical interfaces and external sockets for easy connection with external vehicles and electrical equipment. The bottom of the car body 1 is equipped with a power system I3 and a power system II4. The power system I3 and the power bogie 2. It is connected with the driving control unit that controls the operation of the whole vehicle and the power system II4 is connected with the living facilities and the maintenance and repair detection unit to realize the independent power supply mode of the whole vehicle operation and the living facilities and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com