A kind of ultrasonic extraction method and application of partridge polysaccharide

An extraction method, the technology of partridge, which is applied in the field of food processing, can solve the problems such as the extraction of polysaccharides from seaweed partridge, and achieve the effects of good antioxidant activity, improved utilization rate, and short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for ultrasonically extracting partridge polysaccharides in this embodiment operates as follows:

[0033] According to the solid-liquid ratio of 1:20-60 (g:mL), add distilled water to the pretreated partridge mashed with a tissue masher, and perform ultrasonic treatment in ultrasonic, ultrasonic power 100-500w, extraction temperature 20-70℃, processing time 4-48min, centrifugal separation, the supernatant is partridge polysaccharide extract, the sediment is partridge residue, save the supernatant, get the first extraction of polysaccharide solution, the sediment is pressed Add water with the same solid-liquid ratio and repeat the above operation to obtain the second and third polysaccharide extracts, which are combined and constant volume to obtain the polysaccharide extract of partridge ultrasonic extraction. The extraction rate of partridge polysaccharide was obtained by calculation.

[0034] The phenol-sulfuric acid method was used to measure the polysaccharide...

Embodiment 2

[0038] This example is an optimization experiment of the extraction conditions for ultrasonic extraction of partridge polysaccharides.

[0039] (1) Single factor experiment of ultrasonic extraction of polysaccharides from partridge

[0040] ①The effect of ultrasonic power on the extraction rate of partridge polysaccharide

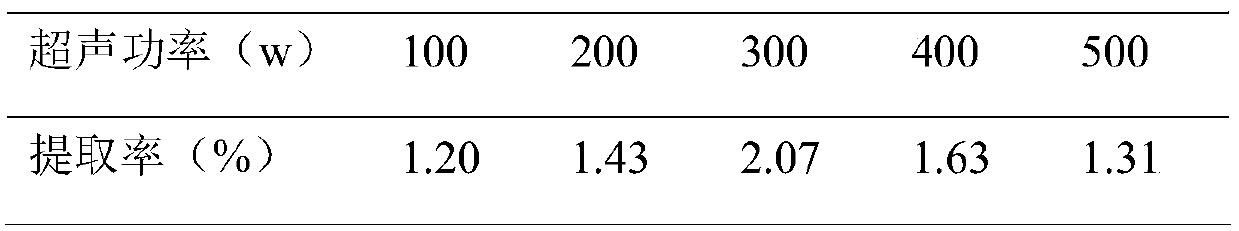

[0041] The extraction method steps are the same as in Example 1. The solid-to-liquid ratio, temperature, and ultrasonic time are respectively 1g:30mL, 20°C and 4min, the ultrasonic power is set to 100, 200, 300, 400 and 500w, and the number of extractions is once. The resulting polysaccharide The extraction rate is shown in Table 1:

[0042] Table 1

[0043]

[0044] It can be seen from Table 1 that when the ultrasonic power is 300w, the extraction rate of partridge polysaccharide is higher, and 250w, 300w, and 350w are selected as the level of orthogonal experiment.

[0045] ②The effect of solid-liquid ratio on the extraction rate of partridge polysaccharide

[0046]...

Embodiment 3

[0074] 1) Obtain the partridge polysaccharide extract according to the optimal process conditions of Example 2;

[0075] 2) Concentrate the extract obtained in 1) with a rotary evaporator at 60°C until the volume of the concentrated solution is 1 / 6 of the volume before concentration;

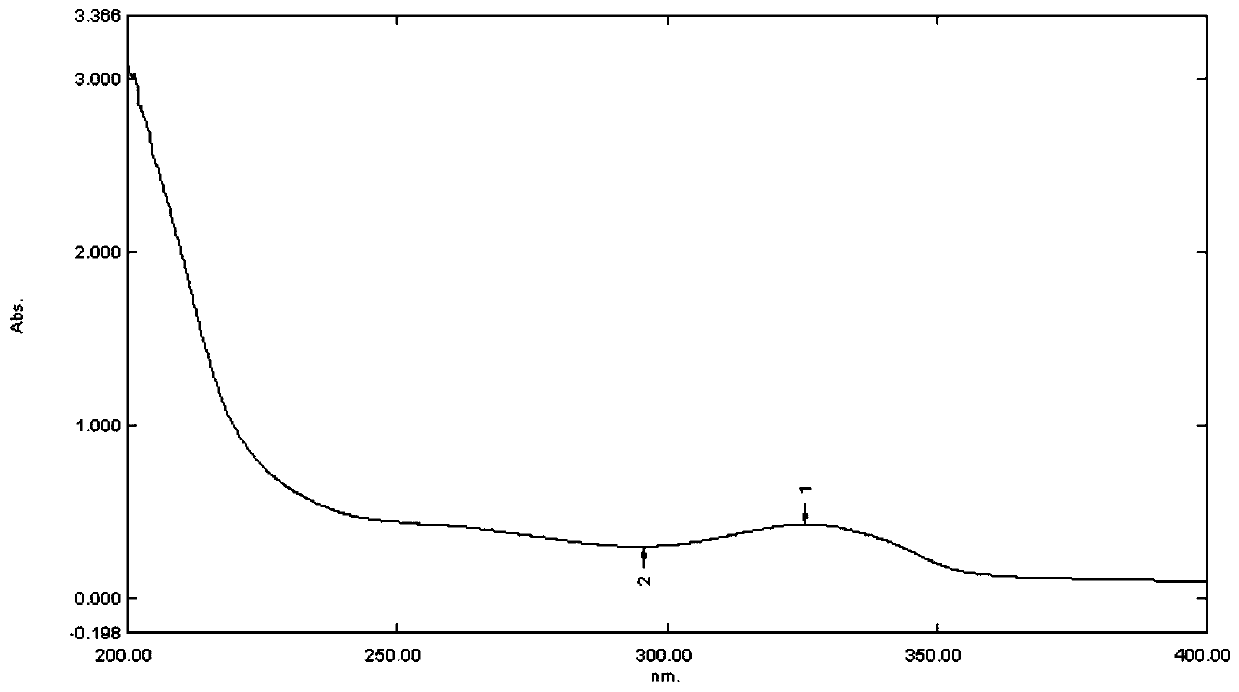

[0076] 3) Add sevag reagent to 2) concentrate, extract and separate the supernatant, remove 8 times, take a sample, and measure the UV absorption spectrum of sample 1, see figure 1 ;

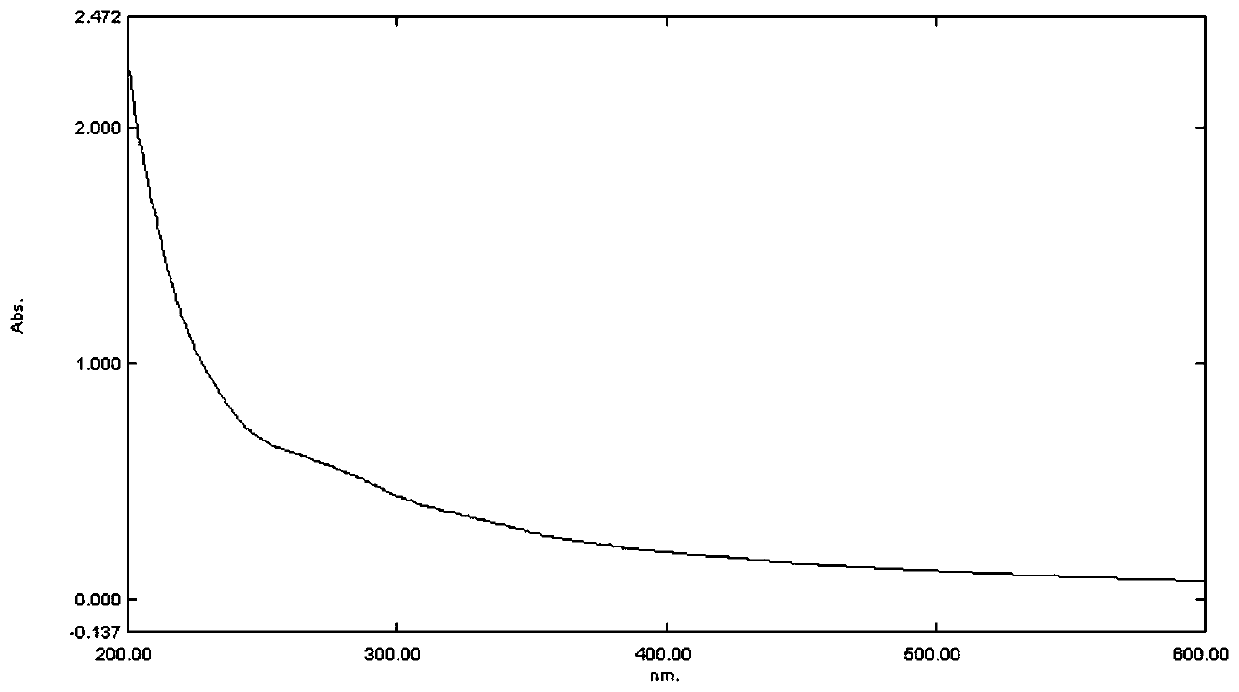

[0077] 4) Put the 3) deproteinized solution in a dialysis bag and dialyzed 3 times to obtain the partridge polysaccharide extract with kainic oxalic acid removed, take a sample, and measure the UV-visible absorption spectrum of sample 2, see figure 2 ;

[0078] From figure 1 It can be seen that the partridge polysaccharide extract after deproteinization has an obvious broad peak between 300-350nm; and figure 2 In this wavelength range, there is no absorption peak, indicating that the dialysis treatment can effectively re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com