Floor tile paving device and method

A technology for floor tiles and ceramic tiles, which is applied in the field of equipment for helping floor tiles to be laid flat, can solve problems such as insufficient laying efficiency, high flatness requirements, and poor laying effects, and achieves improved laying efficiency and good aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

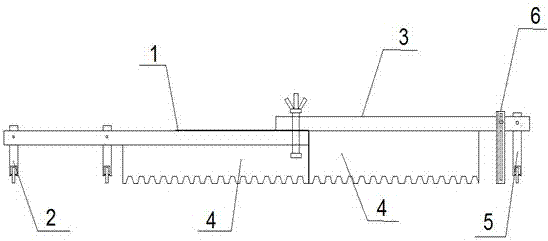

[0030] Such as figure 1 As shown, the floor tile laying device includes a frame. In order to adapt to the size of the floor tiles, it is convenient to adjust the specifications of the frame. The frame is composed of a first bracket 1 and a second bracket 3 .

[0031] Wherein the bottom of one end of the first bracket is provided with two main pulleys 2 with a certain distance. The other end of the first bracket is a connecting end for connecting with the second bracket. The connection end of the first bracket is provided with several connection through holes arranged side by side. A toothed scraper 4 is also provided between the two ends of the first bracket. Both the toothed scraper and the main pulley are connected with the first support by bolts.

[0032] It should be noted that, in the vertical direction, the position of the main pulley relative to the first bracket can change. That is, the main pulley includes a pulley frame and a pulley body installed at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com