Common style jacket and cutting method

A style and ordinary technology, applied in the field of ordinary style jackets and tailoring, can solve problems such as poor firmness and pullability, poor windproof performance of plackets, and insufficient aesthetics of jackets, etc., to improve windproof performance, solve poor windproof performance, and facilitate intuitiveness Recognition and effects of fixed-point operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

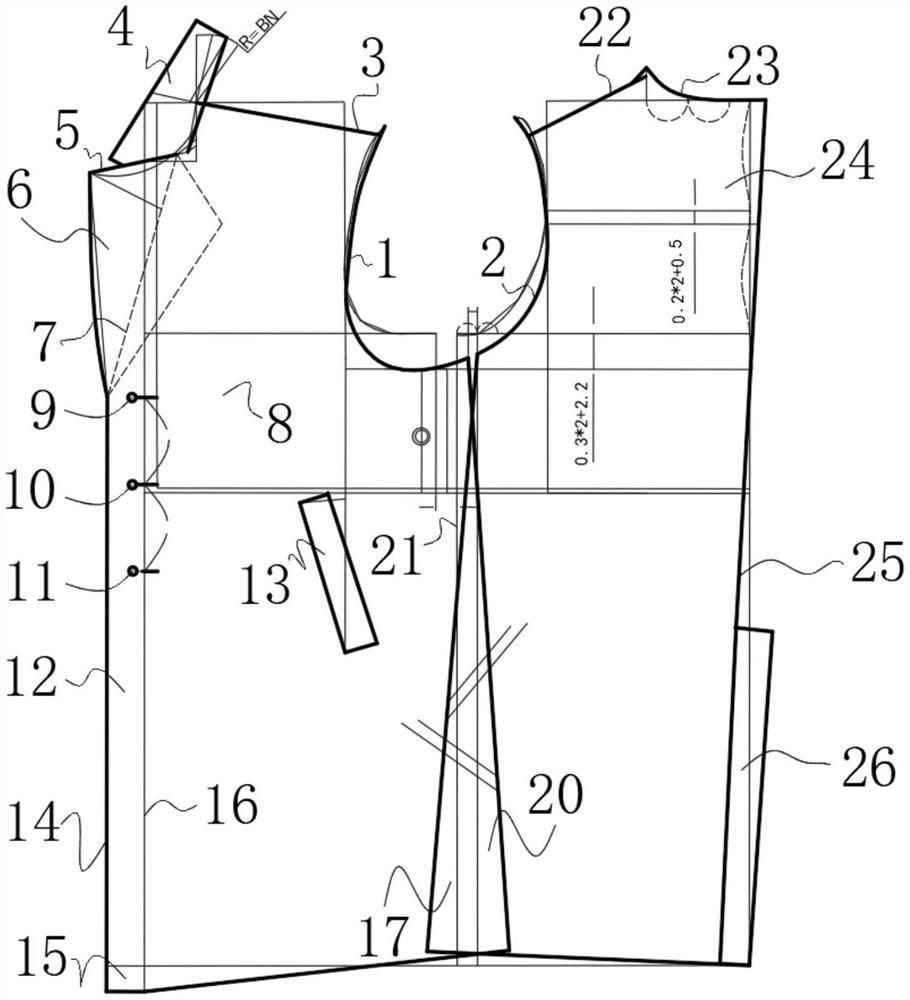

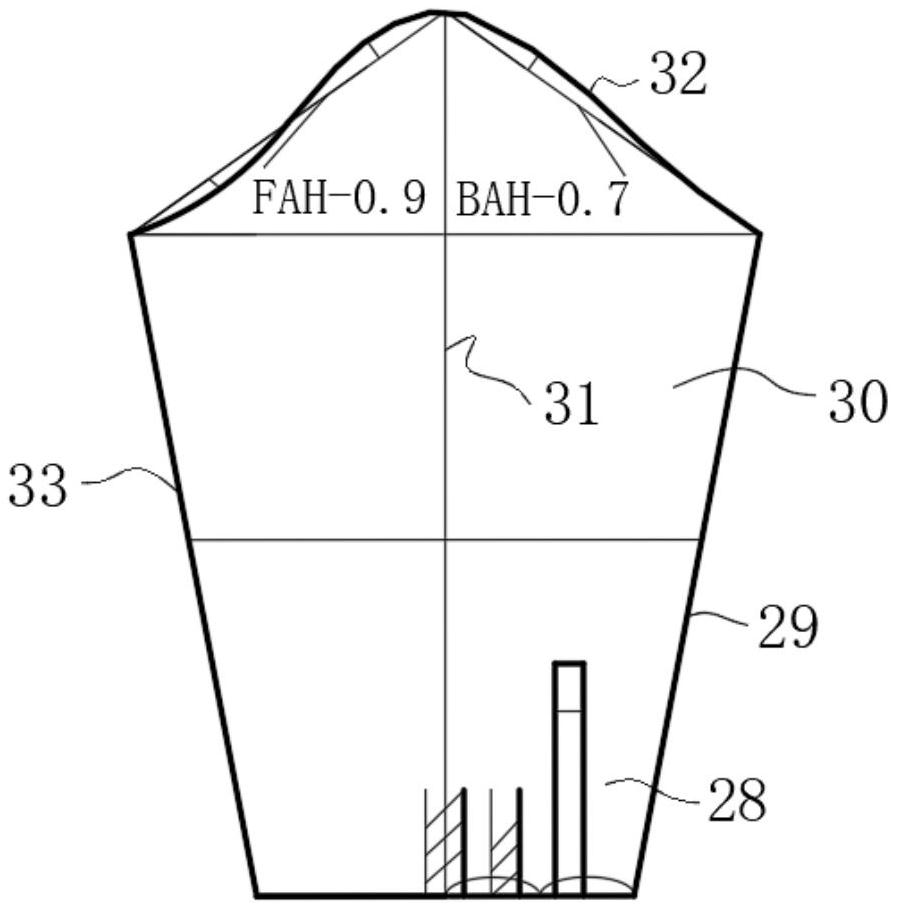

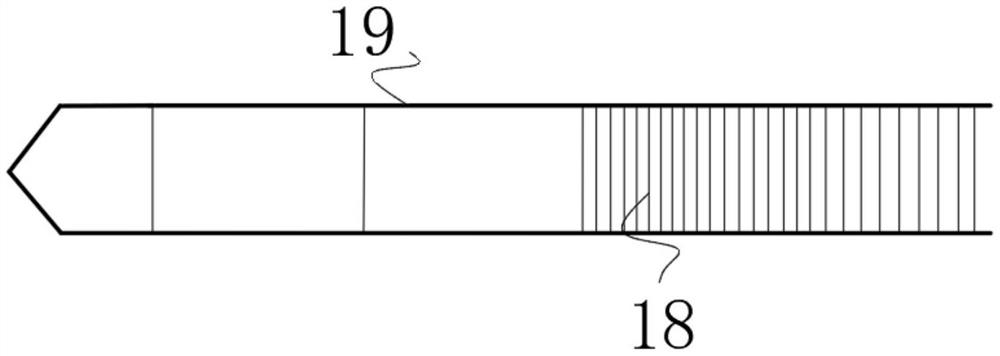

[0033] Such as Figure 1-4 As shown, the present invention provides a common style jacket, including the left front chest sleeve arc 1, the lower end of the left chest sleeve arc 1 is connected to the left chest sleeve arc 2, the upper end connection of the left thoracoke arc 2 There is a front shoulder strand 3, one end of the front shoulder track 3 is connected to the upper left tie 4, the lower end of the left top piece 4 is connected to the front lead 5, the lower end of the front neckline line 5 is connected to the lower left, left One end of the collar 6 is connected to the collar pleat line 7, the lower end of the collar pleat line 7 is connected to the left chest 8, and one end of the left chest front piece 8 is connected to the upper grain buckle 9, and the lower end of the top buckle 9 is connected. The lower end of the medium buckle 10, the lower end of the medium buckle 10 is connected to the lower buckle 11, and one end of the lower buckle 11 is connected to the lamina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com