Superfine all-tailing paste filling system and method

A technology of paste filling and full tailings, which is applied in filling materials, safety devices, earthwork drilling and mining, etc., can solve the problems of easy running and mixing, low underflow concentration, and fine particle size of ultra-fine full tailings, so as to relieve intermittent filling Contradictions, reduce investment costs, avoid the effects of raking accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0020] Aiming at the problems of low filling concentration and poor filling effect existing in the existing ultrafine tailings filling process, the invention provides an ultrafine full tailings paste filling system and method.

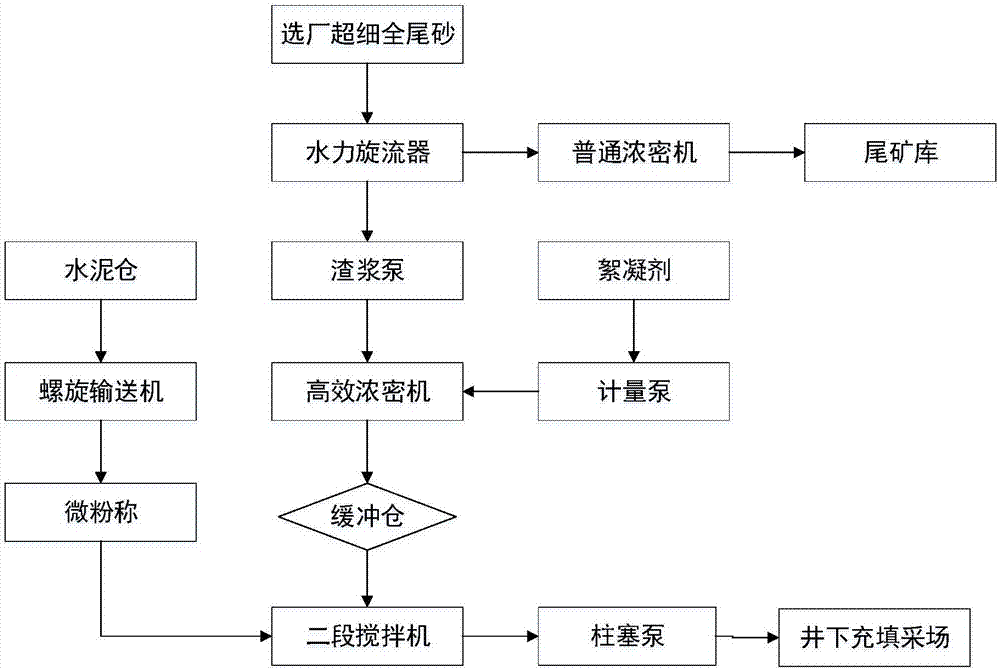

[0021] The system includes a full tailings grading system and a graded tailings paste filling system. The full tailings grading system includes a hydrocyclone. In the tailings pond, the underflow enters the graded tailings paste filling system; the graded tailings paste filling system includes a high-efficiency thickener, a buffer bin, a primary mixer, a secondary mixer and a plunger pump. The high-efficiency thickener is connected to the buffer bin through pipelines , the buffer bin is connected with the first-stage mixer, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com