Thickener underflow conveying and maintenance system

A machine underflow and thickener technology, which is applied in the direction of lifting device, settling tank feeding/discharging device, chemical instruments and methods, etc., can solve the problems of increasing the investment of the concentrator, increasing the cost of the thickener, and difficult construction, etc. Achieve the effects of avoiding rake accidents, improving safety and flexibility, and making construction difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with embodiment.

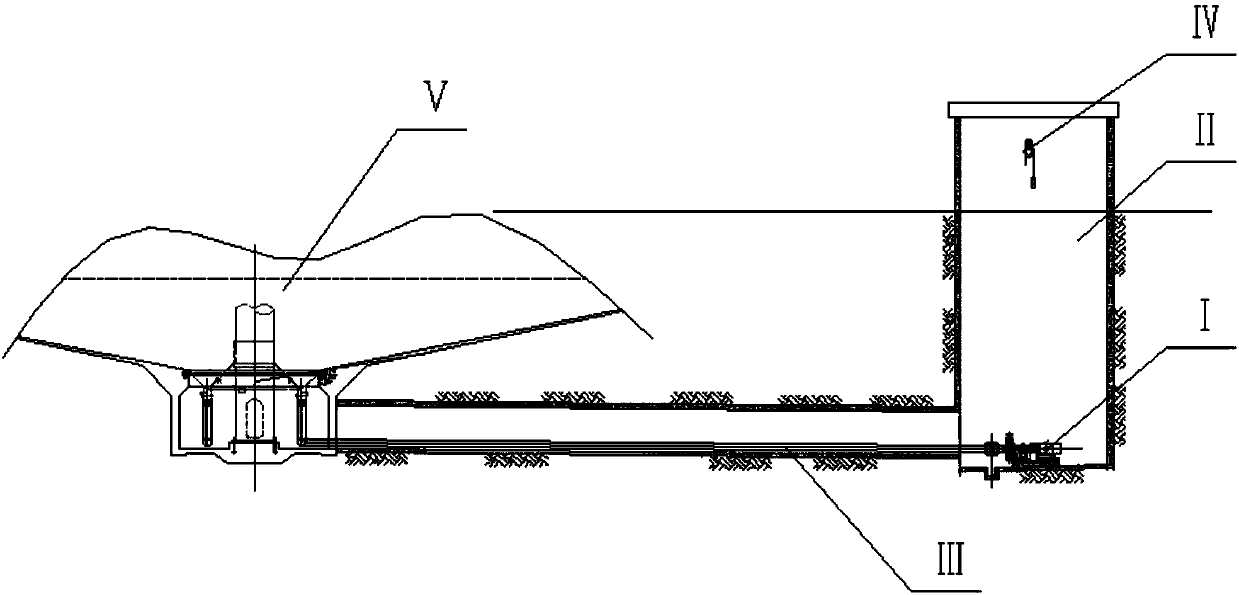

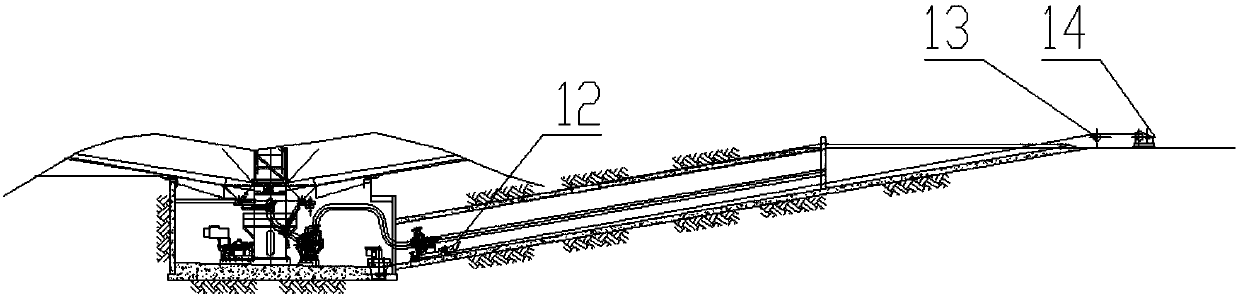

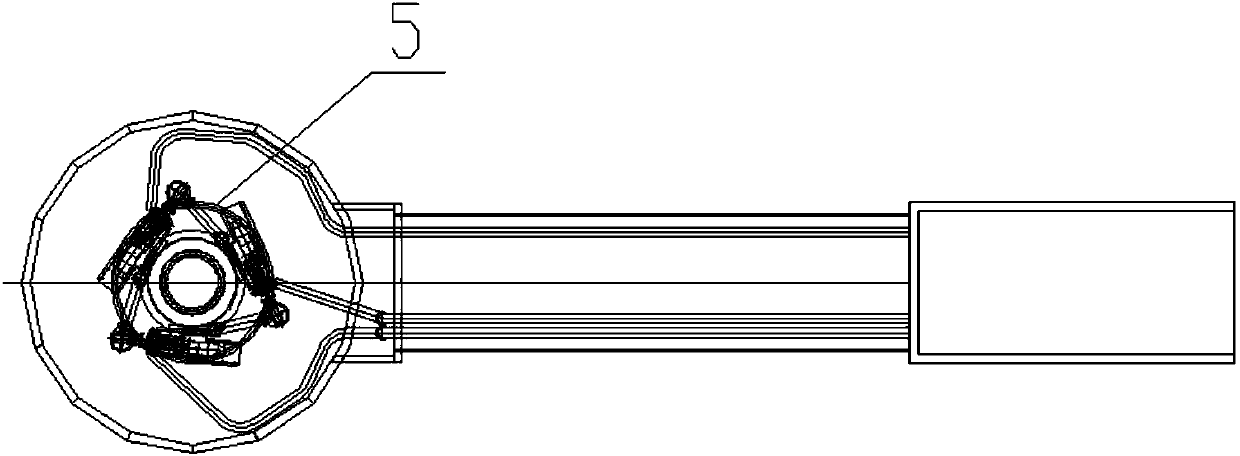

[0038] according to Figure 2 ~ Figure 4 As shown, a thickener underflow conveying and maintenance system provided by the present invention includes a thickener and a maintenance system. The bottom of the thickener 1 is provided with an underflow discharge port 2, and a high-pressure water discharge port 2 is provided above the underflow discharge port 2. Flushing port 3, an underflow pump 8 is installed in the underflow chamber below the thickener 1, the underflow discharge port 2 and the underflow pump 8 are communicated through the underflow pump inlet pipeline 7, and the underflow pump inlet The pipeline 7 is provided with a knife gate valve 6, and the maintenance system includes an electric hoist 7, a flatbed truck 12 and a hoist 14, and an electric hoist track is installed at a position corresponding to the underflow pump 8 on the top of the underflow chamber, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com