A customized pulse load test system and method based on gradient aluminum foam

A technology of load test and aluminum foam, which is applied in the field of pulse load test loading, can solve problems such as the inability to control waveforms, and achieve the effects of saving test costs, considerable economic benefits, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

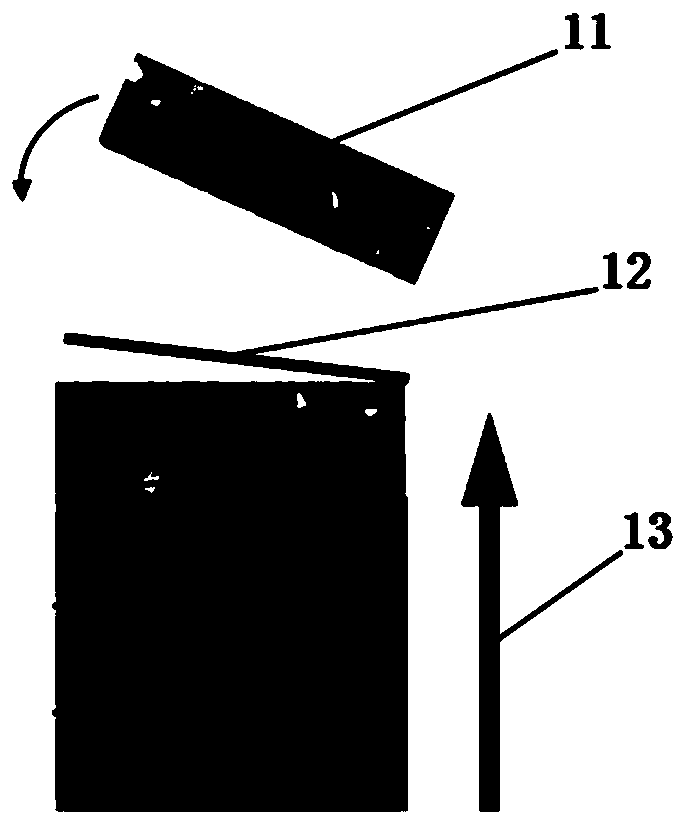

[0050] to get attached Figure 4As shown in the triangular waveform, first design the gradient sequence of the gradient aluminum foam projectile (in the form of density gradient) so that the relative density of the foam aluminum layer decreases linearly from 0.15 to 0.05 from the warhead to the tail.

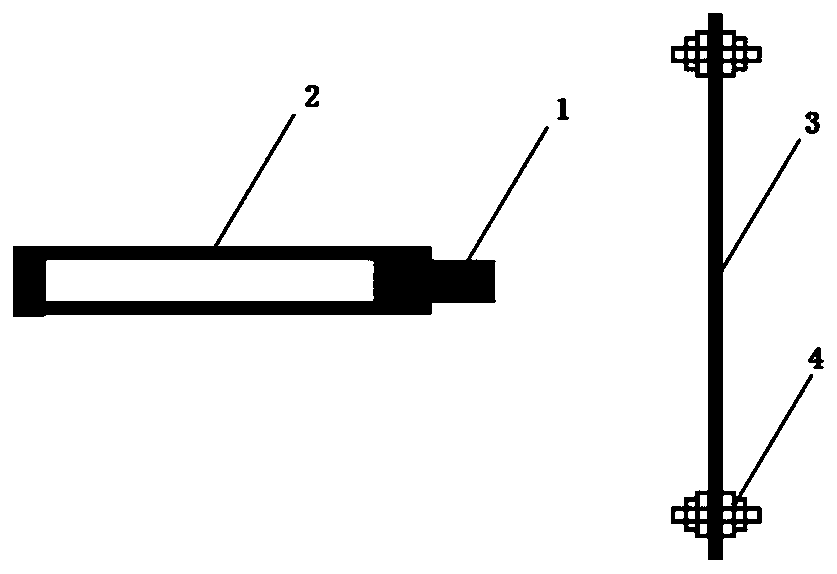

[0051] Cut ten kinds of aluminum foams with different densities (relative density is 0.05-0.15) into column blocks (including at least three cells) with a cross-sectional diameter of 57mm and a thickness of 10mm; stack each column block in turn according to the designed density gradient sequence In general, the layers are connected by flux-free brazing method, and the brazing material used is Zn-Al-Cu-based alloy, see figure 2 .

[0052] After the welding is completed, the gradient aluminum foam projectile is left to cool down, and then the surface of the gradient foam aluminum projectile is polished to make it smooth.

[0053] Finally, fill the gradient aluminum foam project...

Embodiment 2

[0055] to get Figure 5 The rectangular waveform shown in , firstly, the gradient sequence (in the form of density gradient) of the gradient foam aluminum projectile is designed so that the relative density of the foam aluminum layer increases linearly from 0.08 to 0.12 from the warhead to the tail.

[0056] Cut ten kinds of aluminum foams with different densities (relative density is 0.08-0.12) into column blocks (including at least three cells) with a cross-sectional diameter of 57mm and a thickness of 10mm; stack each column block in sequence according to the designed density gradient sequence In general, the layers are connected by flux-free brazing method, and the brazing material used is Zn-Al-Cu-based alloy, see figure 2 .

[0057] After the welding is completed, the gradient aluminum foam projectile is left to cool down, and then the surface of the gradient foam aluminum projectile is polished to make it smooth.

[0058] Finally, fill the gradient aluminum foam proj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com