Bidirectional alignment laser centering adjustment device and centering method

A laser centering and adjusting device technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of poor accuracy of centering results and cumbersome and complicated centering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

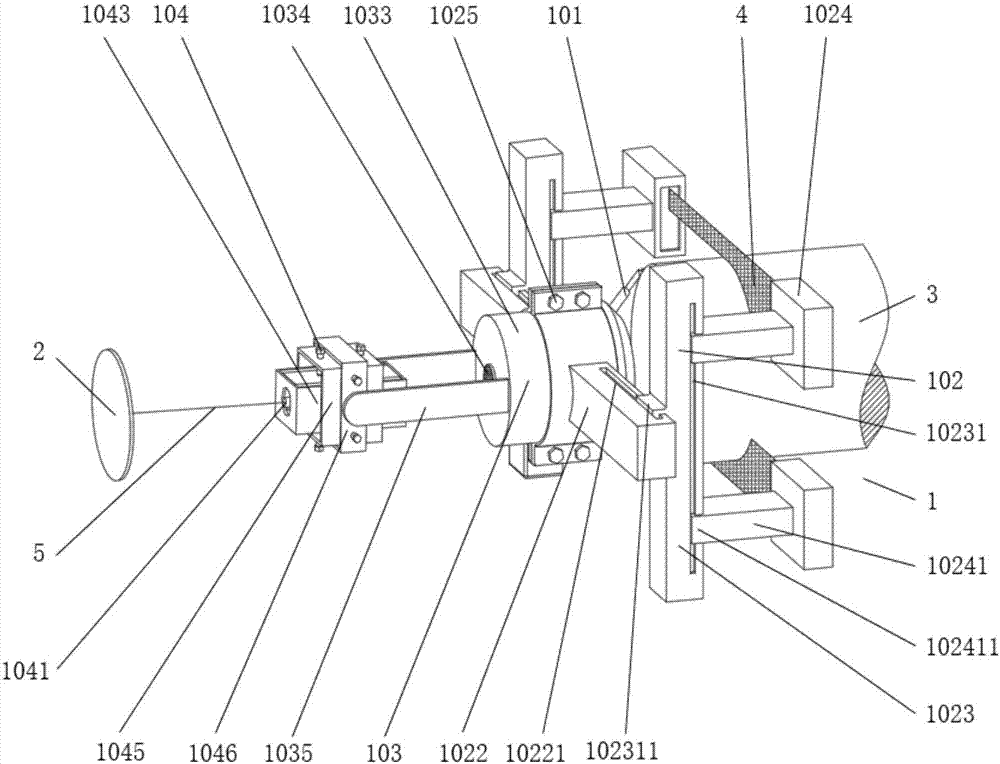

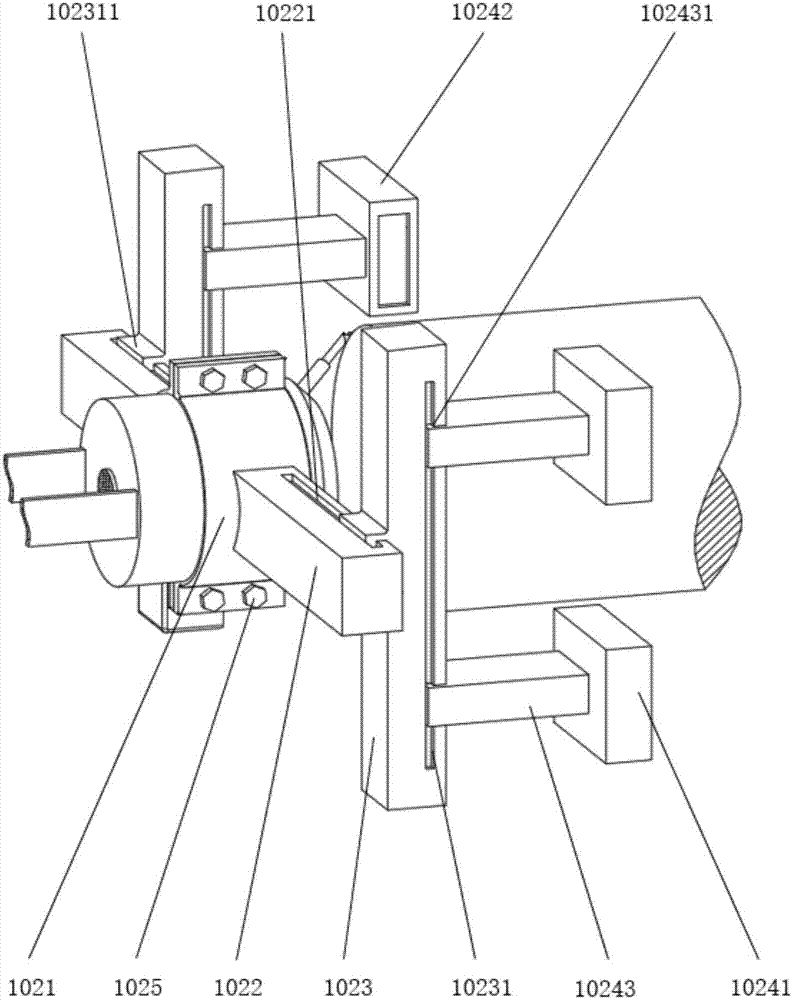

[0073] The two-way alignment laser centering adjustment device is composed of a fixed foot, a diameter measuring rear wing, a fixed laser receiving cylinder and a reversible laser macro and micro adjustment box, wherein the diameter measuring rear wing 102 is fixedly connected with the fixed laser receiving cylinder 103, and the fixed foot 101 is fixed on the fixed laser receiving tube 103, and the reversible laser macro-fine adjustment box 104 is fixedly connected with the fixed laser receiving tube 103.

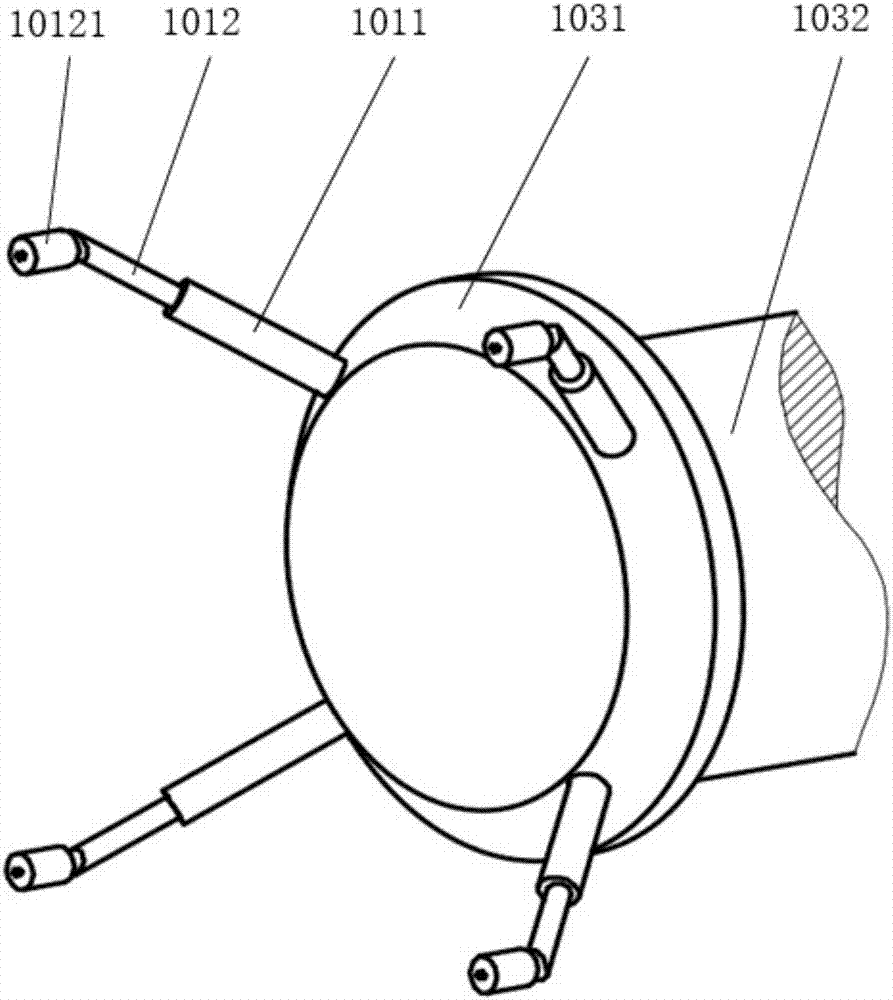

[0074] Such as figure 1 , figure 2 As shown, the fixed leg support 101 is composed of four fixed legs 1011 and four movable legs 1012; the diameter measuring rear wing 102 is connected with the fixed laser receiving cylinder 103 through the rotating shaft sleeve 1021, and is arranged on it The horizontal adjustment guide rail 1022 and the vertical adjustment guide rail 1023 adjust the high-precision CCD measurement receiver 1024, which can realize the diameter measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com