Device and method for testing force of rail vehicle carriages on chassis

The technology of a rail transit vehicle and a test device is applied in the field of the test device for the force exerted by the carriage of the rail transit vehicle on the underframe, which can solve the problems of deviation between weight and theoretical weight, difficulty, and limitation, and achieves high detection and test accuracy. , Satisfy the effect of empty spring spacing and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

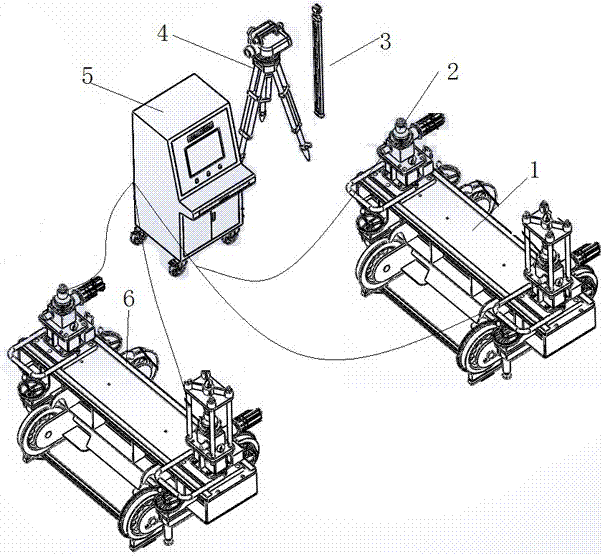

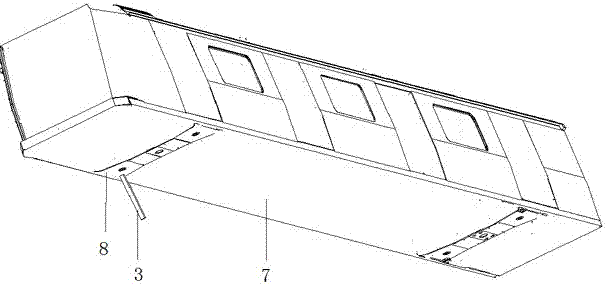

[0034] As shown in the accompanying drawings, a test device for the force of the rail transit vehicle compartment 7 on the underframe, including an underframe vehicle, an indium steel ruler 3, an electronic level 4 and a control device 5;

[0035] The undercarriage includes a crossbeam 1 with a wheel set at the bottom, and a weighing unit 2 is arranged on both ends of the top of the crossbeam 1 through slide rails 6. The weighing unit 2 is provided with a servo transmission mechanism connected to the control device 5; the weighing unit 2 and The servo drive mechanisms are respectively connected to the control device 5 .

[0036] The electronic level and the indium steel ruler 3 with the magnetic force base are used to measure the level difference of the compartment 7 support points.

[0037] A method for testing the force applied to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com