A Method for Measuring the Relaxation Activation Energy of Bulk Metallic Glass Structures

A technology of structural relaxation and metallic glass, applied in testing metals, measuring devices, instruments, etc., can solve the problem of less data, and achieve the effect of intuitive data results and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

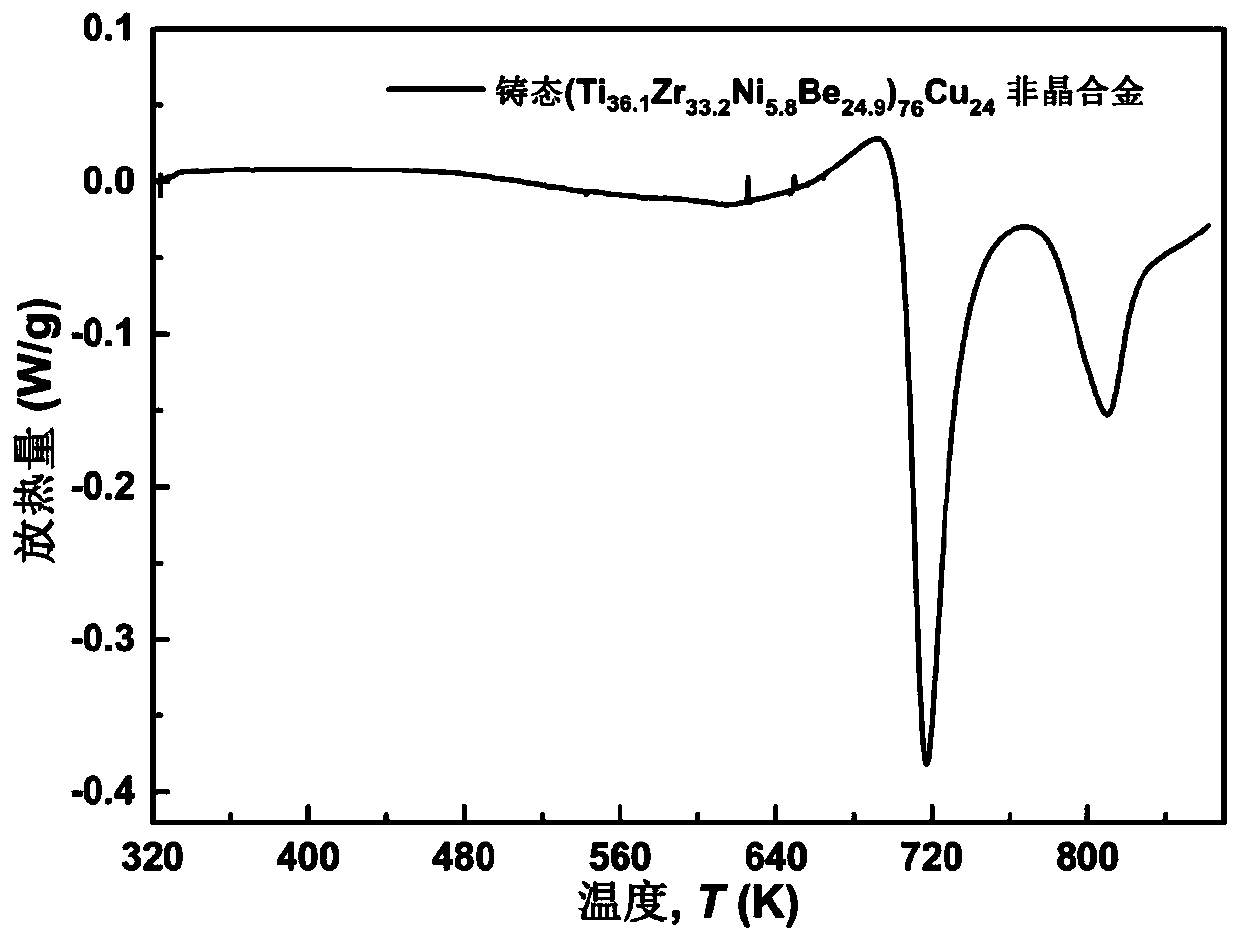

[0056] The sample is composed of (Ti 36.1 Zr 33.2 Ni 5.8 be 24.9 ) 76 Cu 24 cast bulk metallic glass with figure 1 It is its differential scanning calorimetry curve, from which it can be obtained that the glass transition temperature of the bulk metallic glass of this composition is about 650K; after a sample with a diameter of 5mm is made by suction casting with a copper mold, it is cut, ground and polished Finally, clean the two end faces with absolute ethanol, and finally dry the ethanol with an ear wash ball. Then put it into the DIL 402C thermal dilatometer. After the chamber is ventilated 3 times, open the calibration curve that has been tested in advance, and run the test program of heating and heat preservation.

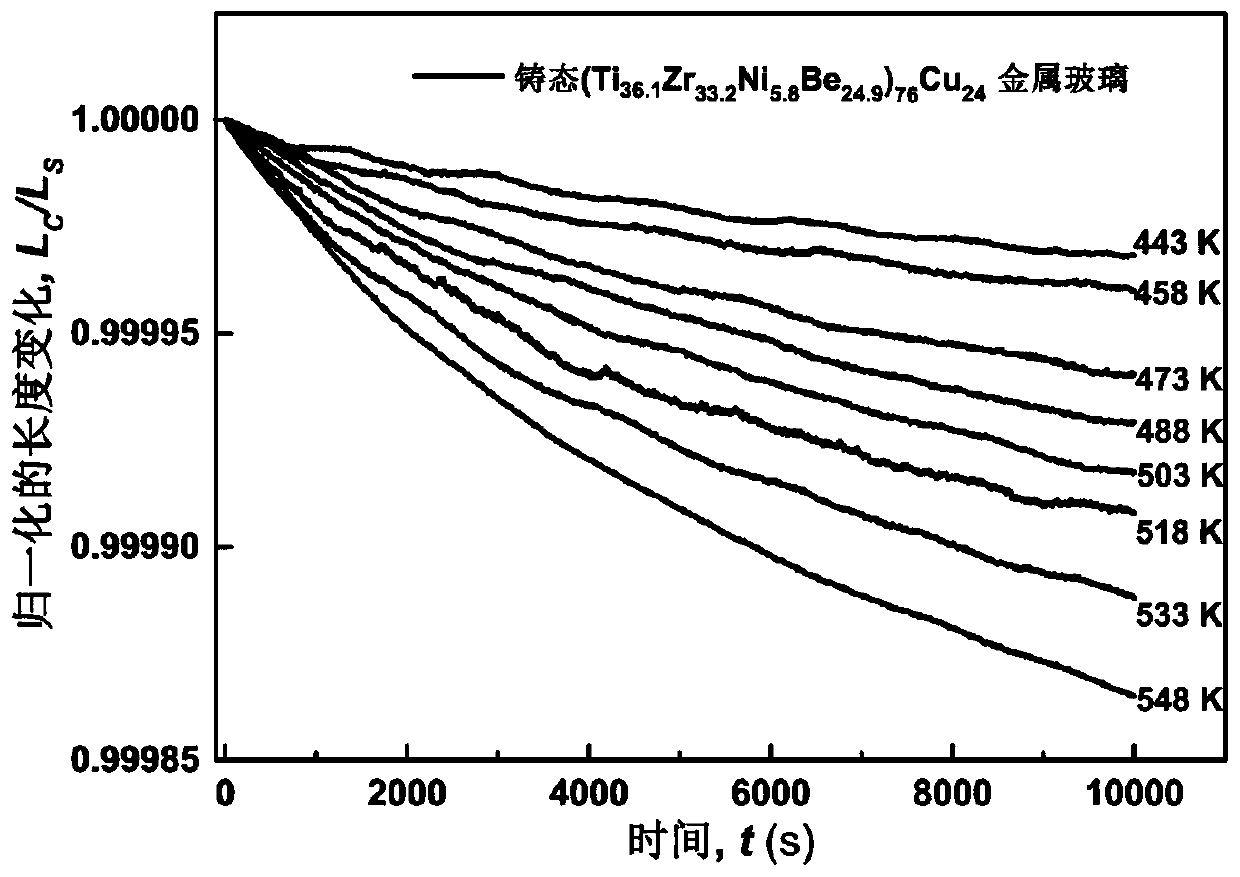

[0057] In 0.65-0.85 times the glass transition temperature (443K-548K), we selected 8 temperature points of 443K, 458K, 473K, 488K, 503K, 518K, 533K and 548K to test respectively. The obtained length change curve is attached as image 3 , where the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com