Working method of combined type industrial dust remover enabling air outlet to perform reverse dust blowing

A technology for industrial dust collectors and working methods, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of weak dust adsorption effect of filter bags, high dust removal efficiency, poor dust removal effect, etc. Processing time, the effect of enhancing the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

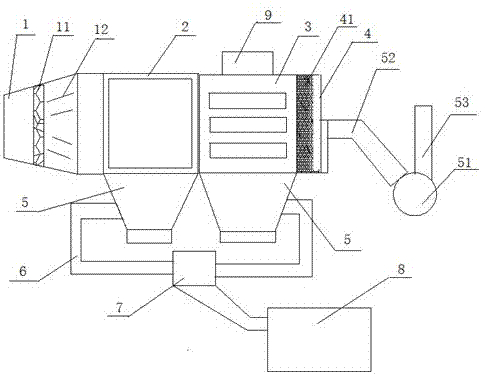

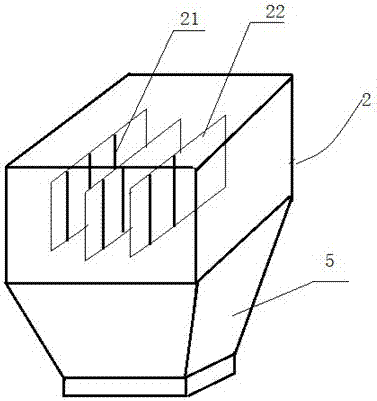

[0019] Such as figure 1 Shown is a working method of a combined industrial dust collector with reverse dust blowing at the air outlet. The combined industrial dust collector includes a dust air inlet 1, an electrostatic precipitator 2, a bag filter 3, a purified air outlet 4 and a blowback device 5. The dust air inlet 1 is set on the left side of the electrostatic precipitator 2, the bag filter 3 is set on the right side of the electrostatic precipitator to communicate with it, the purified air outlet is set on the right side of the bag filter 3, and the blowback device 5 is set on the purification 4 air outlets. Both the electrostatic precipitator 2 and the bottom of the bag filter 3 are provided with a dust collection tank 5, and the side of the dust collection tank 5 is also provided with a spray water pipe 6, and the other end of the spray water pipe 6 is connected to the water outlet of the water pump 7, and the water pump 7 The water inlet is connected with water storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com