Stirring device with stirring plate

A technology of stirring device and stirring plate, which is used in mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc., can solve the problems of material blockage and non-flowing, uneven mixing of materials, etc., to ensure transportability and reduce noise pollution. , Improve the effect of human control safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

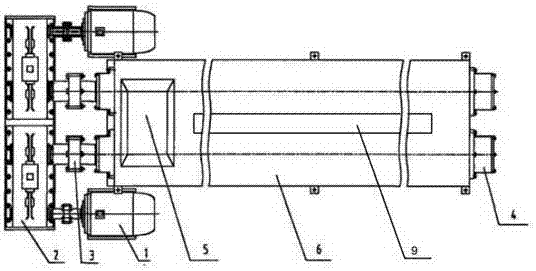

[0023] Such as Figure 1~6 As shown, a stirring device with a stirring plate includes a motor 1 and a stirring box 6, the output shaft of the motor 1 is connected to a reduction box 2, the output shaft of the reduction box 2 is connected to a coupling 3, and the coupling 3 is connected to a stirring shaft 4. The stirring shaft 4 is arranged in the stirring box 6, and the motor 1, the reduction box 2, the shaft coupling 3 and the stirring shaft 4 are arranged symmetrically around the center line of the stirring box 6 respectively. The structure connection of the device of the present invention is simple, easy to operate and stable Realize mixing without blind zone, good mixing and diversion effect, long service life, suitable for popularization and use.

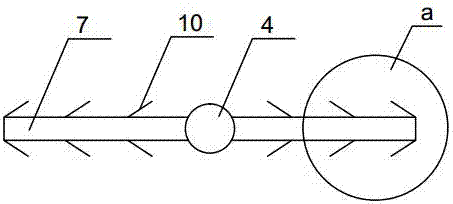

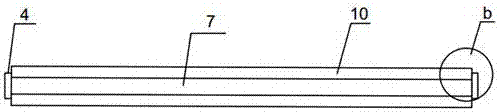

[0024] The surface of the stirring shaft 4 is obliquely connected with a stirring plate 7, the angle β between the stirring plate 7 and the stirring shaft 4 is 75°, the stirring shaft 4 is obliquely connected to the surface of...

Embodiment 2

[0032] Such as Figure 1~6 As shown, a stirring device with a stirring plate, in actual work, the motor 1 is turned on, and the material is continuously poured into the stirring box 6 through the feed port 5, and the motor 1 drives the coupling 3 to rotate through the reduction box 2, The coupling 3 drives the stirring shaft 4 to rotate, and the two motors 1 turn in the opposite direction and have the same speed, so that the stirring shaft 4 also rotates in the opposite direction but at the same speed, thereby driving the stirring plate 7 on the stirring shaft 4 to roll in the opposite direction. Stir the material in the opposite direction, and give the material a forward force while stirring, so that the material is pushed to the discharge port while being stirred. During the stirring process, the stirring situation inside the mixing box 6 can be observed in real time through the observation window 9 , place the collection device at the discharge port, the uniformly stirred m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com