Method for preparing ammonium perchlorate-metal salt composite based on sodium alginate curing

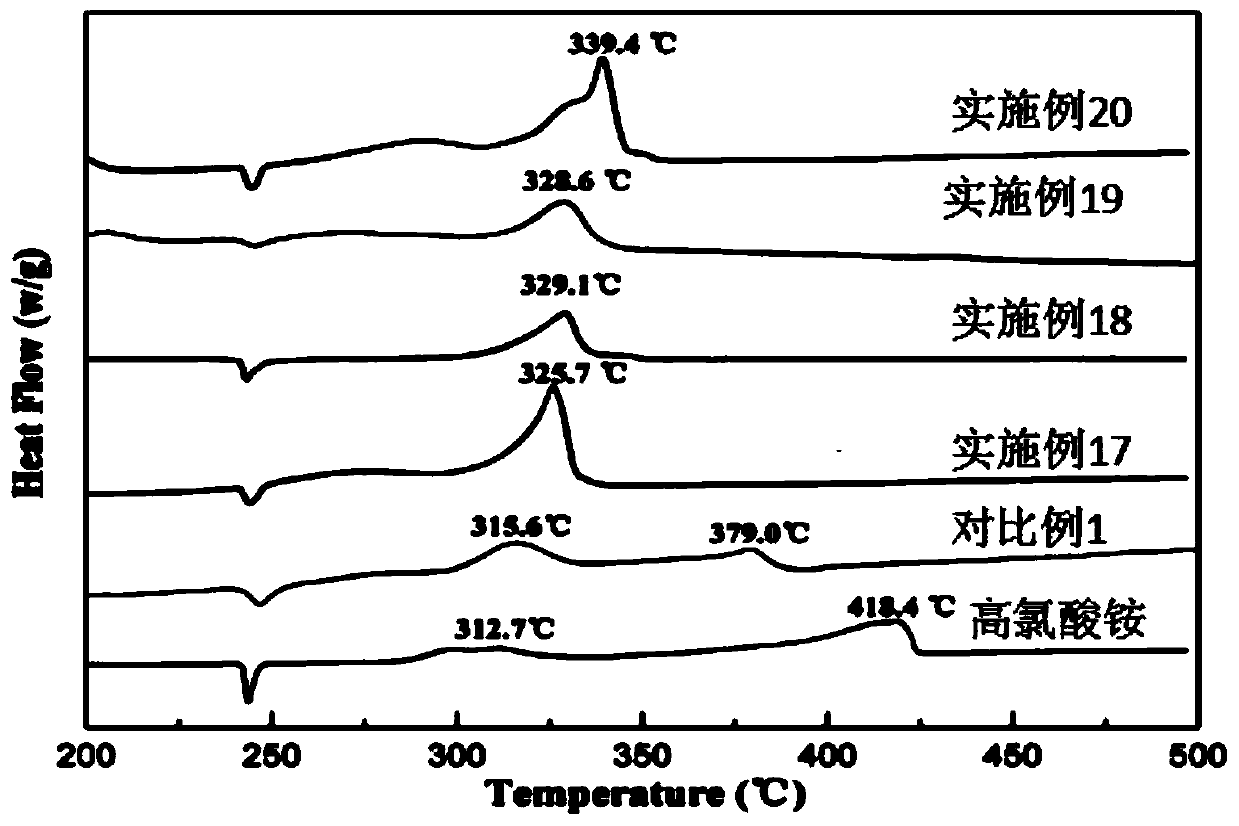

A technology of ammonium perchlorate and sodium alginate, which is applied in the direction of ammonium perchlorate composition, offensive equipment, compressed gas generation, etc., can solve the problem of high decomposition temperature, achieve early decomposition temperature, mild conditions, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing ammonium perchlorate-metal salt composite based on sodium alginate solidification, comprising the following steps:

[0029] Step 1. Disperse 1g of sodium alginate and 9g of ammonium perchlorate in 50mL of deionized water at a certain temperature and set aside;

[0030] Step 2, dissolving 2 g of cobalt nitrate in 20 mL of deionized water to obtain a cobalt nitrate solution for use;

[0031] Step 3. After absorbing the solution in step 1 with a syringe, disperse it in the cobalt nitrate solution in a dropwise manner to obtain a dispersion liquid;

[0032] Step 4: solidify the dispersion liquid, filter, wash, and dry at room temperature to obtain the compound. A thermal decomposition experiment was carried out on the compound, in which the decomposition temperature of ammonium perchlorate dropped to 324.8°C; in this experiment, ammonium perchlorate and sodium alginate were evenly compounded together in an aqueous solution, and sodium alginate and hi...

Embodiment 2

[0034] A method for preparing ammonium perchlorate-metal salt composite based on sodium alginate solidification, comprising the following steps:

[0035] Step 1. Disperse 1g of sodium alginate and 15g of ammonium perchlorate in 50mL of deionized water at a certain temperature and set aside;

[0036] Step 2, dissolving 2 g of copper nitrate in 30 mL of deionized water to obtain a copper nitrate solution for use;

[0037] Step 3, after absorbing the solution in step 1 with a syringe, disperse it in the copper nitrate solution in a dropwise manner to obtain a dispersion liquid;

[0038] Step 4: solidify the dispersed material, filter, wash, and freeze-dry to obtain the compound. The compound was subjected to thermal decomposition experiments, in which the decomposition temperature of ammonium perchlorate dropped to 330.8°C.

Embodiment 3

[0040] A method for preparing ammonium perchlorate-metal salt composite based on sodium alginate solidification, comprising the following steps:

[0041] Step 1. Disperse 0.5g of sodium alginate and 9g of ammonium perchlorate in 50mL of deionized water at a certain temperature, and set aside;

[0042] Step 2, dissolving 1 g of cobalt nitrate and 1 g of copper nitrate in 20 mL of deionized water to obtain a metal salt solution for use;

[0043] Step 3. Disperse the solution in step 1 in petroleum ether, stir it magnetically, and after forming a stable water-in-oil, slowly add the metal salt solution in step 2 dropwise to obtain a dispersed material liquid;

[0044] Step 4: solidify the dispersed material, filter, wash, and freeze-dry to obtain the compound. The compound was subjected to thermal decomposition experiments, in which the decomposition temperature of ammonium perchlorate dropped to 327.2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com