A nanocomposite energetic material and its preparation method

A nano-composite and composite catalyst technology, which is used in offensive equipment, explosives processing equipment, nitroalkane compositions, etc., can solve the problem that energetic materials cannot be used in engineering, the energy increase of composite energetic materials is limited, and the quality of wet gel is very high. Poor and other problems, to achieve the effect of eliminating the insulation process, shortening the gel time, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

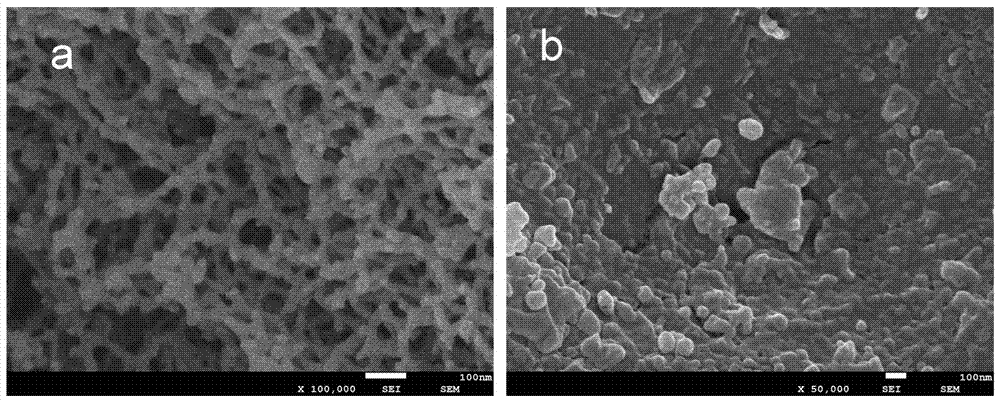

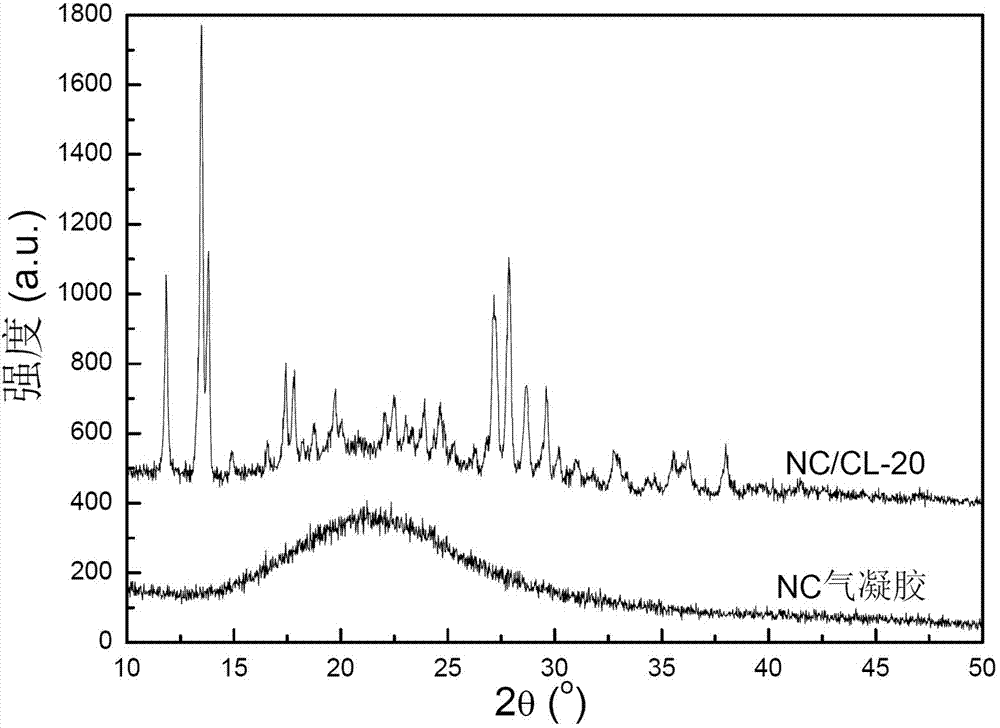

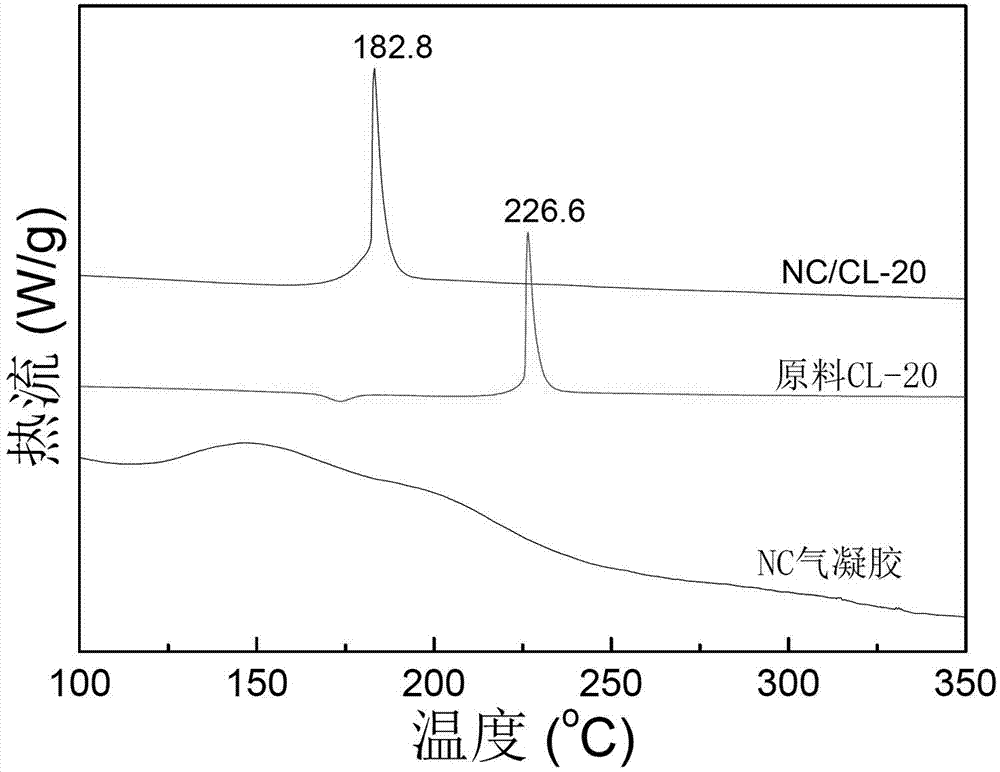

Embodiment 1

[0029]Take 1.5g of NC containing 11.8% nitrogen and 2.25g of CL-20 and dissolve them in 37.5mL of ethyl acetate to obtain a colorless and transparent mixed solution. Add 0.27mL TDI, 0.03mL T-12 and 0.045g TEDA to the mixed solution under stirring, stop stirring after completely dissolving. After standing still, the color of the solution gradually changed from colorless to yellow, and then to reddish brown. After 15-20 minutes, the solution turned into a stagnant, transparent dark reddish brown wet gel. The obtained wet gel was sealed, and aged under normal temperature and pressure for 10 days. Afterwards, the aged wet gel was placed in a supercritical autoclave and heated with SCF-CO at 50 °C and 9.5 MPa 2 The fluid is extracted and dried to obtain the CL-20 / NC nanocomposite energetic material.

Embodiment 2

[0031] Take 2.55g of NC containing 12.0% nitrogen and 1.7g of CL-20 and dissolve them in 43mL of tetrahydrofuran to obtain a colorless and transparent mixed solution. Add 0.46mL TDI, 0.10mL T-12 and 0.0425g TEDA to the mixed solution under stirring, stop stirring after completely dissolving. After standing still, the color of the solution gradually changed from colorless to yellow, and then to reddish brown. After 15-20 minutes, the solution turned into a stagnant, transparent dark reddish brown wet gel. The obtained wet gel was sealed, and aged under normal temperature and pressure for 10 days. Afterwards, the aged wet gel was placed in a supercritical autoclave and heated with SCF-CO at 45 °C and 10.0 MPa 2 The fluid is extracted and dried to obtain the CL-20 / NC nanocomposite energetic material.

Embodiment 3

[0033] Take 2.6g of NC containing 12.0% nitrogen and 1.3g of CL-20 and dissolve them in 39mL of tetrahydrofuran to obtain a colorless and transparent mixed solution. Add 0.47mL TDI, 0.12mL T-12 and 0.026g TEDA to the mixed solution under stirring, stop stirring after completely dissolving. After standing still, the color of the solution gradually changed from colorless to yellow, and then to reddish brown. After 15-20 minutes, the solution turned into a stagnant, transparent dark reddish brown wet gel. The obtained wet gel was sealed, and aged under normal temperature and pressure for 10 days. Afterwards, put the aged wet gel into a supercritical autoclave, and use SCF-CO at 40 °C and 9.0 MPa 2 The fluid is extracted and dried to obtain the CL-20 / NC nanocomposite energetic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com