Double-pulling open-type front cover lock operation mechanism

A lock operation and front cover technology, which is applied in the field of auto parts, can solve the problems of insufficient stability and reliability of the double zipper, and achieve the effects of compact structure, convenient operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

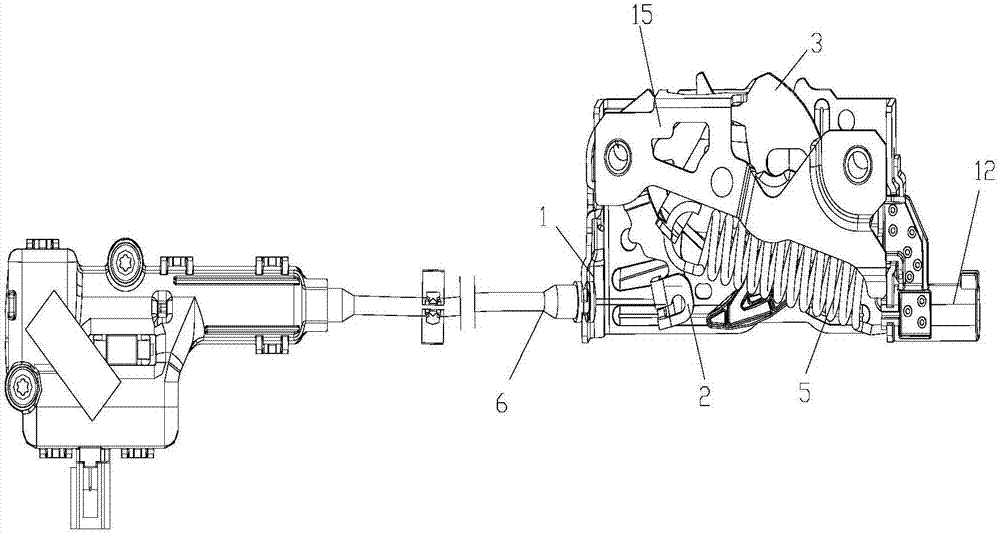

[0048] Such as figure 1 , the driving mechanism is a drag cable 6, and the drag cable 6 is connected with the ratchet 2 and pulls the ratchet 2 to move.

Embodiment 2

[0050] The driving mechanism is an electric unlocking mechanism 7 . Wherein, the electric unlocking mechanism 7 and the ratchet 2 can be connected by a drag cable 6 . Or use the following two methods: The first method: such as Figure 13 , the pawl 2 is fixed with a special connector 8, and the electric unlocking mechanism 7 is snapped connected with the special connector 8; the second way: as Figure 14-15 , The electric unlocking mechanism 7 is connected with a ball head 9, and the pawl 2 is provided with an arc-shaped groove 10 matching with the ball head 9. This structure can reduce friction.

Embodiment 3

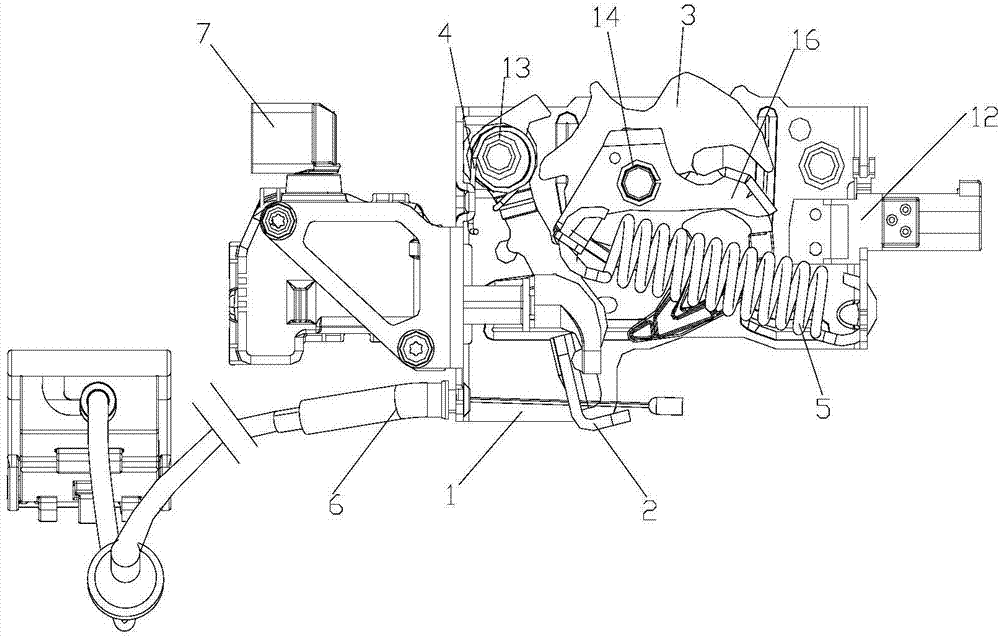

[0052] The driving mechanism includes an electric unlocking mechanism 7 and a drag cable 6 .

[0053] Such as Figure 1-2 The driving mechanism is that the base plate 1 of the electric unlocking mechanism 7 has an electric unlocking mechanism mounting frame, and the base plate 1 whose driving mechanism is the drag cable 6 does not have it, thereby switching between electric and manual modes.

[0054] Such as Figure 1-2 and Figure 17-19, the substrate 1 is provided with a connector 12, the connector 12 includes a micro switch 121, when the front cover lock is in the full lock state, the micro switch 121 is in the off state, when the front cover lock is in the half lock or unlocked state, the micro switch 121 The switch 121 is in an on state.

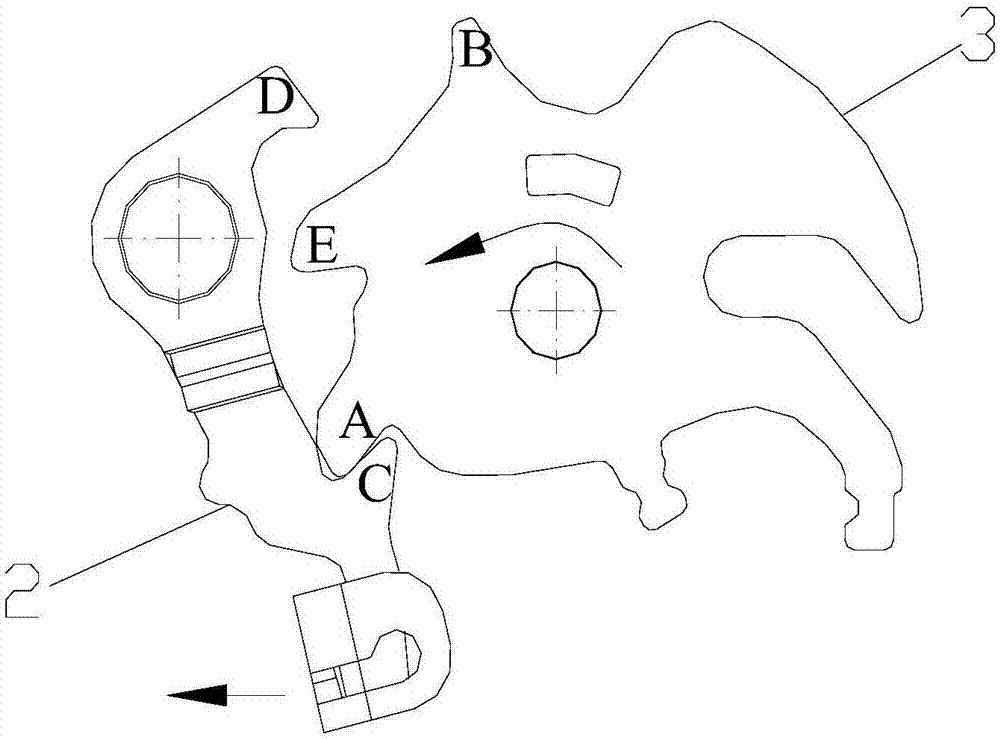

[0055] The pawl 2 is rotatably connected to the base plate 1 through the pawl rivet shaft 13 , the ratchet 3 is rotatably connected to the base plate 1 through the ratchet rivet shaft 14 , and an upper cover 15 is provided above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com