relay

A relay and electric contact technology, applied in relays, electromagnetic relays, non-polar relays, etc., can solve problems such as electrical corrosion and cost increase, and achieve the effects of improving electrical corrosion resistance, improving environmental resistance, and suppressing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

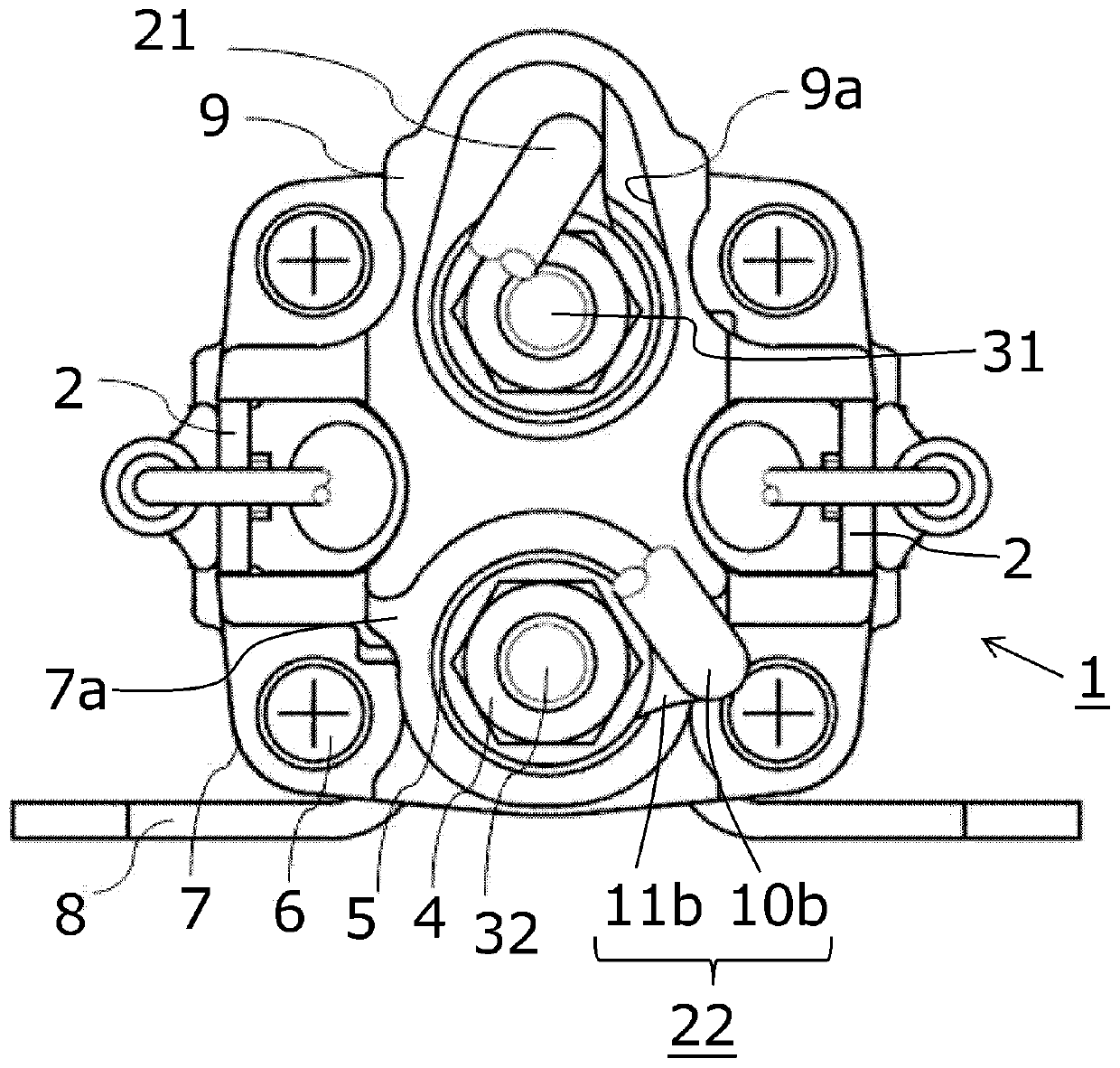

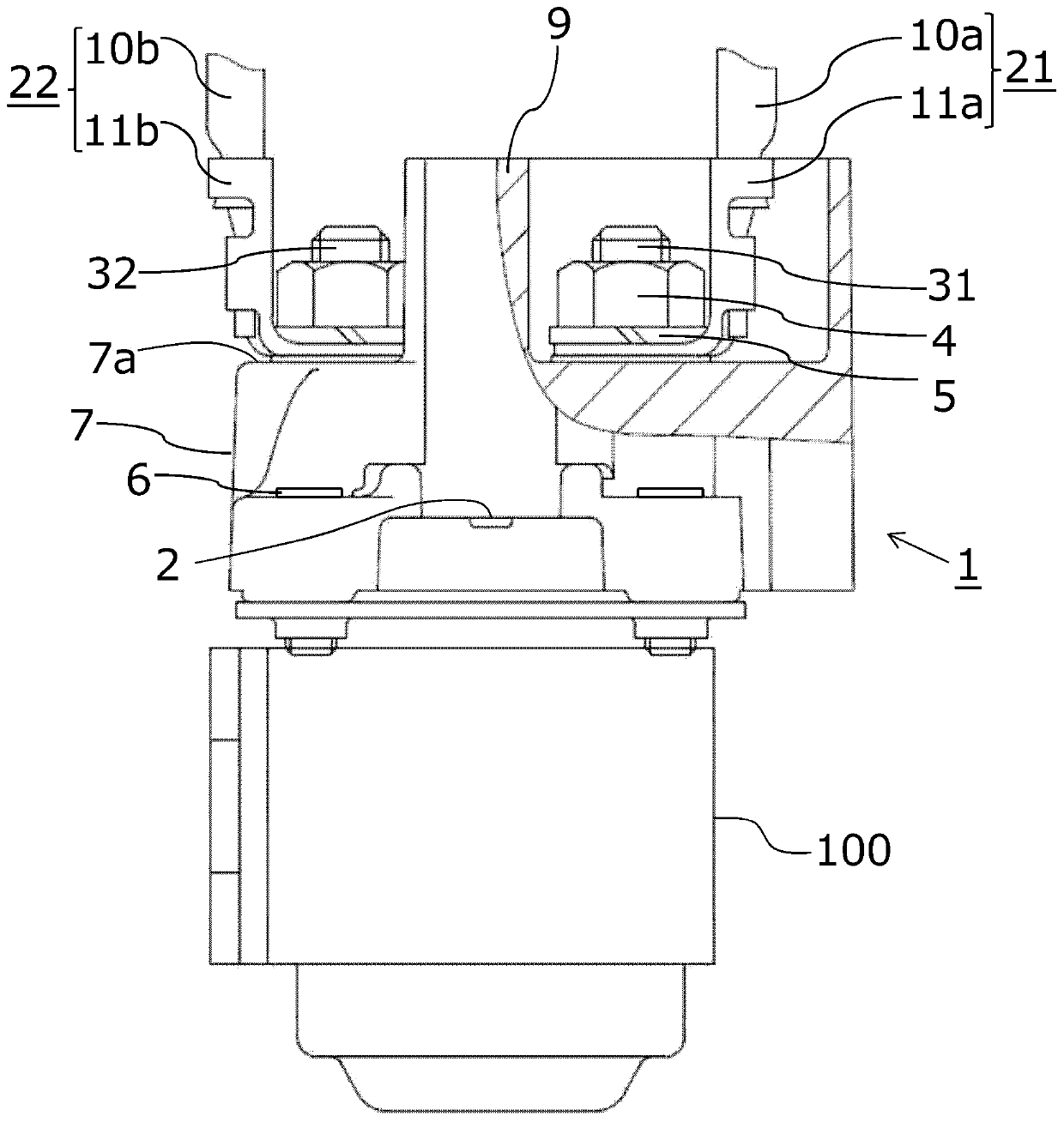

[0019] use figure 1 and figure 2 The relay 1 according to Embodiment 1 of the present invention will be described. figure 1 is the top view of relay 1, figure 2 is a sectional side view of the main part of the relay 1 . The above-mentioned relay 1 is, for example, a relay for switching on and off the current of the power supply system on the vehicle side.

[0020] Such as figure 1 As shown, in the relay 1 , main terminals 31 and 32 constituting a pair of main terminals are provided on the main surface portion side forming the front. The above-mentioned main terminals 31 and 32 are configured to be freely contactable and separated by electrical contacts (not shown) in the main body of the relay 1 . The above-mentioned electric contacts are driven by the excitation coil (not shown) in the main body of the relay 1, and as figure 1 As shown, an excitation terminal 2 connected to an excitation coil is provided on the main surface side of the relay 1 .

[0021] Here, the ma...

Embodiment approach 2

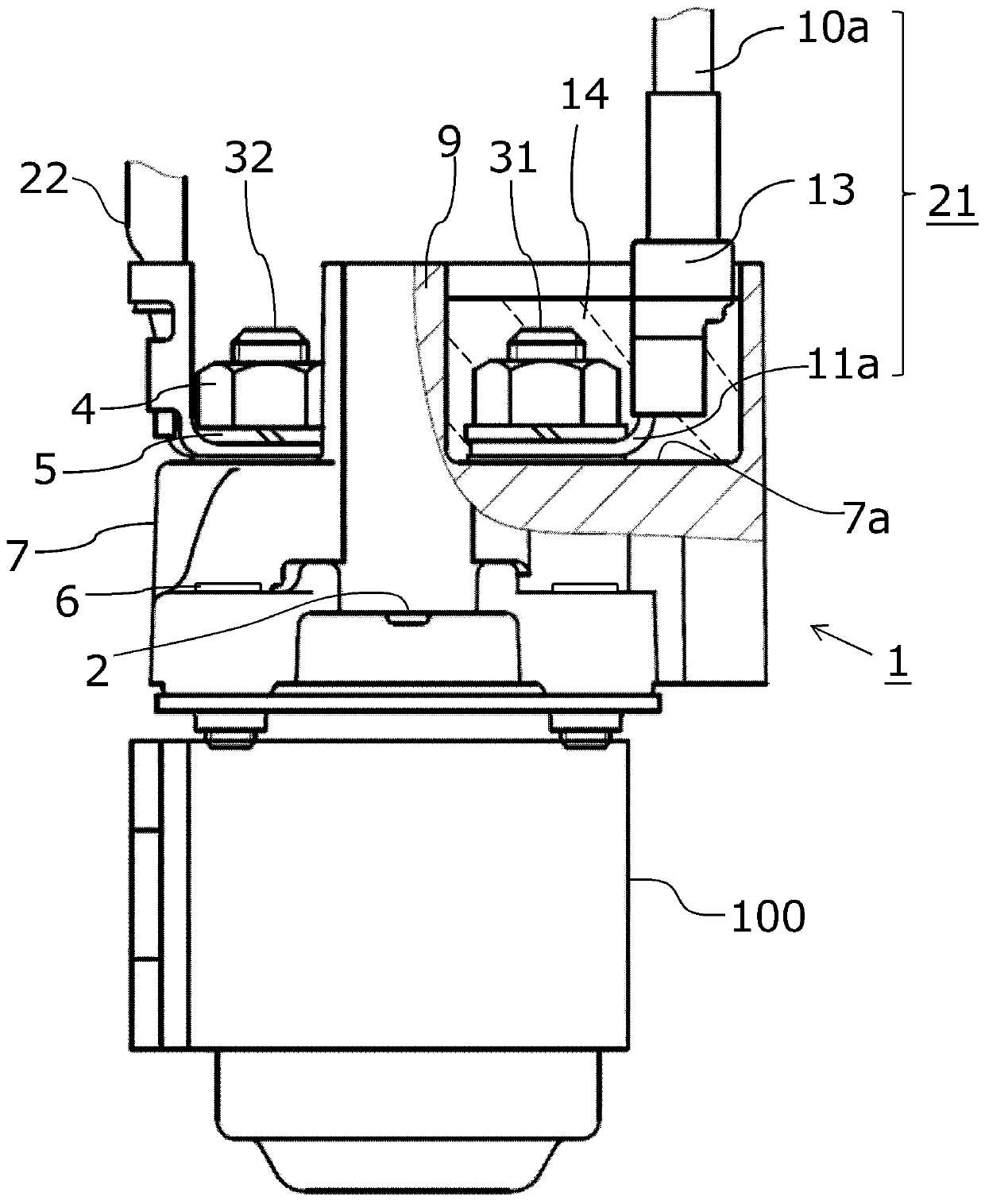

[0046] image 3 It is a cross-sectional side view of main parts of relay 1 according to Embodiment 2 of the present invention. In the relay 1 of the above-mentioned first embodiment, the case where the wiring 21 connected to the main terminal 31 is composed of the lead part 10a and the terminal part 11a connected to the end of the lead part 10a is exemplified, and the height of the partition wall part 9 is The height above the upper end of the terminal portion 11a. In Embodiment 2, the case where the wiring 21 constituting the relay 1 has a structure in which the insulating tube 13 is attached to the connecting portion between the connecting lead portion 10a and the terminal portion 11a will be described.

[0047] In the structure of the wiring 21, the terminal portion 11a fixed to the main terminal 31 is composed of a flat portion fastened by a nut 4 and connected to the main terminal 31, and a standing portion standing from the flat portion. and connected to the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com