Novel cable stripping machine

A technology for stripping machine and cable, which is applied in the direction of cable installation, cable installation device, and equipment for dismantling/armoring cables, etc., which can solve the problems of time-consuming and laborious, inaccurate cutting, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

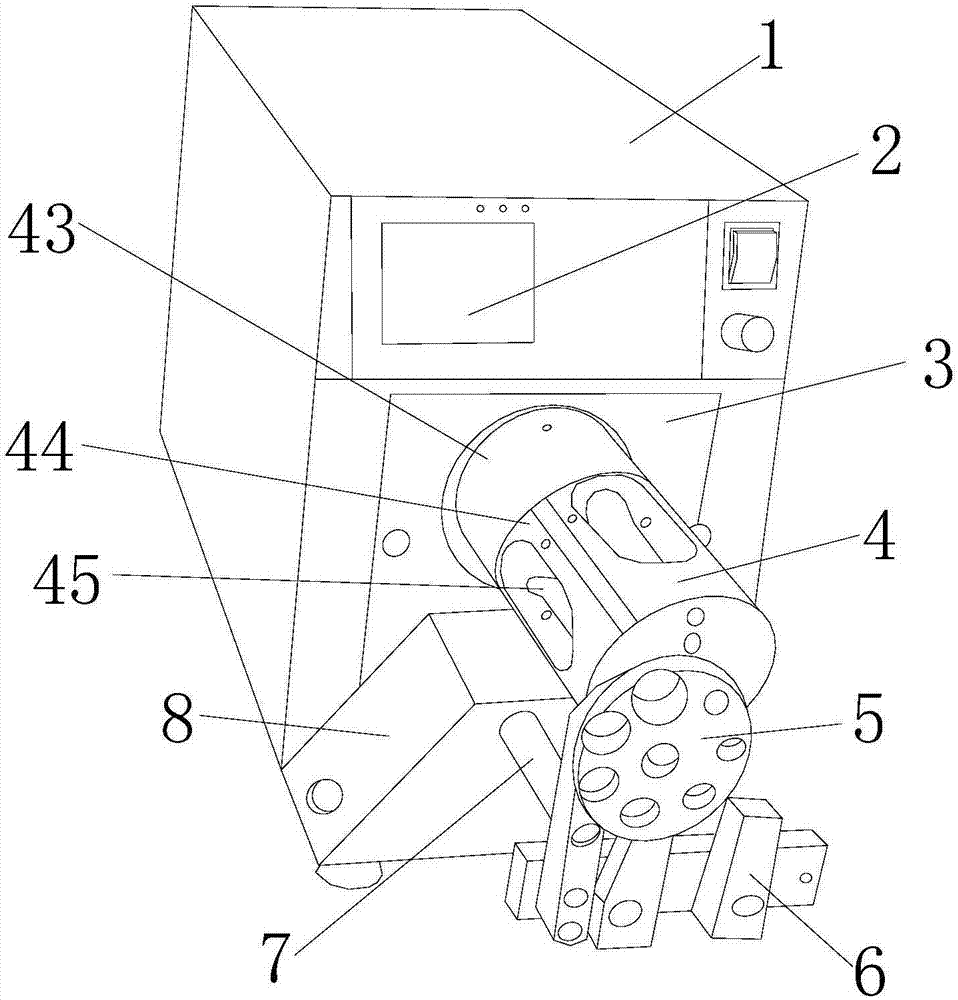

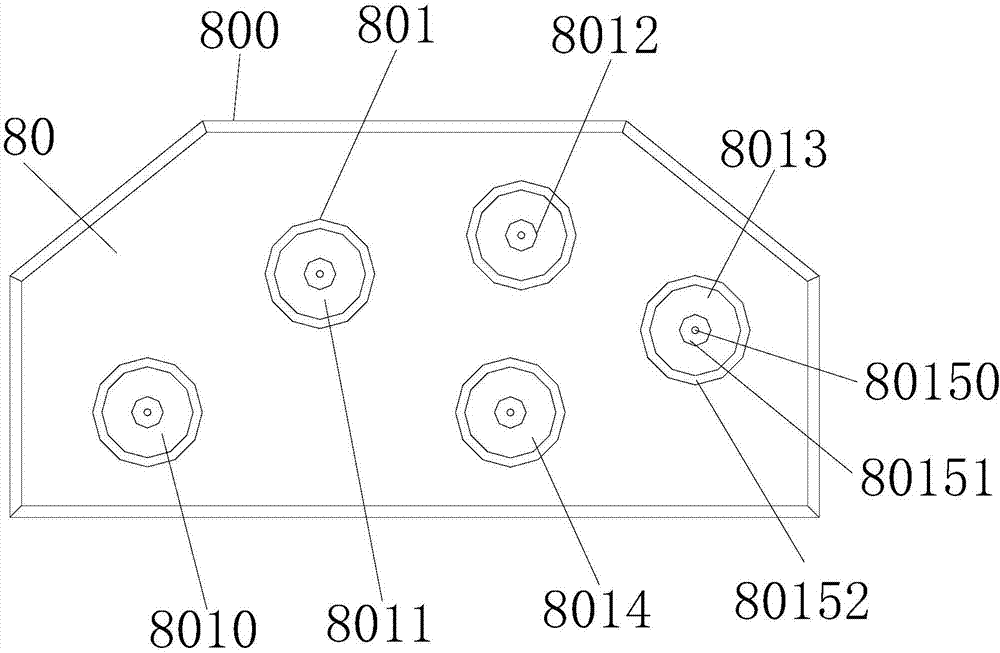

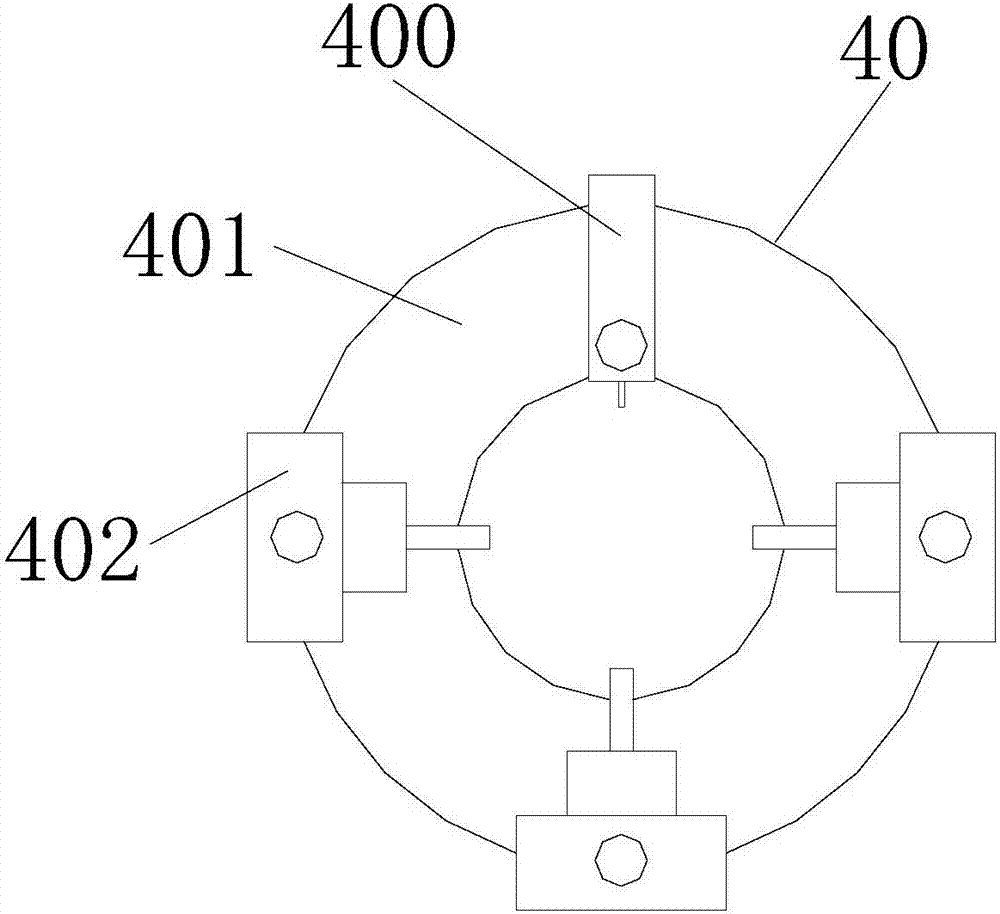

[0028] see Figure 1-Figure 8, the present invention provides a new type of cable stripping machine: its structure includes a control box 1, a control panel 2, an unpacking cabinet door 3, a stripping device 4, an alignment plate 5, a fixed bracket 6, an outlet rod 7, and a wire box 8, The front side of the upper end of the control box 1 is provided with a control panel 2, and the box-opening cabinet door 3 with a rectangular structure is movably connected to the front side of the bottom of the control box 1 through a hinge, and the tail end of the peeling device 4 runs through the box-opening cabinet The door 3 is connected to the inner cavity of the control box 1, the rear side of the alignment plate 5 is movably connected to the front end of the peeling device 4 through the fixed bracket 6, the front end of the outlet rod 7 runs through the fixed bracket 6, and the rear end of the outlet rod 7 is embedded A wire box 8, the wire box 8 is fastened to the front side of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com