Zipper slider inverted inserting machine with slider forward-inserting zipper tape

A technology of zipper tape and head threading machine, which is applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of zipper tape misalignment, zipper reverse threading machine, complex structure of the whole machine, and the failure of the whole machine to work normally, and achieve The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

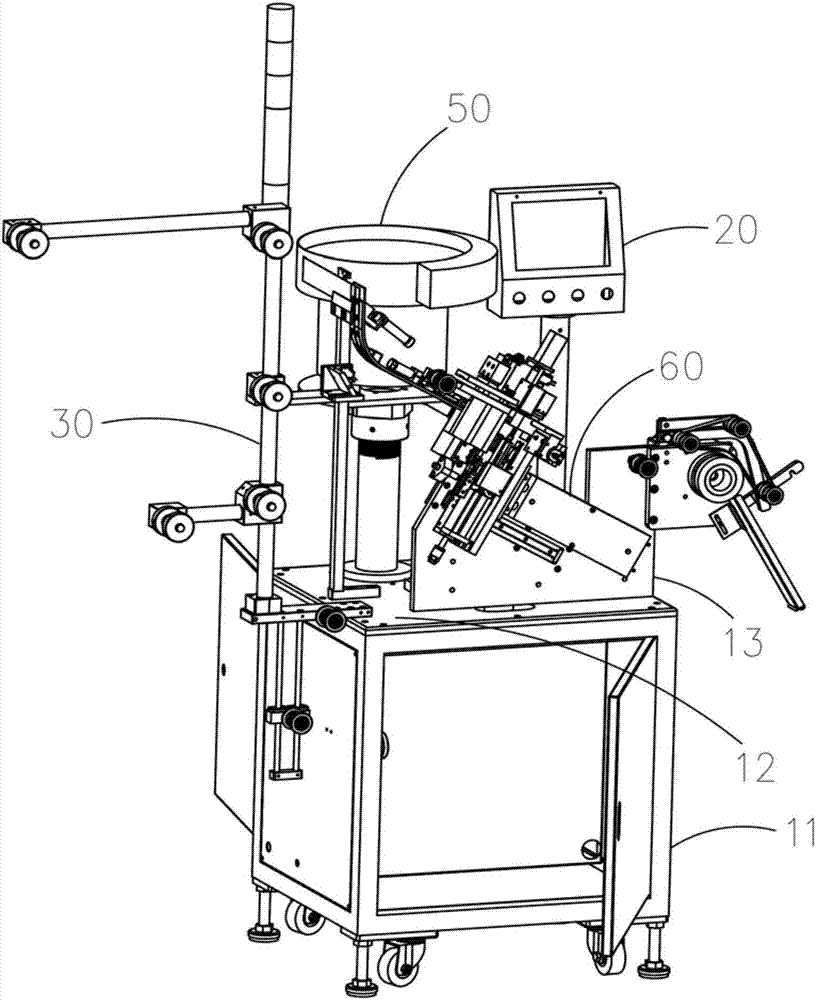

[0039] see figure 1 , the slider of the present embodiment passes through the zipper tape reversely, including a frame 11, a base plate 12 is installed on the frame 11, and a zipper tape action system, a slider action system and a control system 20 are installed on the base plate 12 . The control system 20 is used to control the operation of the zipper tape action system and the slider action system.

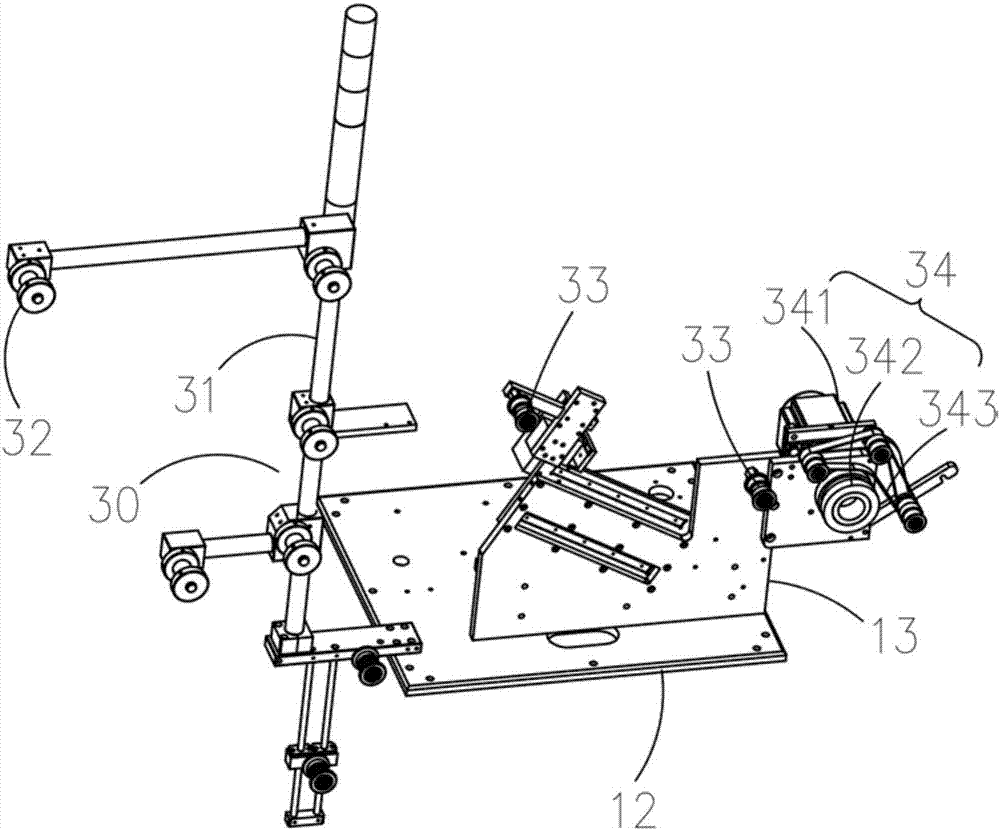

[0040] see figure 2 , there is a wheel bar 31 on the left side of the base plate 12, and several guide wheels 32 are arranged on the wheel bar 31, which are used to guide the zipper tape feeding; There are two guide wheels 33, which are used to adjust and determine the direction of the zipper tape; the right part of the vertical plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com