Bag dust filter type indoor vacuum cleaner

A technology for cleaning machines and vacuuming motors, which is applied to vacuum cleaners, cleaning filter devices, suction filters, etc., which can solve problems such as shortages, and achieve the effects of long use time, low working noise, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

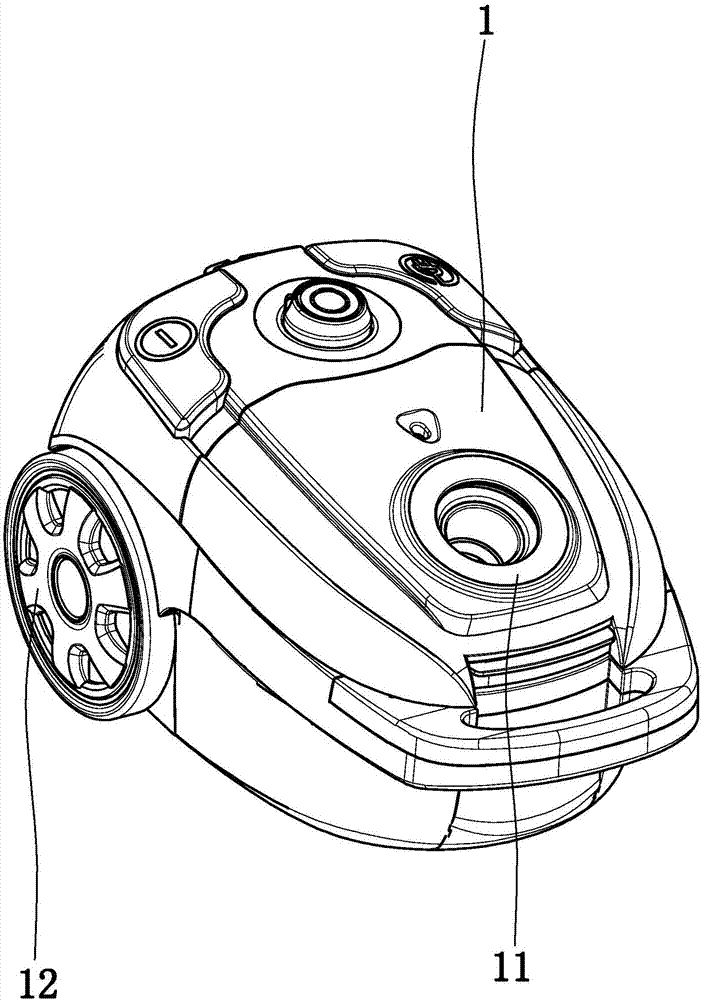

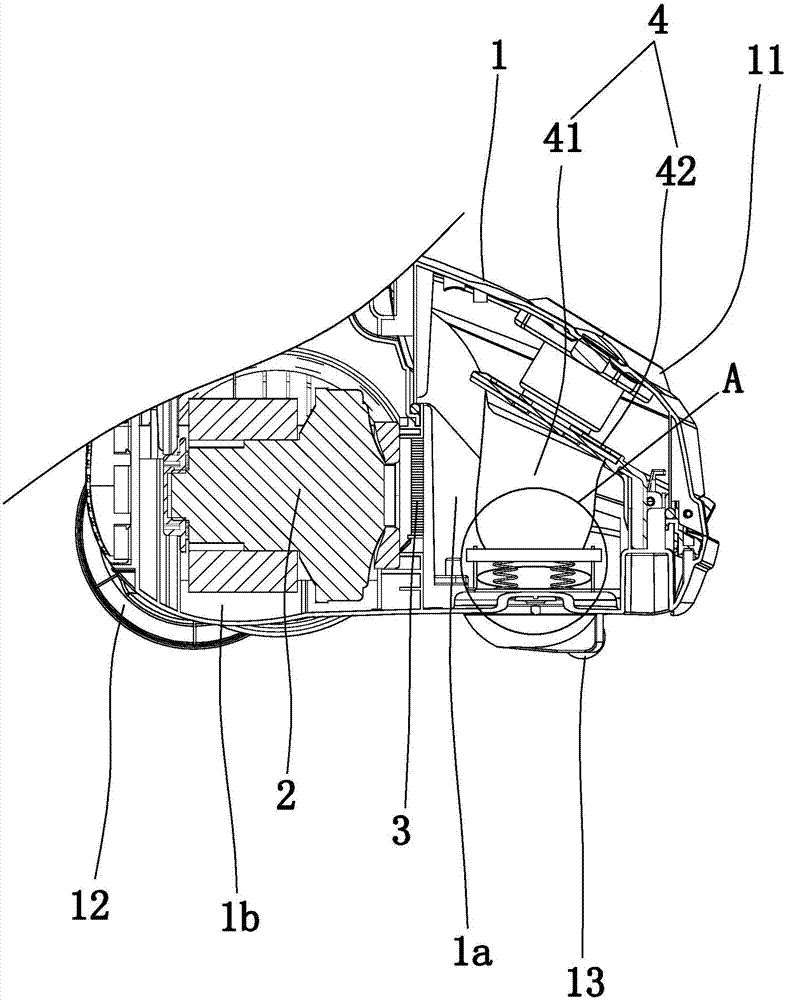

[0029] Embodiment 1: as Figure 1 to Figure 4 In the shown embodiment, a filter dust bag type indoor vacuum cleaning machine includes a main casing 1 and a dust collection motor 2 arranged in the main casing, and also includes

[0030] The vertical partition part arranged in the main casing, the vertical partition part divides the interior of the main casing into a filter cavity 1a and a motor cavity 1b, and the vertical partition part is provided with a fan connected to the air inlet end of the dust collection motor. The inner suction air port is provided with a fine filter 3;

[0031] The dust collection motor is arranged in the motor chamber, the dust collection motor is fixed to the main casing, and the main casing is provided with an outer air outlet connected with the exhaust end of the dust collection motor, an operation port connected with the filter chamber, and a seal for sealing. Hold the opening and closing door of the operation port, and the opening and closing d...

Embodiment 2

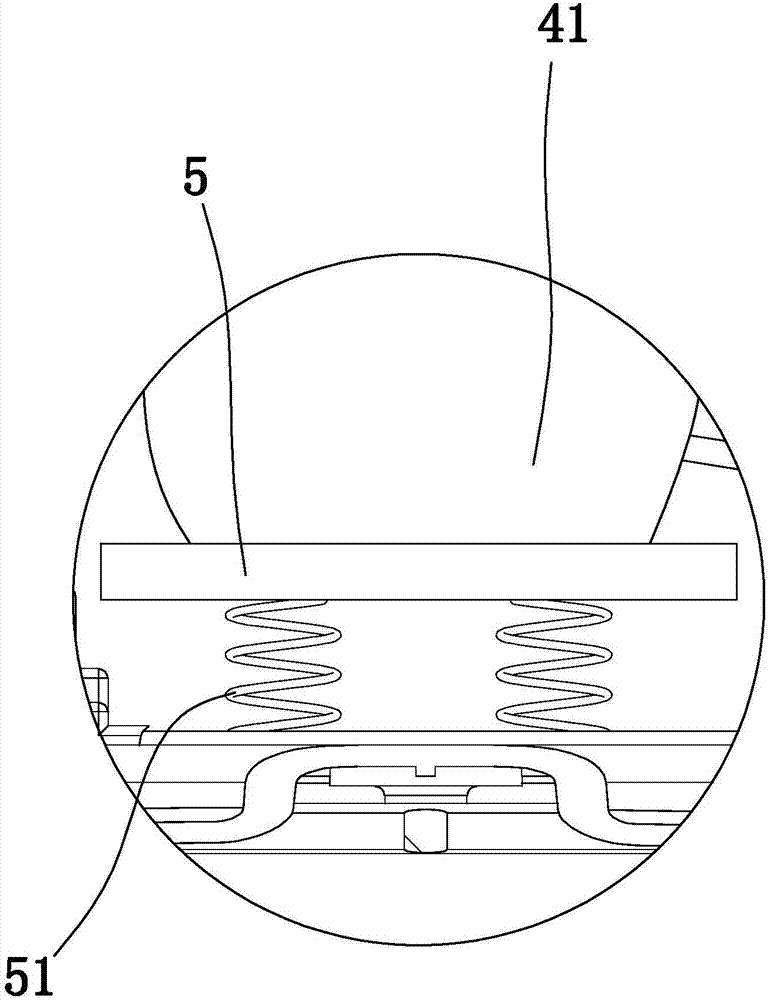

[0041] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 5 to Figure 6 As shown in , the motor cavity is provided with at least one vertical guide rod 52, the vertical guide rod passes through the support plate, the support plate and the vertical guide rod are slidably matched, the vertical guide rod slides in a vertical direction, and the support spring axis is vertical. The vertical guide bar can guide the support plate, which can improve the stability of the support plate in the moving process.

[0042] Described fine strainer comprises exoskeleton ring 31, inner skeleton ring 32 and the annular network body 33 that is arranged between outer skeleton ring and inner skeleton ring, is provided with fixed clutch friction disk 71 on the rotating shaft of dust-collecting motor, fine filter There is a drive shaft 72 arranged horizontally on the net, the drive shaft passes through the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com