Intelligent paper feeding method of paper shredder and paper shredder with intelligent automatic paper feeding function

An automatic paper feeding and shredder technology, applied in grain processing, etc., can solve the problems of low paper feeding speed and shredding efficiency, and non-adjustable paper feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] shredder intelligent paper feeding method, figure 1 shown in 9, including the following steps,

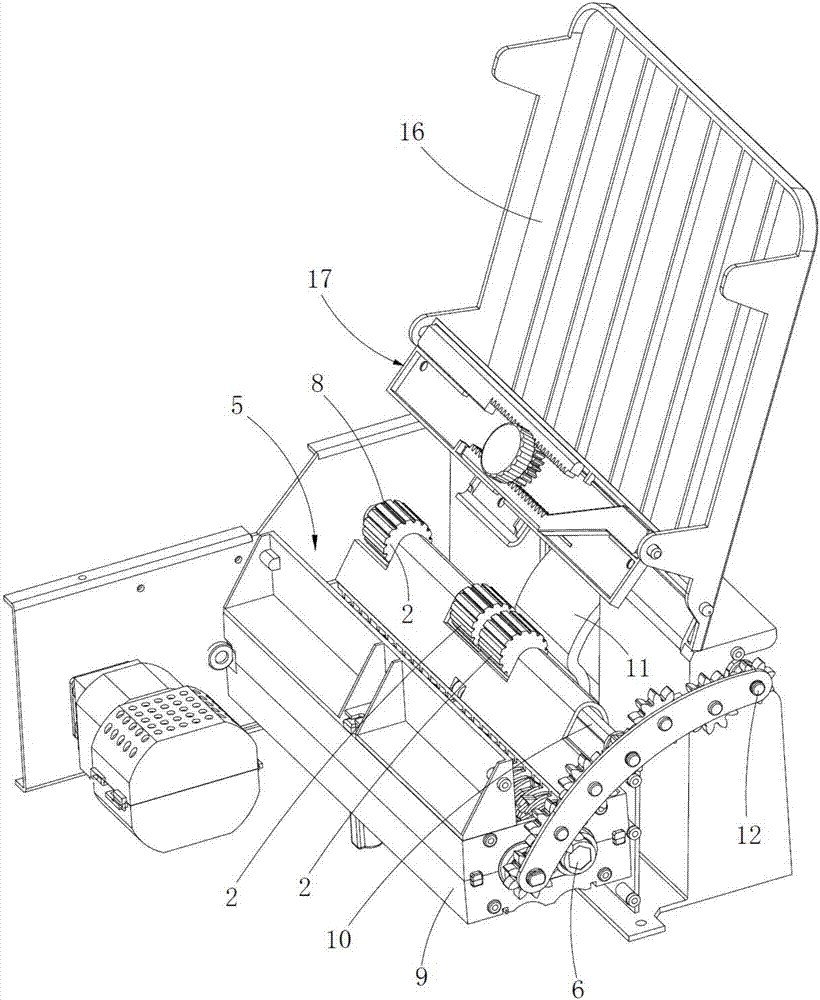

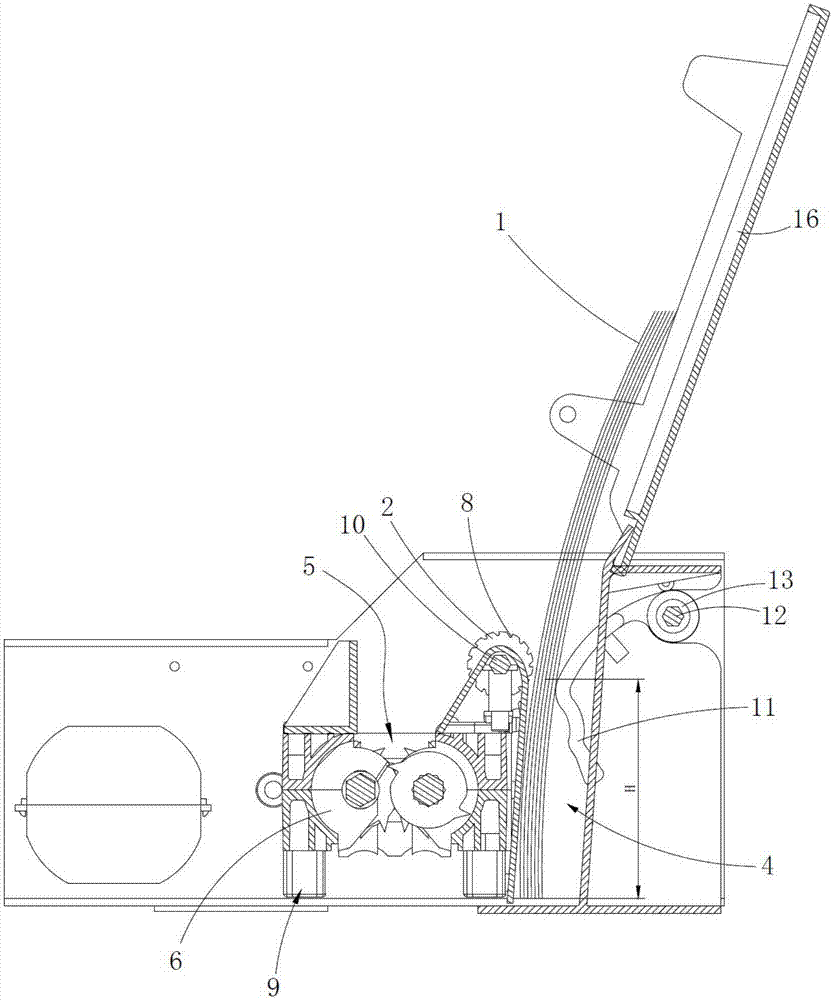

[0071] 1) Paper unloading step, put the piles of paper to be shredded in the paper unloading area of the paper unloading mechanism and form a paper pile, insert the paper pile from the outside of the paper roll device and make the lower end of the paper pile exceed the distance set by the paper roll device H, image 3 As shown, the paper 1 to be shredded and the automatic paper feeding channel 5 are respectively located on both sides of the winding device. The paper roll device selects the paper roll set or the paper roll 2, inserts the lower end of the paper pile into the paper insertion chamber 4 or the lift pallet 3 located outside the paper roll 2, and makes the paper insert the bottom of the chamber 4 or the lift pallet The plate 3 is lower than the set height of the paper reel 2, by adjusting the bottom of the paper insertion chamber 4 or the relative position of t...

Embodiment 2

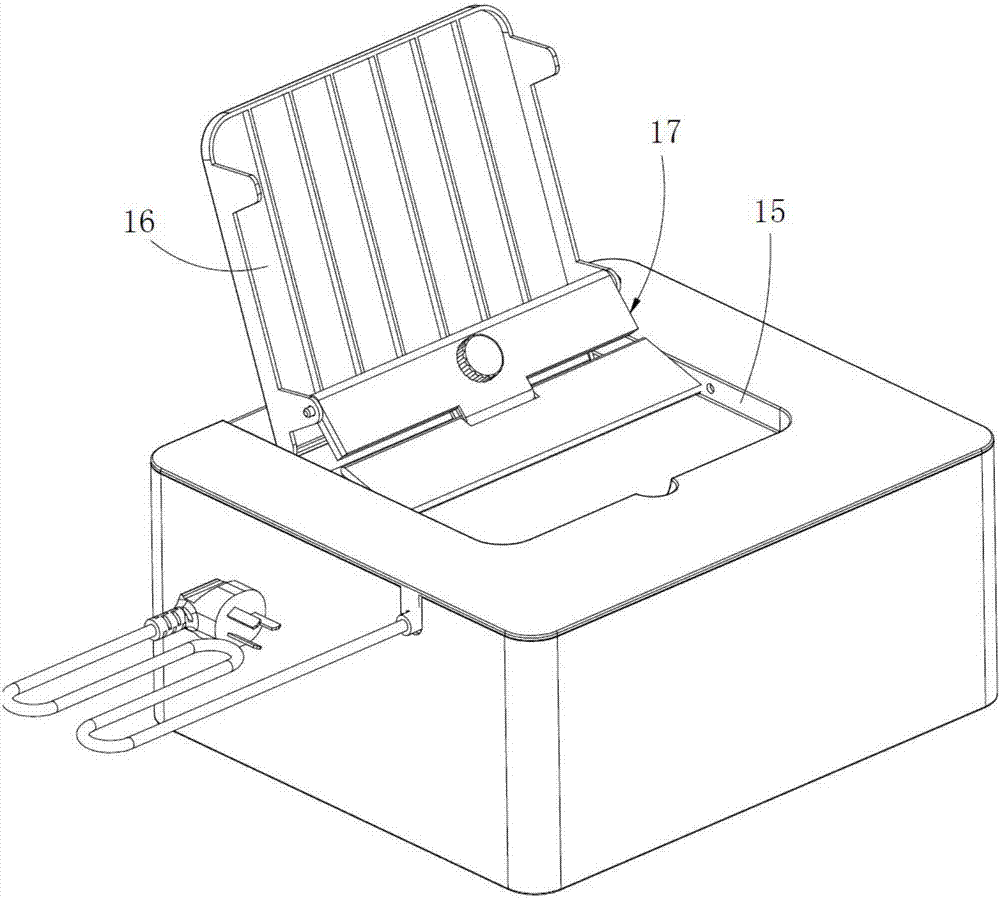

[0097] Intelligent paper shredder with automatic feeding, Figures 1 to 10 As shown, it includes a shredder head, a shredder motor, a shredder cutter 6 and a control circuit. The shredder head is provided with an automatic paper feed port, and the automatic paper feed port is provided with an automatic paper feed channel 5, a paper roll device and In the paper release mechanism, the shredder cutter 6 is arranged in or below the automatic paper feeding channel 5, and the shredder motor is driven to connect the shredder cutter 6. The paper discharge mechanism is provided with a paper release area for placing the paper 1 to be shredded. A paper winding motor is installed, and the paper winding motor drives and connects the paper winding device;

[0098] The paper shredder is equipped with a detection device, which is used to detect the number / thickness of paper entering the automatic paper feeding channel 5 or the voltage / current of the shredder motor, and transmit a detection va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com