Installing support welding clamp

A technology for installing brackets and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inconvenient loading and unloading, unreasonable fixture design, and poor quality and accuracy of finished parts after welding. No problems such as guarantee, so as to achieve the effect of convenient loading and unloading and avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

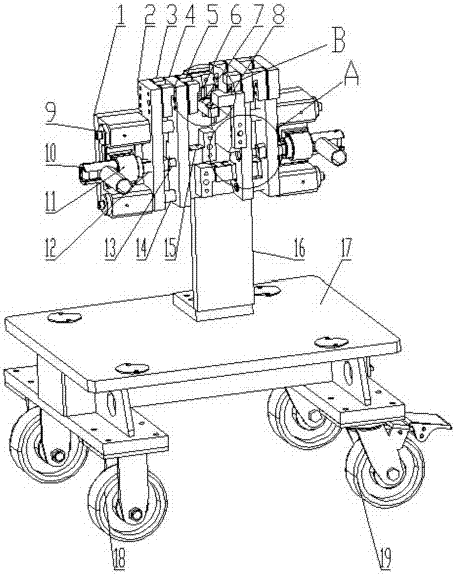

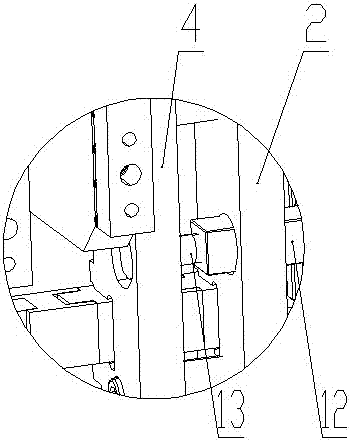

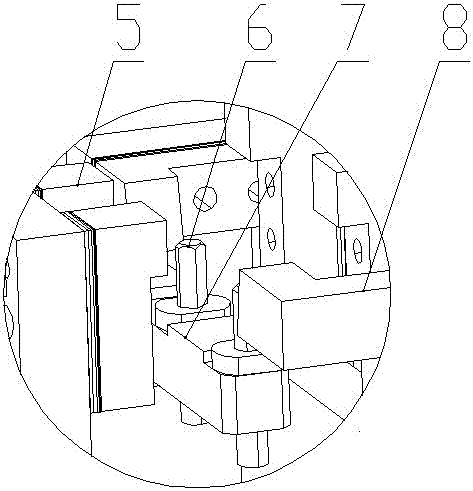

[0016] see figure 1 , figure 2 , image 3 , a mounting bracket welding fixture, including a clamping mechanism; characterized in that: the clamping mechanism is symmetrically arranged on both sides of the template 1, and the clamping mechanism includes a pressing block 5, a sleeve 12, a screw 13, a hand cylinder 9, handle 10, the first end of described screw rod 13 is fixed on the middle part of briquetting block fixing plate 4, and described screw rod 13 is threadedly connected with casing 12, and described casing 12 is fixed on one end of handle 10, and described handle 10 The middle part passes through the axle sleeve 11, and the front end of the hand-push cylinder 9 is provided with a guide rod 14, and the guide rod 14 moves horizontally along the center hole of the hand-push cylinder 9, and the end of the guide rod 14 is in contact with the press The side portion of the block fixing plate 4 is fixedly connected, and the briquetting block 5 is fixed on the top of the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com