Welding model structure capable of being processed serially and using method of welding model structure

A kind of mold and series of technology, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of cumbersome work and low efficiency, and achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

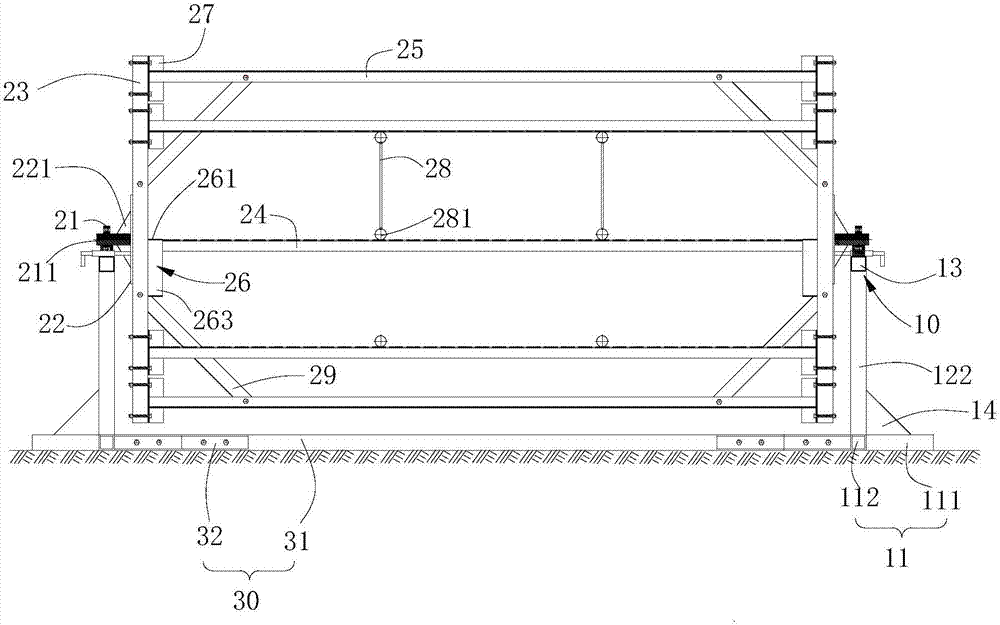

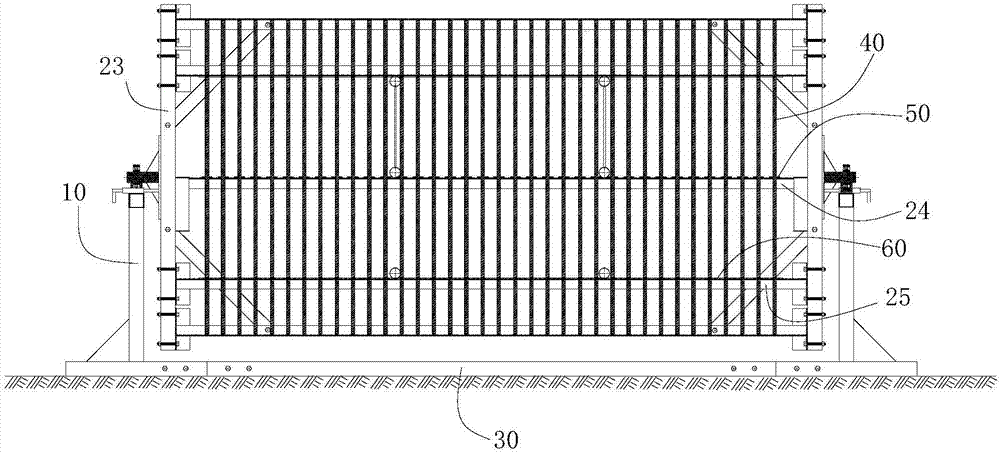

[0037] see Figure 1 to Figure 10 , the present invention provides a serially processable welded mold structure and its use method, which includes two support structures 10 and two rotational positioning structures 20 . in:

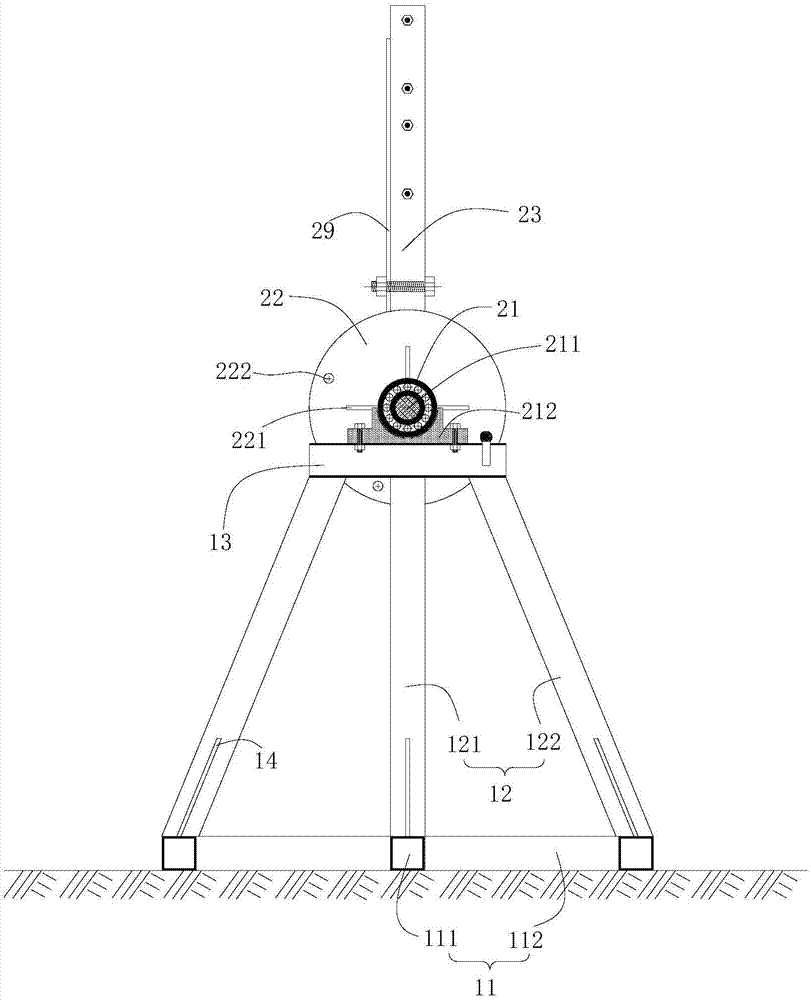

[0038] like figure 1 , image 3 , Figure 4 and Figure 5 As shown, the two bracket structures 10 include a bracket base 11 , a bracket support member 12 and a bracket beam 13 , the bracket support member 12 is arranged on the bracket base 11 , and the bracket beam 13 is arranged on the bracket support member 12 . The bracket supporting member 12 comprises a bracket vertical bar 121 and two bracket slanting bars 122, one end of the bracket vertical bar 121 is connected to the middle part of the bracket base 11, the other end of the bracket vertical bar 121 is connected to the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com