A rare earth-doped optical fiber preform and its preparation method

An optical fiber preform and rare earth doping technology, which is applied in glass manufacturing equipment, glass fiber products, manufacturing tools, etc., can solve problems such as large differences in optical fiber parameters, and achieve the effects of ensuring concentricity, easy drawing, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

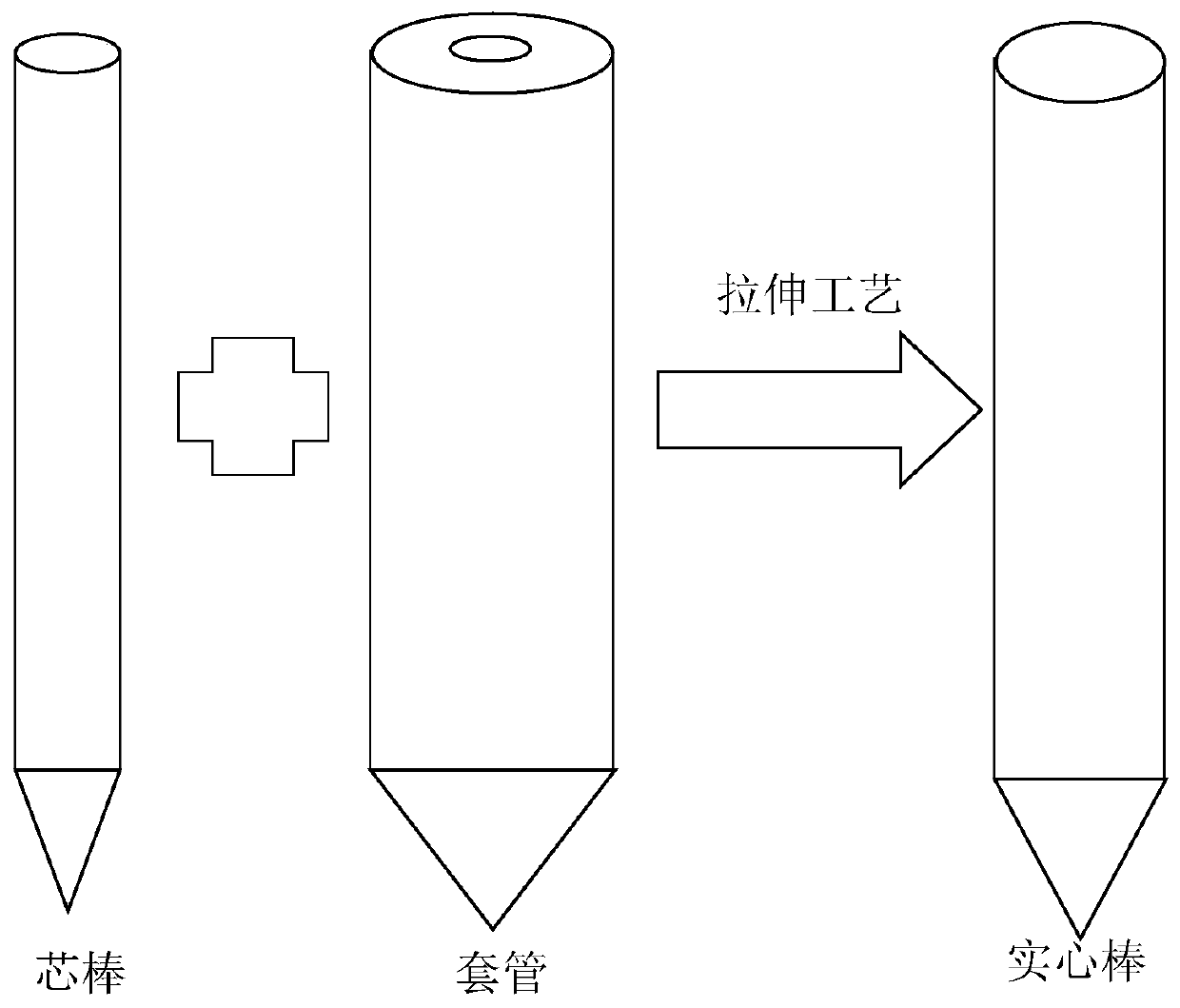

[0039] The preparation method of the rare earth-doped optical fiber preform provided by the present invention comprises the following steps:

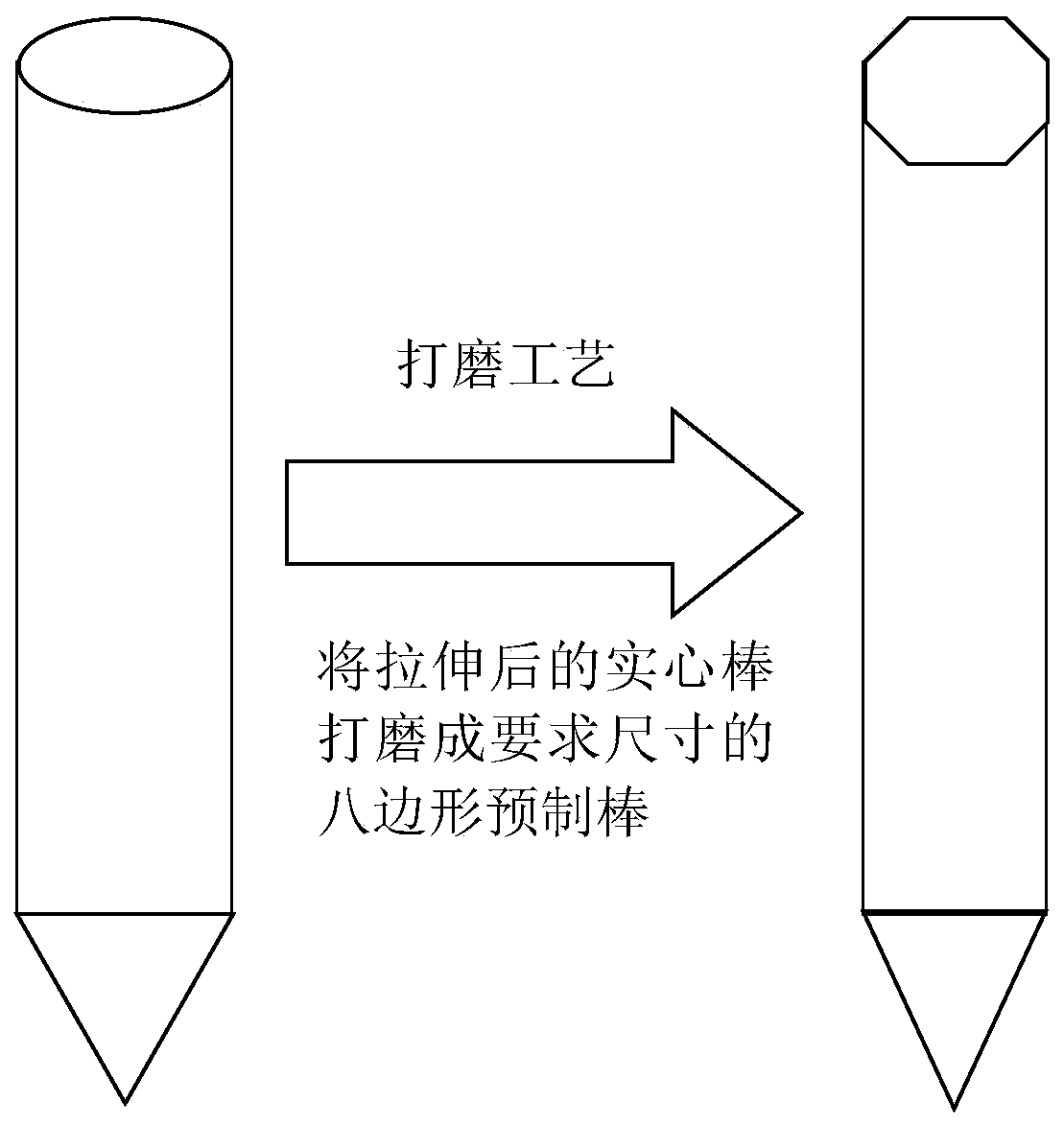

[0040] (1) Wrap the doped core layer with the first quartz cladding material and stretch it until the cross-sectional area ratio matches the cross-sectional area ratio of the second quartz cladding layer, and process its cross section into a predetermined shape to obtain a semi-finished preform;

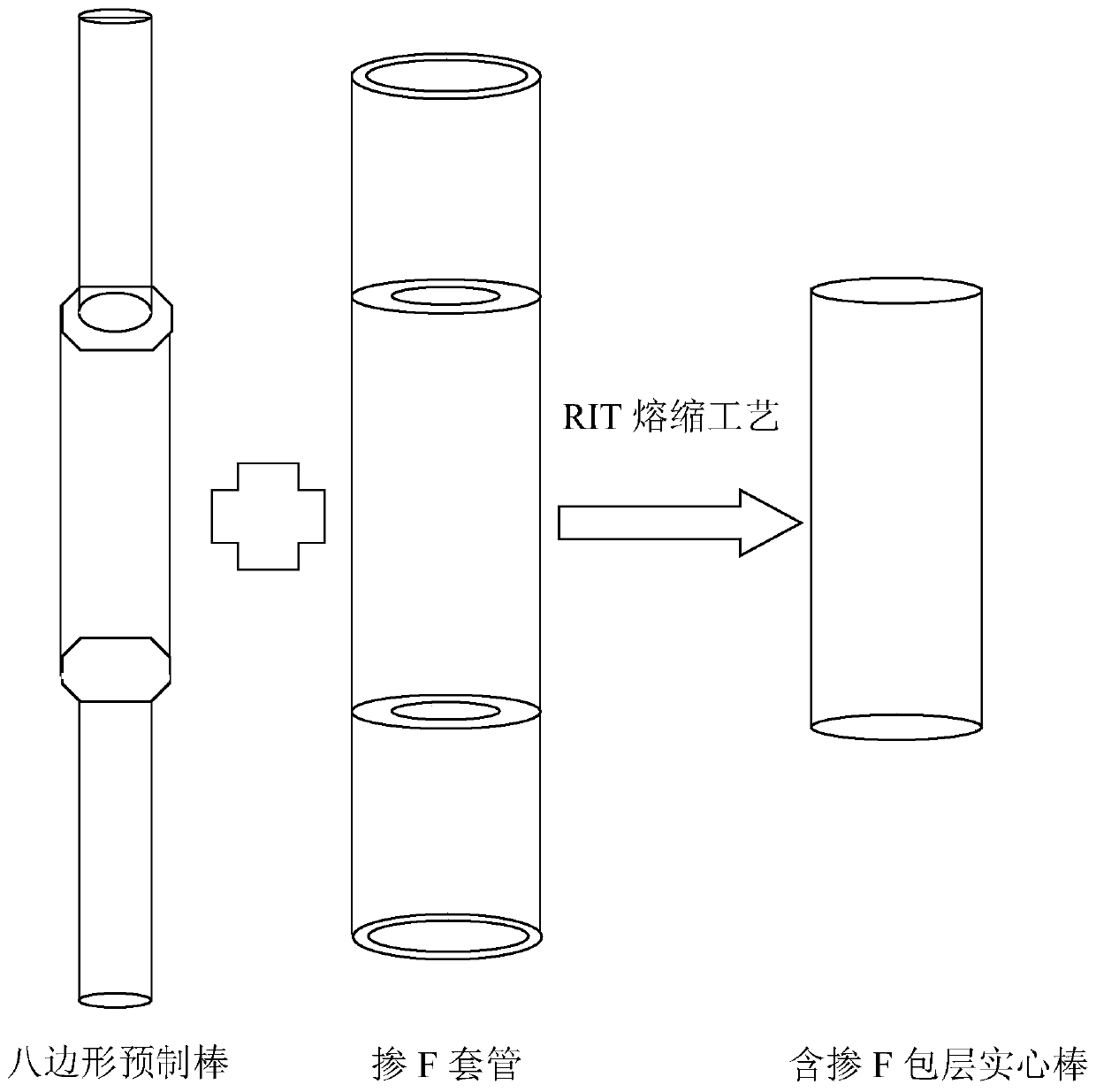

[0041] (2) Wrap the semi-finished preform obtained in step (1) with a second quartz cladding material, and process its cross section into a circle to obtain the doped optical fiber preform.

[0042] It is preferred to adopt the shrinkage burning method, specifically:

[0043] (1) Stretching the doped mandrel and the first quartz-clad sleeve RIT until the cross-sectional area ratio matches the second quartz-clad cross-sectional area ratio, and processing the cross-section into a predetermined shape to obtain a semi-finished preform;

[0044] (2)...

Embodiment 1

[0048] 20 / 350 / 400 type ytterbium-doped triple-clad optical fiber preform and its preparation method

[0049] A rare earth-doped optical fiber preform, including a doped core layer, a first silica cladding, and a second silica cladding from inside to outside;

[0050] The numerical aperture of the doped core layer relative to the first quartz cladding layer is 0.06, and the radius of the doped core layer is 3.00 mm. The core doping composition is 1.0%wt Yb 2 o 3 , 3.5% wt P 2 o 5 , 3.0% wt Al 2 o 3 , 92.5% wt SiO 2 .

[0051] The first quartz cladding is a pure quartz cladding; the cross-sectional shape is a regular octagon. The diameter ratio of the first quartz cladding layer and doped core layer (such as Figure 4 a 2 :a 1 ) is 17.5:1 (the cross-sectional area ratio of the first quartz cladding layer and the doped core layer is 322:1).

[0052] The numerical aperture of described second quartz cladding relative to the first quartz cladding is 0.22, and its diamet...

Embodiment 2

[0062] A kind of ytterbium-doped triple-clad optical fiber preform and its preparation method

[0063] A rare earth-doped optical fiber preform, including a doped core layer, a first silica cladding, and a second silica cladding from inside to outside;

[0064] The numerical aperture of the doped core layer relative to the first quartz cladding layer is 0.2, and the radius of the doped core layer is 6.00 mm. The core doping composition is 1.0%wt Yb 2 o 3 , 3.5% wt P 2 o 5 , 6.2% wt Al 2 o 3 .

[0065] The first quartz cladding is a pure quartz cladding; the cross-sectional shape is a regular hexagon with a radius of 7.8 mm, and the radius of the first quartz cladding refers to half the distance between two parallel opposite sides of the hexagon.

[0066] The numerical aperture of the second quartz cladding relative to the first quartz cladding is 0.12; the second quartz cladding is a fluorine-doped quartz layer, and the mass percentage of fluorine doping is 1.18%. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com