RF steel plastic composite strengthened winding pipe

A steel-plastic composite and winding pipe technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as cracking and low rigidity of plastic-steel wound steel pipes, and achieve reduced impact, good rigidity of the pipe body, and increased rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

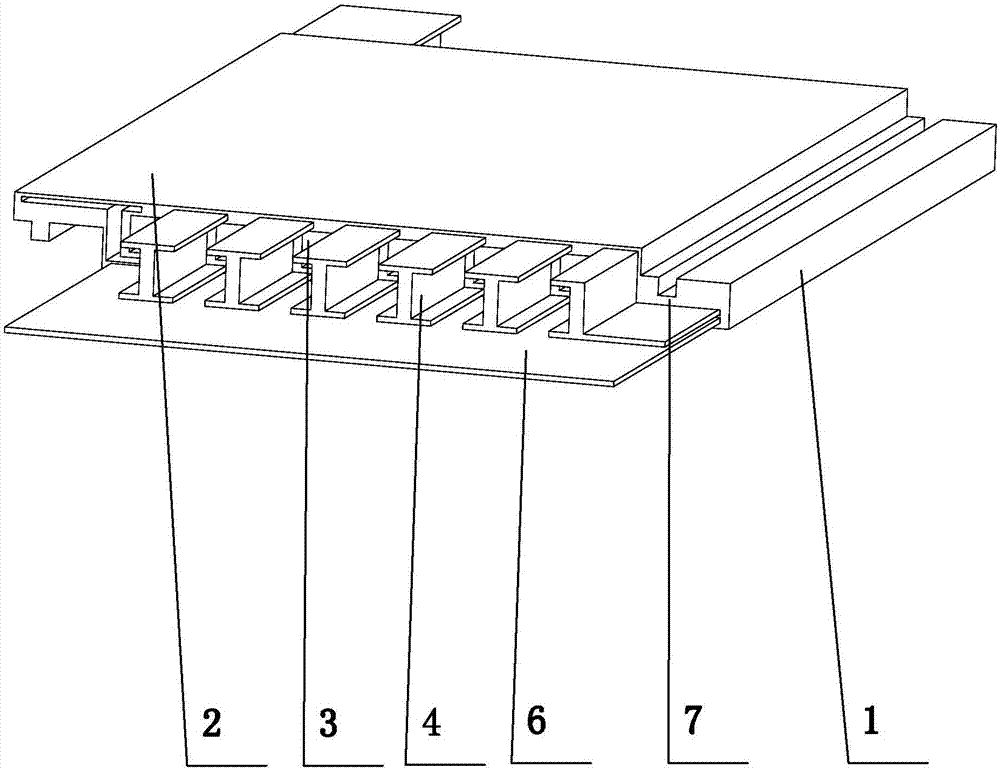

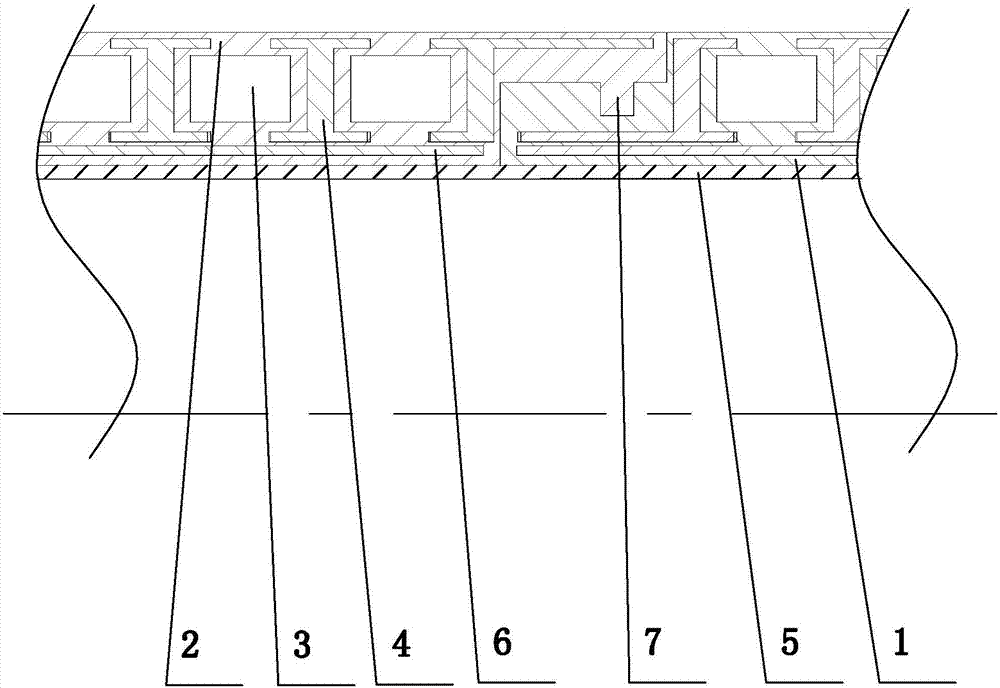

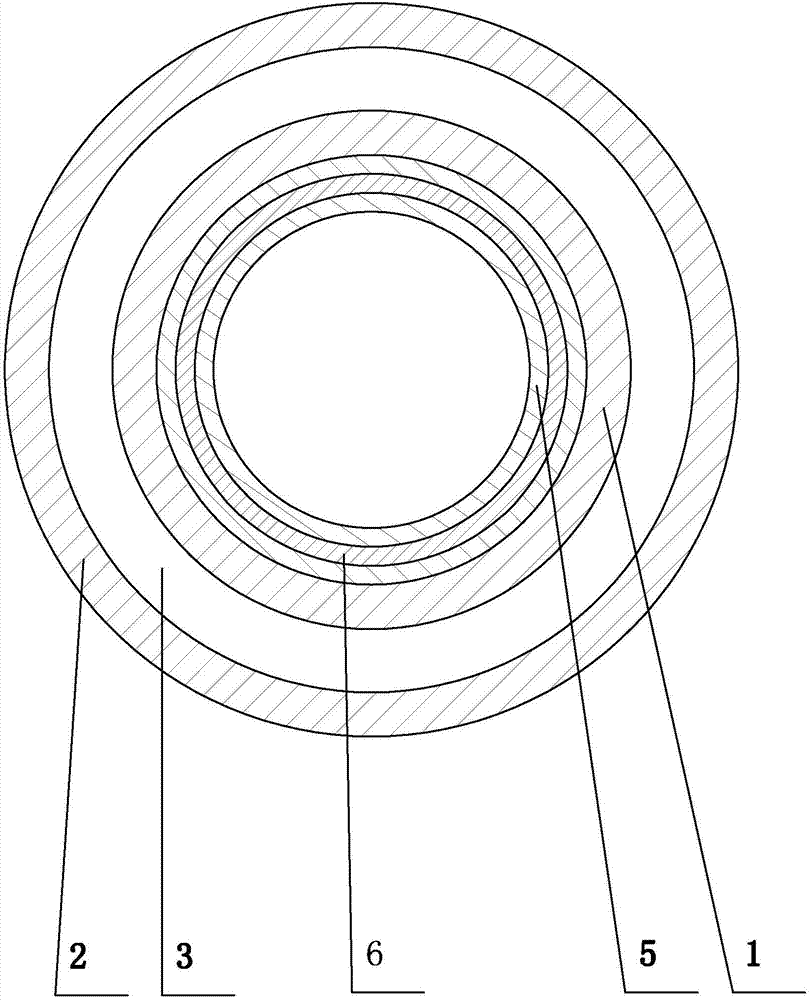

[0023] RF steel-plastic composite reinforced winding pipe, the pipe body is formed by spiral winding of steel-plastic composite tape, the main body of the tape is made of RF polyethylene material, the inner layer 1 and the outer layer 2, the inner layer 1 and the outer layer 2 The airtight cavities 3 distributed at equal intervals are formed between them, the vertical cavity wall and the inner and outer layers form an I-shaped structure, and a steel strip 4 with an I-shaped cross section is set in the I-shaped structure, as shown in the attached figure 1 , 2 shown.

[0024] Both sides of the strip are stepped male-female joints. When the strip is wound spirally, the male-female joints are occluded and bonded to form a whole. The occlusal surfaces corresponding to the joints are provided with corresponding mortise joint struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com