Volume pipe type multiphase flow metering device

A metering device, multiphase flow technology, applied in the direction of volume flow ratio measurement, measurement device, volume/mass flow generated by mechanical effects, etc., can solve the problems of low measurement accuracy, small measurement range, and inability to adapt to production changes in oil wells, etc. Achieve the effect of closed metering structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

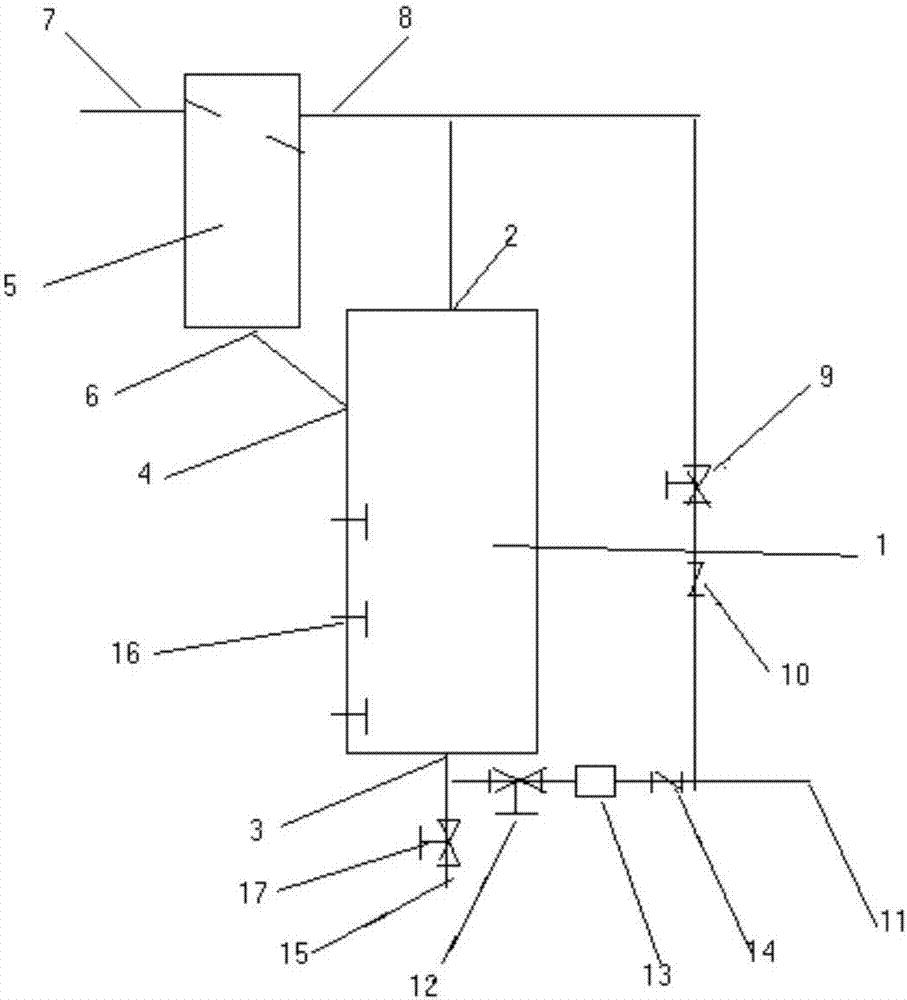

[0025] A volumetric tube type multiphase flow metering device, see figure 1 , the metering device comprises a metering tank 1, the top of the metering tank 1 is provided with a tank body gas outlet 2, the bottom of the metering tank 1 is provided with a tank body outlet 3, the top of the metering tank 1 is provided with a tank body liquid outlet 4, and the tank body liquid outlet 4 is connected with the pipeline liquid junction 6 of the metering pipeline 5, the upper part of the metering pipeline 5 is provided with a pipeline inlet 7 and a pipeline gas junction 8, the pipeline gas junction 8 is connected with the tank gas junction 2, and the pipeline gas junction 8 is connected with the tank gas junction. The junction 2 is connected to the gas path control valve 9, the first check valve 10, the gas flow meter and the metering outlet 11 in sequence, and the tank outlet 3 and the metering outlet 11 pass through the liquid path control valve 12, the water content meter 13 and the ...

Embodiment 2

[0032] A volumetric tube type multiphase flow metering device is similar to Embodiment 1, except that the number of capacitive liquid level switches 16 is three.

[0033] Preferably, the capacitive liquid level switches 16 are evenly distributed from top to bottom.

[0034] Preferably, the capacitive liquid level switch 16 includes two polar plates respectively.

[0035] Preferably, the distance between two pole plates of each capacitive liquid level switch 16 is at least 10 cm. In this way, it prevents the oil from sticking the two plates together to adapt to the high-viscosity medium. It adopts the capacitive wide plate liquid level switch, which can solve the problem that the high-viscosity medium sticks the floating ball and cannot be measured in the past.

Embodiment 3

[0037] A volumetric tube type multiphase flow metering device, which is similar to Embodiment 2, except that the water content meter 13 is a tube type water content analyzer.

[0038] Preferably, the moisture meter 13 is connected with a controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com