Crystal grain screening device

A screening device and grain technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inconvenience in use and difficulty in sorting grains, and achieve convenient use, easy homing, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

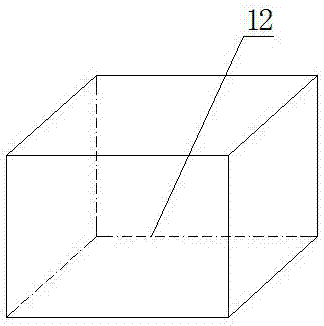

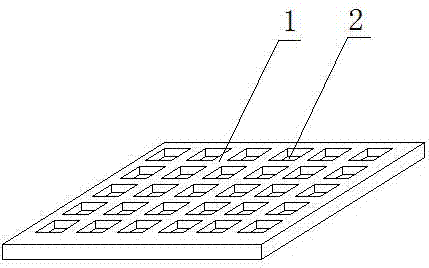

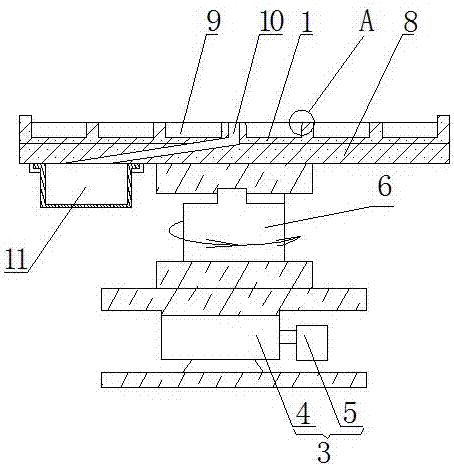

[0020] Such as figure 1 , 2 , 3, 4, and 5, a grain screening device includes a grain arrangement mold 1, the grain arrangement mold has an array of grain placement holes 2, and the placement holes cooperate with the arranged grains; There is a vibration device 3 below the grain arrangement mold, and the vibration device is formed by installing an eccentric wheel 5 on the motor shaft head by a motor 4. It is characterized in that: there is also a vibration device between the vibration device and the grain arrangement mold. A rotating device 6, said rotating device can make the crystal grain arrangement mold rotate 360 degrees horizontally.

[0021] The rotating device is a motor that can rotate the grain arrangement mold.

[0022] When the device of the present invention is in use, the crystal grains are tilted to the left and right on the grain arrangement mold, and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com