Vertical multi-auger mixer with blades

A mixer and vertical technology, applied in the field of vertical multi-auger mixers, can solve the problems affecting the nutritional supplement of dairy cows, waste of feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

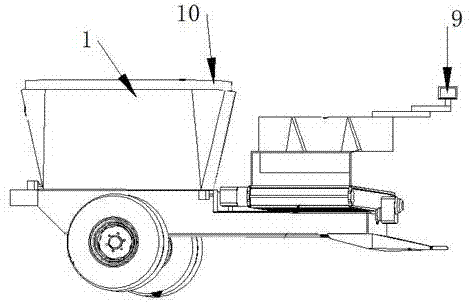

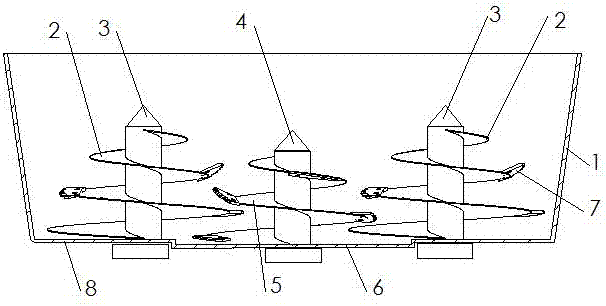

[0019] Such as image 3 A vertical multi-auger mixer with blades is shown, comprising a material box with a bottom wall and a continuous side wall 1, a frame supporting the material box, and a weight measuring device installed between the frame and the material box.

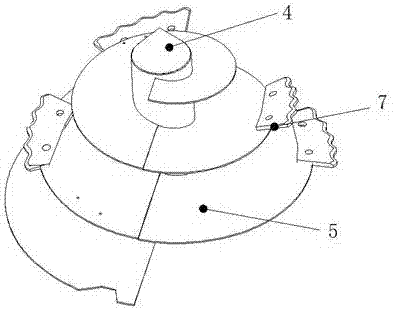

[0020] The bottom wall includes a main bottom wall 6 and two secondary bottom walls 8 located on both sides of the main bottom wall 6 and higher than the main bottom wall 6 , the main bottom wall 6 and the secondary bottom walls 8 are arranged horizontally. The main bottom wall 6 is equipped with a vertical main transmission shaft 4 through a bearing, and the vertical main transmission shaft 4 is driven to rotate by the driving device, and the vertical secondary transmission shaft 3 is installed on the secondary bottom wall 8 through a bearing. The power transmission shaft 3 is also connected with a driving device that drives its rotation. The driving device in this embodiment can be an electric motor or other ty...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the main bottom wall in this embodiment is located at one end of the bottom wall, and the two secondary bottom walls are located at one side of the main bottom wall, and the heights are increased successively, so that the forage grass that is crushed can be drawn from one end. Gradually transfer to the other end to prevent the main screw blade from bringing the feed to the secondary bottom wall during discharge, improving the discharge efficiency.

[0029] During use, the vertical main transmission shaft 4 and the vertical secondary transmission shaft 3 can be selected to rotate in opposite directions to improve the cutting efficiency of forage grass. The feed lifted by the helical blades moves outward from the upper part of the main transmission shaft and the vertical secondary transmission shaft to the side wall of the feed box, and then moves downwards towards the bottom wall. When the feed reaches the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com