A high-efficiency double-head cable cutting saw

A cutting saw and high-efficiency technology, which is applied in the field of high-efficiency double-headed cable cutting saws, can solve the problems of low cutting efficiency, potential safety hazards, and lack of good support devices, and achieve high cutting efficiency, reduce potential safety hazards, and improve cutting efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

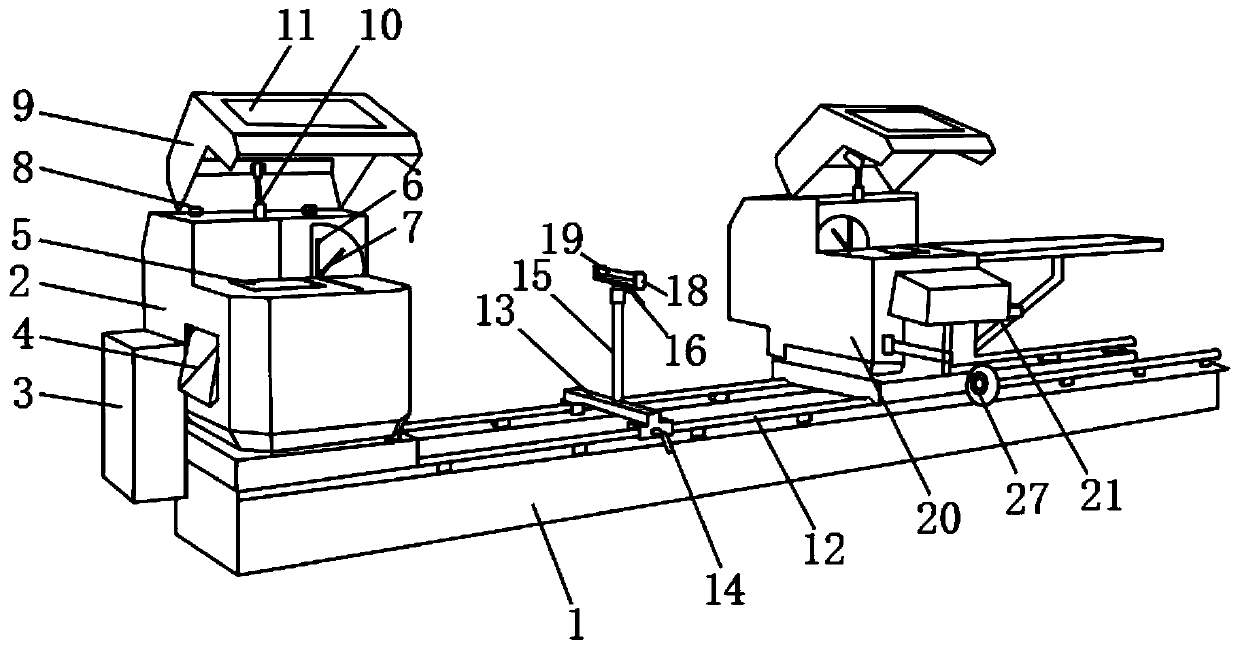

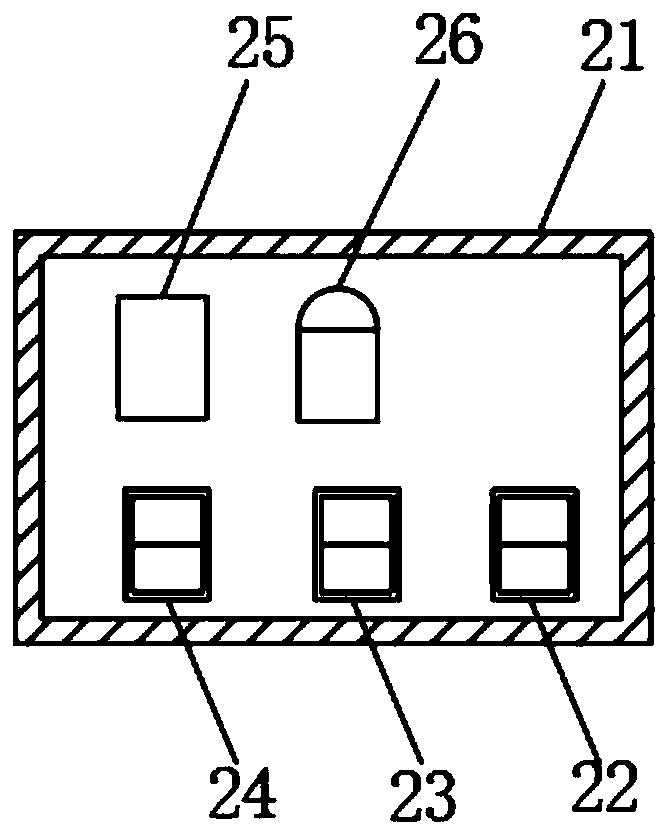

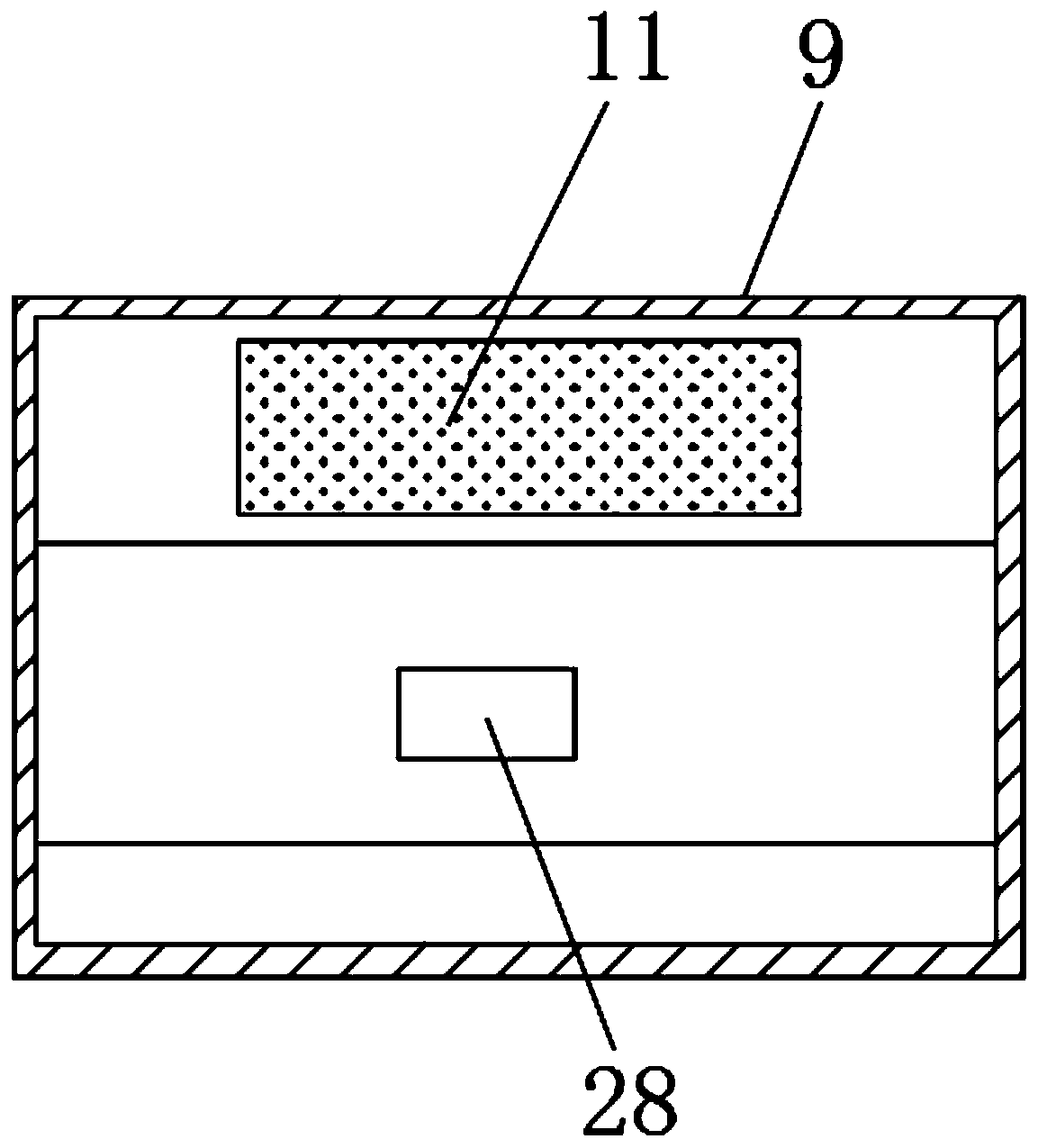

[0022] see Figure 1-5 , the present invention provides a technical solution: a high-efficiency double-headed cable cutting saw, including a base 1, a first cabinet 2, an electric control box 3, a waste outlet 4, a waste inlet 5, a right-angle cutter groove 6, forty Five-degree cutter groove 7, hinge 8, protective cover 9, hydraulic rod 10, viewing window 11, guide rail 12, fixed frame 13, first fastening knob 14, first support rod 15, second fastening knob 16, the first Two support rods 17, support 18, rotating shaft 19, second cabinet 20, control panel 21, power switch 22, hydraulic pump switch 23, cutting saw switch 24, PLC controller 25, alarm 26, pulley 27, hum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap