Gradient gray filter coating device and coating method thereof

A filter and plating technology used in the field of optical filters to achieve the effect of improving linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

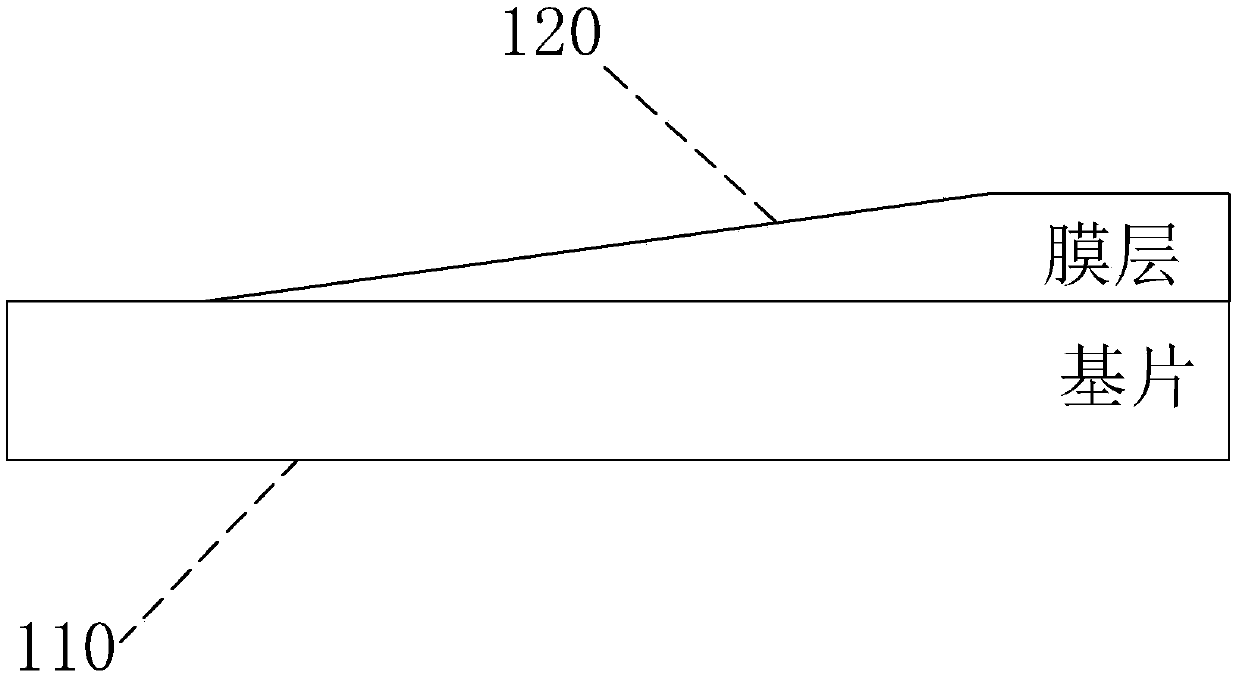

[0026] Gradient gray filter is a kind of commonly used physical filter, also known as GND filter. It is mainly used to balance the light ratio, so that the dark part and highlight part of the picture are reasonably exposed. It is suitable for the environment with large light ratio, such as for shooting daylight Scenes at dusk. The gradient gray filter structure includes a substrate 110 and a film layer 120. The film layer 120 contains a black material. In order to achieve a gradient effect, the thickness of the film layer 120 must show a gradually decreasing trend from one side to the other, so the gradient One side of the gray filter is gray-black in color, and gradually fades to the other side, so that the other side becomes transparent.

[0027] refer to figure 1 , the basic structural diagram of a gradient gray filter of a gradient gray filter coating device of the present invention. figure 1 In the case of single-side plating, the film layer 120 is attached to one surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com