Gradient glass and its preparation method and application

A glass and solution technology, applied in electrical equipment shell/cabinet/drawer, chassis/cabinet/drawer parts, electrical components, etc., can solve problems such as low light transmittance and inability to meet usage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

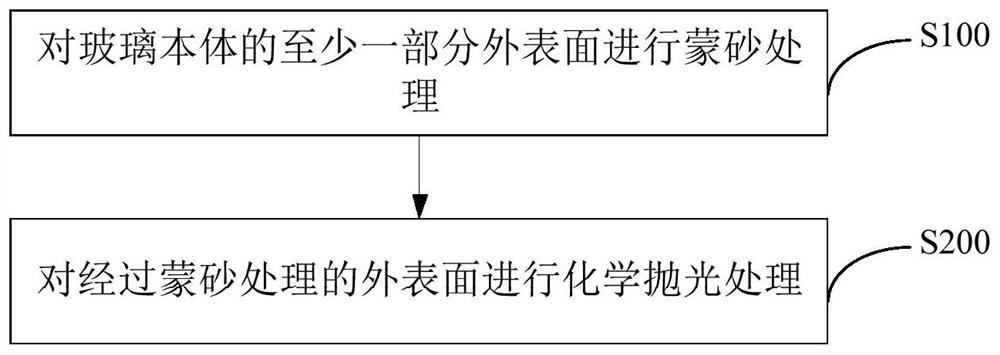

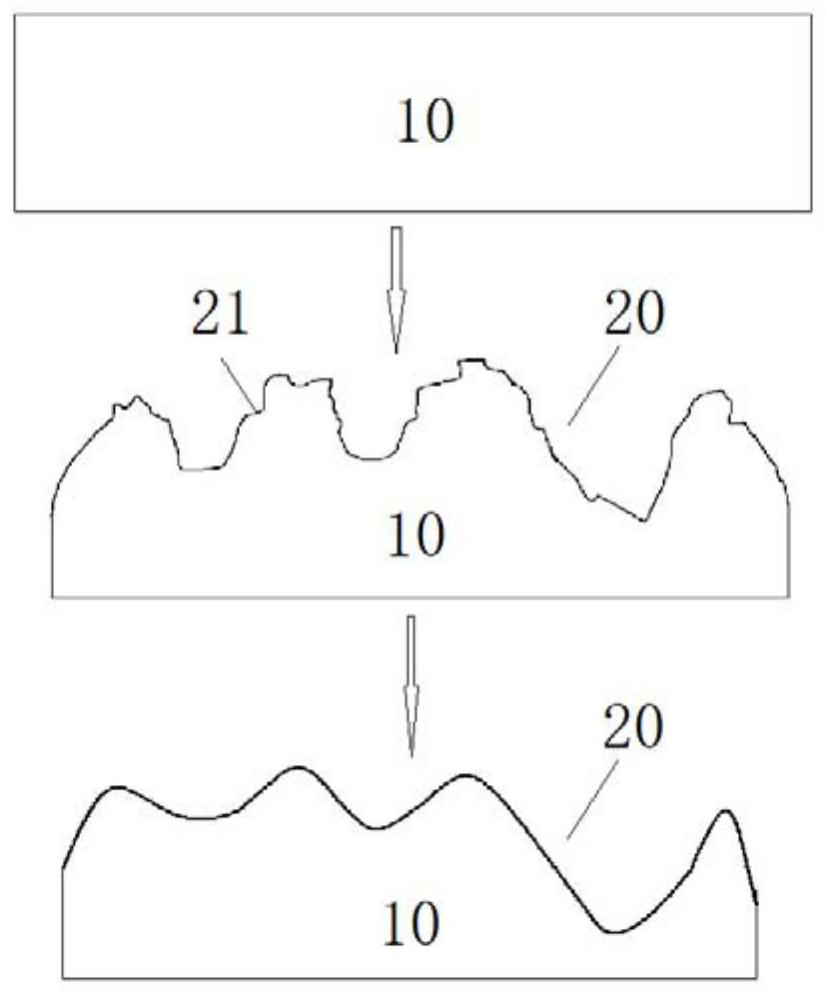

Method used

Image

Examples

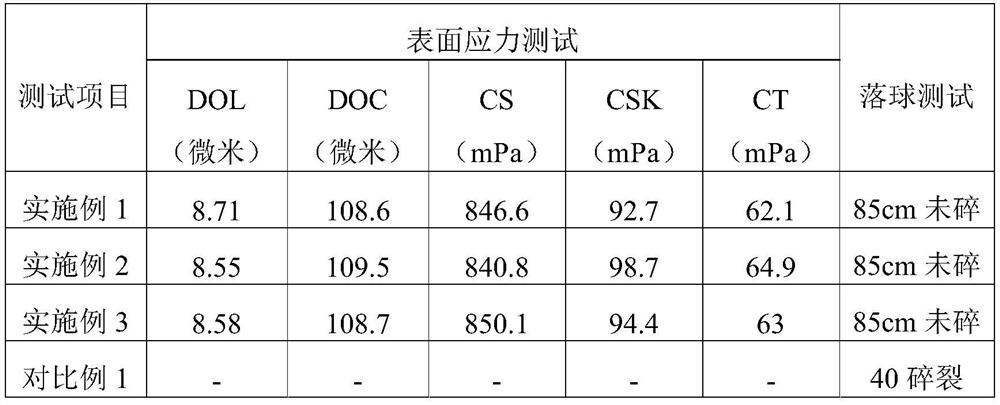

Embodiment 1

[0038] Using aluminosilicate glass, the thickness is 0.6mm, the length is 160mm and the width is 75mm. Clean the glass, cover one side of the glass with acid-resistant ink, fix the A side of the glass, and lower the B side (the other side opposite to the A side) at a speed of 1.2mm / S until the glass is completely immersed in the frosting treatment liquid (ammonium bifluoride mass ratio of 25%, potassium fluoride mass ratio of 5%, and barium sulfate mass ratio of 8% aqueous solution), and then quickly pull out the liquid surface, and then wash with a large amount of water. The surface of the glass forms a gradient frosting effect, the surface roughness RA of the A end is 0.15 microns, and the haze is 35%. The percentage of the ratio of the scattered luminous flux Td at an angle of 2.5° to the luminous flux T2 passing through the gradient glass, the haze test method in this paper is the same), the surface roughness RA of the B-end is 0.35 microns, and the haze is 90%. Fix the B...

Embodiment 2

[0040] Using aluminosilicate glass, the thickness is 0.6mm, the length is 160mm and the width is 75mm. The glass is cleaned, and the whole glass is directly immersed in frosting acid solution (an aqueous solution with a mass ratio of 30% of ammonium bifluoride, 5% of potassium fluoride, and 8% of barium sulfate) to uniformly corrode the glass, and the surface roughness RA of the glass is 0.4 micron, 99% haze effect, wash and dry for later use. Fix the A side of the glass, and drop the B side (the other side opposite to the A side) at a speed of 0.12mm / S until the glass is completely immersed in the chemical polishing acid solution (aqueous solution containing 5wt% hydrofluoric acid and 2wt% sulfuric acid) , and then quickly pull out the liquid surface, and then wash with plenty of water. The surface roughness RA of end A is 0.36 micron, and the haze is 90%, and the surface roughness of end B is 0.1 micron, and the haze is 15%. Achieve uniform gradient etching on the entire s...

Embodiment 3

[0042] Using aluminosilicate glass, the thickness is 0.6mm, the length is 160mm, and the width is 75mm. The glass is cleaned, one side of the glass is covered with acid-resistant ink, the A side of the glass is fixed, and the B side (the other side opposite to the A side) is lowered at a speed of 1.2mm / S until the glass is completely immersed in the frosting treatment solution (ammonium bifluoride 30% by mass, 5% by mass of potassium fluoride, and 8% by mass of barium sulfate in an aqueous solution), and then quickly pulled out of the liquid surface, and then cleaned with a large amount of water. The surface of the glass forms a gradient frosting effect, the surface roughness RA of the A-end is 0.15 microns, and the haze is 35%, and the surface roughness RA of the B-end is 0.35 microns, and the haze is 90%. Then immerse the glass as a whole in a chemical polishing acid solution (containing 5wt% hydrofluoric acid and 2wt% sulfuric acid aqueous solution) for 10 minutes, the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com