Thermal shell fabric and preparation method thereof

A production method and fabric technology, applied in chemical instruments and methods, knitting, synthetic resin layered products, etc., can solve problems such as excessive weight, excessive thickness of thermal insulation fabrics, inconvenient movement, etc. The effect of excellent, excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

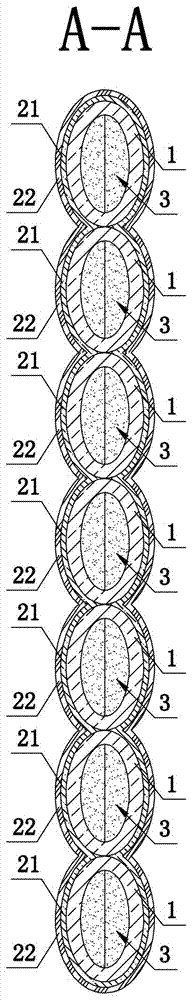

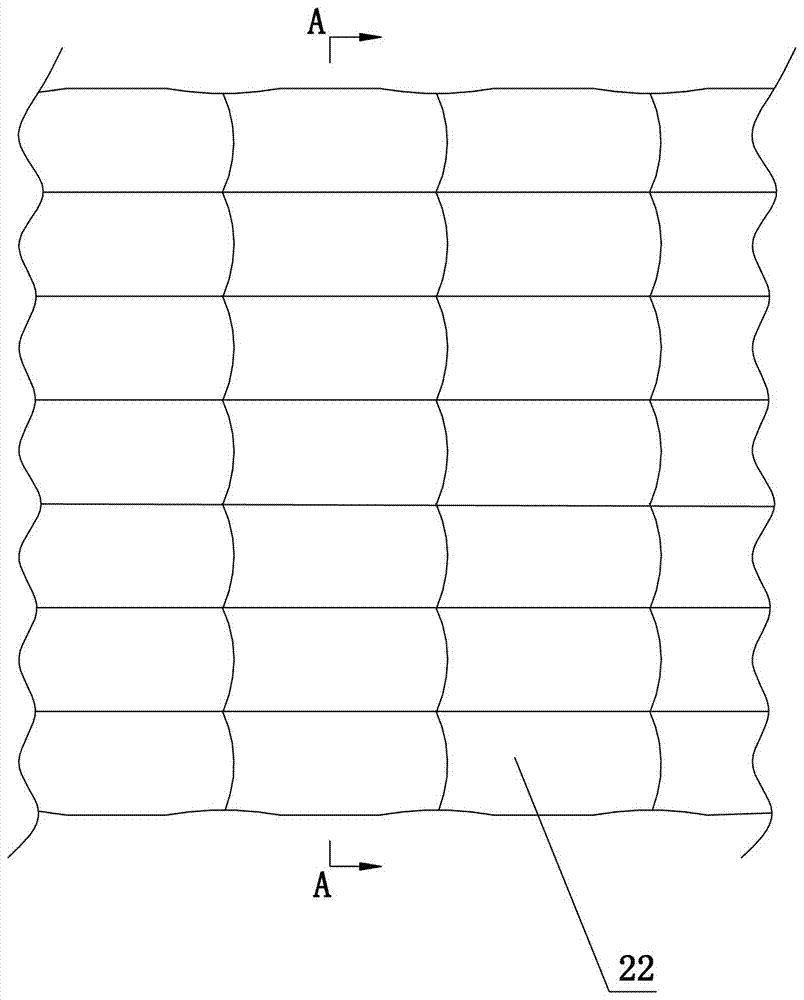

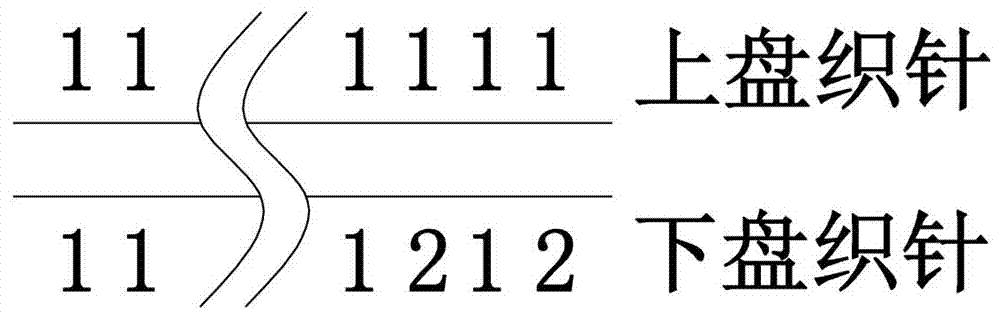

[0031] refer to figure 1 , figure 2 , a thermal fabric, comprising a woven layer 1 and a surface layer, the surface layer is arranged on the outer edge of the woven layer 1 . The woven layer 1 is composed of a plurality of adjacent hollow tubular bodies. Each of the above-mentioned tubular bodies is provided with a plurality of the above-mentioned accommodating cavities, and the accommodating cavities in the same tubular body are arranged adjacent to each other along the extending direction of the tubular body. The accommodating cavity is filled with airgel particles 3 and arranged. The above-mentioned weaving layer 1 is a structure formed by weaving 75D / 36F hollow polyester yarns through 30-inch 28-pin 84-way double-sided circular weft machine. The thickness of the woven layer 1 located at the edge of the accommodating cavity is 1.5 mm to 2.5 mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com