Base fabric having core-abutting member, and method for manufacturing same

A manufacturing method and gray cloth technology, which is applied in the field of gray cloth materials with adjacent materials with core materials, can solve the problems of inability to ensure air permeability, inability to join finished products, etc., and achieve easy installation position accuracy, beautiful surface of finished products, and fast bonding firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

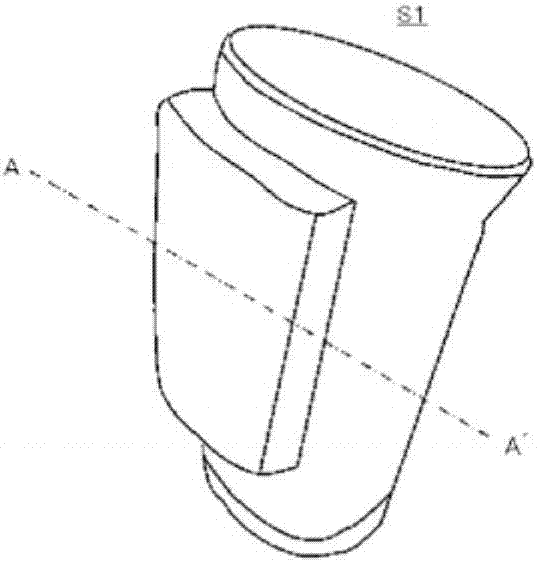

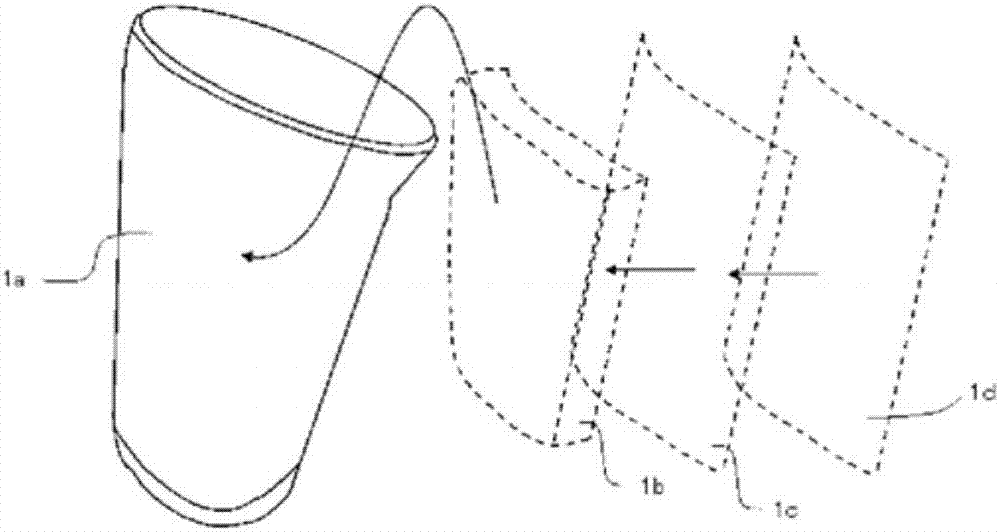

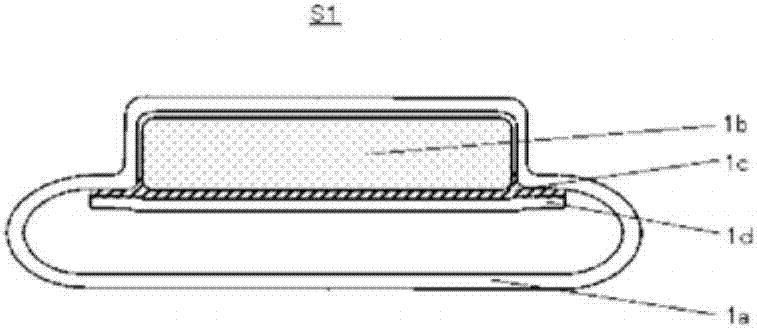

[0057] figure 1 It is a perspective view showing the protector S1 of the first embodiment of the present invention, figure 2 It is a perspective view showing the parts used. image 3 It is A-A sectional drawing of the supporter S1.

[0058] The protector S1 of this embodiment is described as a cylindrical protector with a cushioning material worn by athletes (volleyball players, basketball players, etc.) to protect elbow joints, knee joints, etc. from impact.

[0059] The protector S1 is composed of a fabric material 1a consisting of the protector main body, a core material 1b consisting of a cushioning material, an adjoining material 1d consisting of cloth having a size and shape just enough to cover the cushioning material, and having the same size and shape as the adjoining material 1d The adhesive film 1c constitutes; it is manufactured by sandwiching the core material 1b at a set position of the fabric material 1a with the adjacent material 1d.

[0060] The gray cloth...

no. 2 Embodiment approach

[0077] The second embodiment of the present invention adopts Figure 6 The manufacturing process is implemented.

[0078] Prepare the adjacent material 1d of pre-banded core material 1b, and go to the concave mold K ( Figure 4 ) Insert the adjacent material 1d of the pre-taped core material 1b, and insert it into the recess. Set the gray fabric material 1a and the adhesive film 1c corresponding to the bonding area on the bottom pad, and remove the mold K in which the above-mentioned adjacent material 1d and core material 1b have been embedded, and heat it with a hot plate H from the bottom pad side. , the adhesive film 1c is melted to form the bonding between the fabric material 1a and the adjacent material 1d. After cooling, it was taken out from the mold K, whereby the protector S2 was produced.

[0079] Although the example given in this embodiment is to use the adjoining material 1d pre-attached with the core material 1b, and the core material is inserted into the midd...

no. 3 Embodiment approach

[0082] The third embodiment of the present invention adopts Figure 7 The manufacturing process is implemented.

[0083]An adhesive film 1c and an adhesion preventing cloth 1e having the same size and shape as the adjacent material 1d are prepared and dummy bonded to the adjacent material 1d. The so-called anti-bonding cloth here refers to the cloth attached to the preset non-bonding place. For example, when the core material 1b part is not bonded, the cloth that matches the shape of the core material 1b is virtually bonded to the adhesive film 1c. superior. As for the pasting position of the anti-adhesion cloth 1e, since it is not fixed on the core part, it can be pasted on a free position on the adhesive film according to the design requirements, or it can be pasted on multiple positions.

[0084] To the mold K ( Figure 4 ), the gray cloth material 1a, the core material 1b, and the adjacent material 1d to which the adhesive film 1c and the anti-adhesion cloth 1e have bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com