Particulate matter adsorption device used for tin-printing can making plant

An adsorption device and particle technology, applied in the installation of electrical equipment, suction nozzles, applications, etc., can solve the problems of high noise, high power consumption, etc., and achieve the effects of easy control, simple operation, and improved cleaning and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

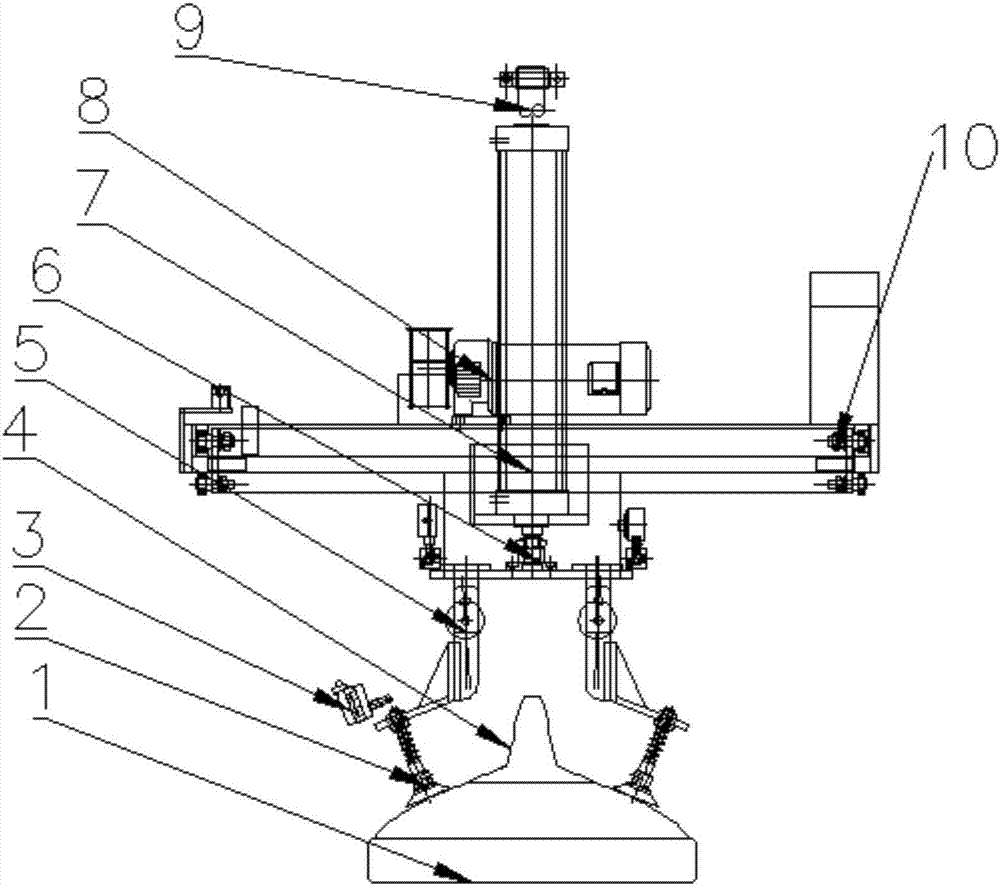

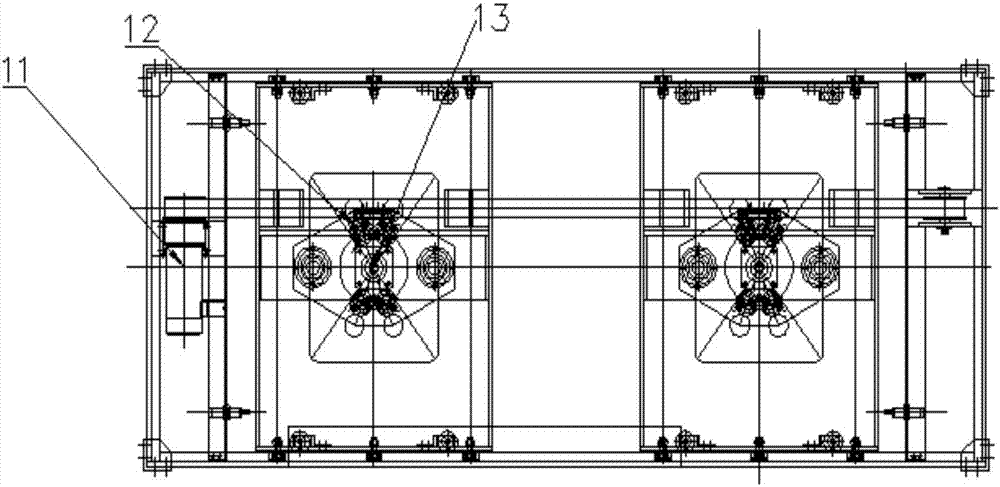

[0016] Such as Figure 1-Figure 2 As shown in the figure, a particle adsorption device for printing iron and can making workshops includes a suction nozzle 1, a dust bag 4, an exhaust fan 7 and a dust collector 11. The suction nozzle 1 can absorb garbage and dust, and the two ends above it are installed There is a movable wall 2, which can flexibly move and absorb dust. A noise reducer 3 is installed on the upper end of the movable wall 2, which can reduce the noise of the equipment. The dust bag 4 is installed on the inner side of the lower end of the noise reducer 3. Both ends above the bag 4 are equipped with an electric brush 5, which can scrub the garbage. The upper end of the electric brush 5 is equipped with a throat 6, which can transport garbage dust. The upper end of the throat 6 is connected with the exhaust fan 7, which can carry out The suction sucks the rubbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com