Construction method for feeding module and grate module of garbage incinerator in limited space

A waste incinerator and limited space technology, which is applied in the field of installation and maintenance of large furnace bodies, can solve the problems of inconvenient installation of parts, avoid complex hoisting operations, reduce workload, and facilitate construction period and quality control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated below by specific examples.

[0031] A construction method for a feed module and a grate module of a garbage incinerator in a limited space, including

[0032] Step 1. Installation of feeder support structure and grate support structure:

[0033] Step 1.1. Check and mark the concrete foundation platform to ensure that it meets the installation requirements of the feeding module and the grate module;

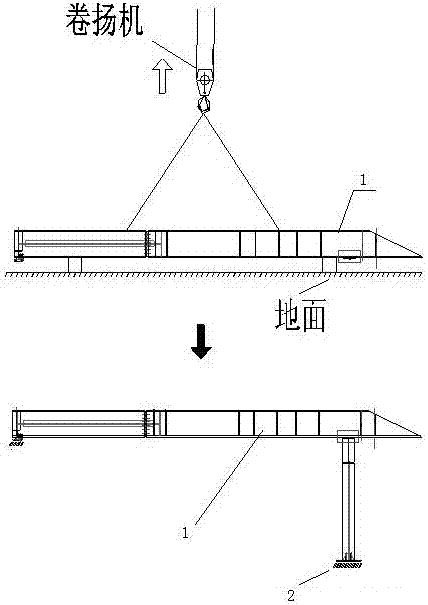

[0034] Such as figure 1 as shown,

[0035] Step 1.2, the lower platform 1 of the feeder support structure is assembled on the side of the concrete foundation platform, and the whole is lifted and installed on the concrete foundation platform 2;

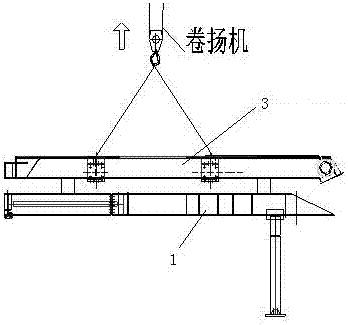

[0036] Such as figure 2 as shown,

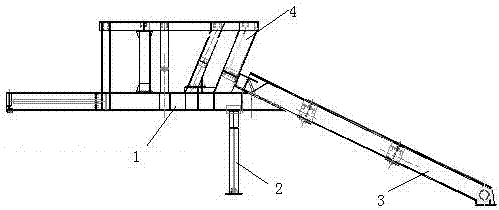

[0037] Step 1.3, take the feeder support structure lower platform 1 as a temporary work platform, and assemble the grate support structure 3 on it,

[0038] Step 1.4, move the grate support structure to the target installation position and temp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap