Feeding device for livestock breeding

A livestock and poultry breeding and breeding technology, which is applied to the field of breeding devices for livestock and poultry breeding, can solve the problems of increasing the risk of food safety problems, instability, and high input costs, reducing the chance of cross-infection of meat ducks, being simple and convenient to use, and reducing ammonia. The effect of gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

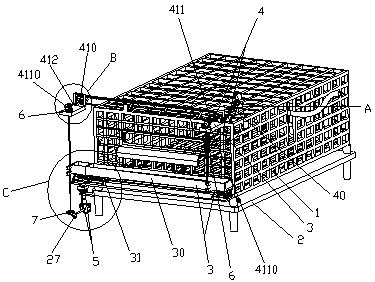

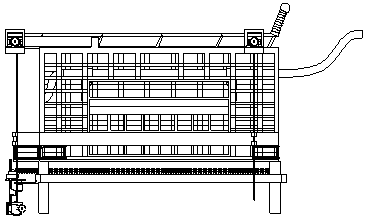

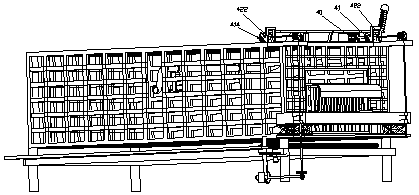

[0030] see Figure 1 to Figure 10 , the present invention is: a breeding device for livestock and poultry breeding, comprising a cage body 1, a dung board 2 arranged below the cage body 1, a trough structure 3 located at the front end of the cage body 1, arranged on the top of the front side of the cage body 1 The power mechanism 4, and the waterline system running through the cage body 1, wherein a cleaning structure 5 for cleaning the feces on the top surface of the manure board 2 is provided on the side of the cage body 1.

[0031] The cleaning structure 5 includes a connecting plate 20 arranged on the dung plate 2, a power motor 21 arranged on the connecting plate 20, a power gear 22 arranged on the power motor 21, and a rotating member 23 abutting against the power gear 22, which is arranged on The cleaning part 24 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com