Full-automatic heating and stirring intelligent emulsifying device for cosmetic production

A technology of heating, stirring and emulsifying devices, which is applied to mixers with rotating stirring devices, mixer accessories, chemical instruments and methods, etc., which can solve the problems of liquid temperature not meeting requirements, economic losses of producers, and prolonging emulsification time. Achieve the effects of low production cost, simple structure, and reduced emulsification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

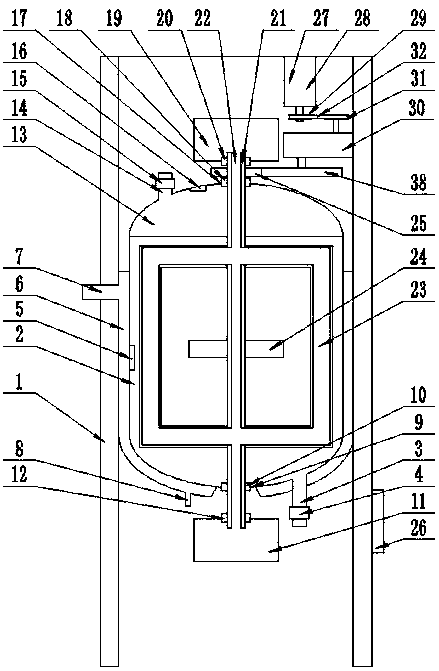

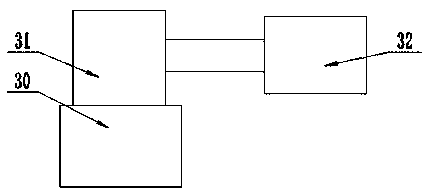

[0018] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a fully automatic heating and stirring intelligent emulsification device for cosmetics production includes a frame 1, the frame 1 is fixedly installed on the ground, the frame 1 is provided with a reactor device, and the reactor device is located at The reaction kettle body 2 fixedly connected to the frame 1 above the frame 1, the liquid outlet pipe 3 fixedly connected to the reaction kettle body 2 on one side of the lower surface of the reaction kettle body 2, the solenoid valve 1 fixedly installed on the liquid outlet pipe 3, The temperature sensor 5 fixedly connected to the reactor body 2 in the reactor body 2, the jacket 6 fixedly connected to the reactor body 2 on the outer surface of the reactor body 2, and fixed to the jacket 6 on the side surface above the jacket 6 The connected outlet pipe 7, the water inlet pipe 8 fixedly connected to the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com