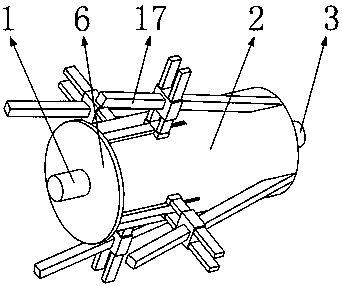

A torque limiter for construction electric drill equipment based on slider

A technology of torque limiter and slider, which is applied in the direction of drilling/drilling equipment, mechanical equipment, metal processing equipment, etc., and can solve problems that affect the normal use of the torque limiter and damage the output shaft of the torque limiter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

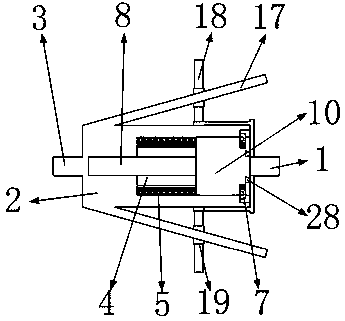

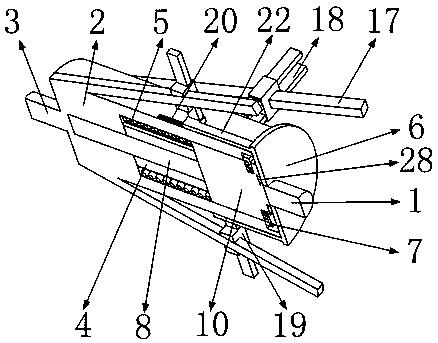

Method used

Image

Examples

specific Embodiment approach

[0039] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: When people are using the electric drill designed by the present invention, the input shaft 1 rotates, and the input shaft 1 drives the driving ring 10 to rotate; because in the initial state, one end of the four limit trigger blocks 7 is located at four The rotation of the driving ring 10 will drive the drive shell 2 to rotate through the four limit trigger blocks 7; the drive shell 2 drives the output shaft 3 to rotate; that is, the electric drill can be used normally. When the drill bit on the electric drill reaches a high speed during use, in order to prevent the drill bit from breaking, the torque on the drill bit needs to be small in this case, that is, the torque of the output shaft 3 on the torque limiter needs to be adjusted to make it change. When the torque limiter designed by the present invention reaches a certain limit, the limit trigger block 7 installed on the drive ring 10 will move under centrifugal act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com