Clamp for lens cutting machine

A cutting machine and lens technology, applied in glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of defective lenses, rework repair, scrapping, etc., and achieve the effect of reducing scratches, reducing defects, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

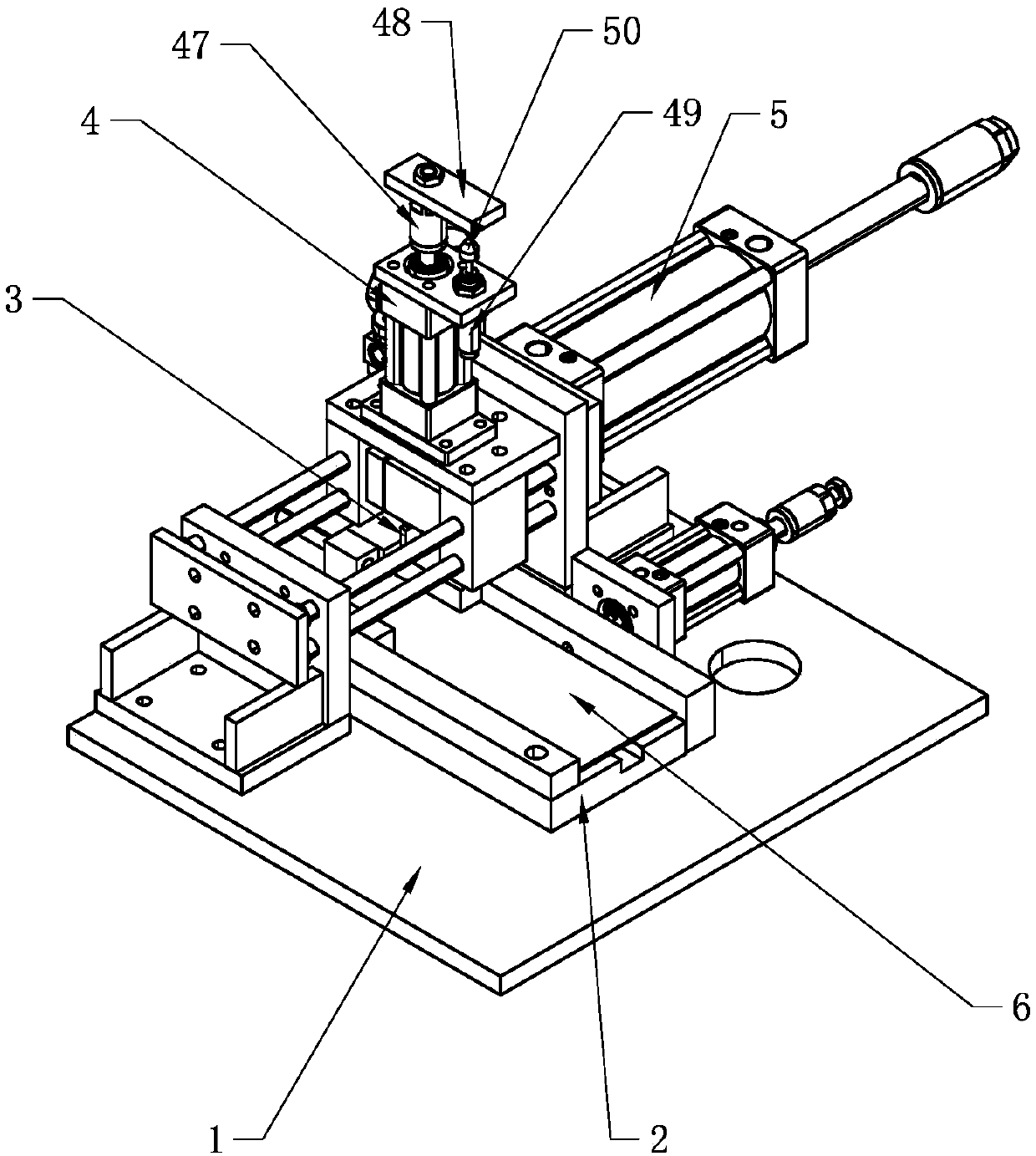

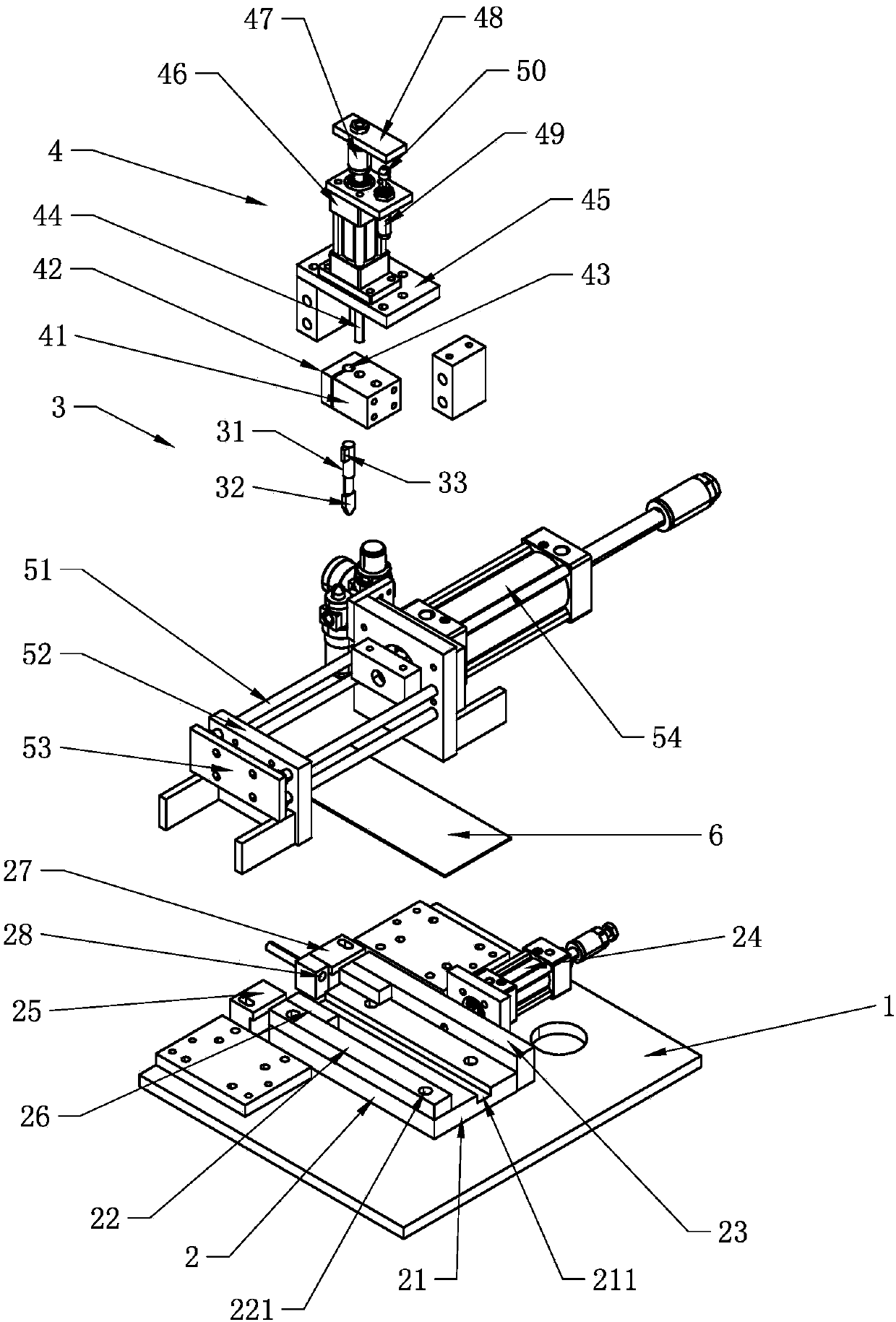

[0021] like figure 1 As shown, a lens cutting machine includes a frame 1, the frame 1 is provided with a clamp 2 for fixing the lens 6, a cutting knife 3, a translation assembly 5 for making the cutting knife 3 approach or move away from the clamp 2, and driving the cutting knife 3 to lift The lifting assembly 4, the cutting knife 3 and the translation assembly 5 are connected through the lifting assembly 4.

[0022] The translation component 5 moves the cutting knife 3 linearly to cut the lens 6 , and the lifting component 4 makes the cutting knife 3 approach and move away from the lens 6 from the vertical direction, so as to avoid repeated cutting of the lens 6 .

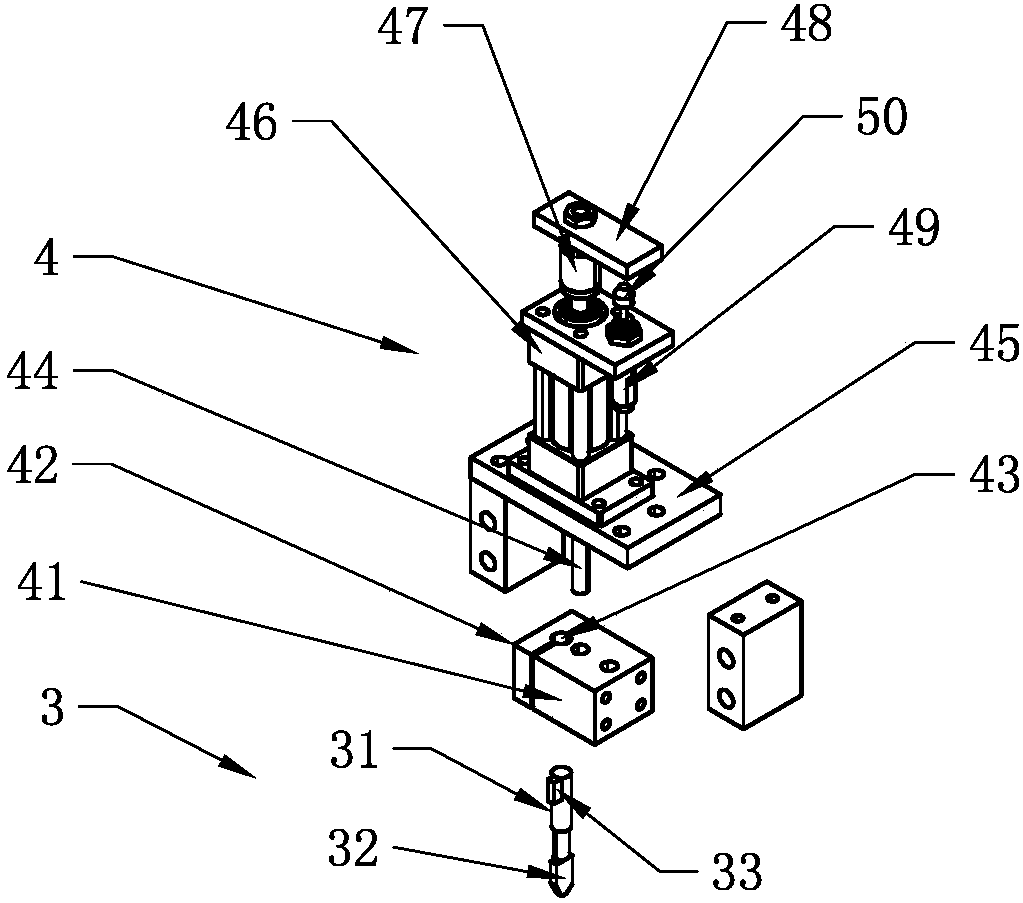

[0023] like figure 2 , image 3 As shown, the cutting knife 3 includes a blade 32 for cutting the lens 6 and a handle 31 connecting the blade 32 , the blade 32 is a common setting, and the handle 31 is provided with a first protrusion 33 that limits the rotation of the handle 31 . The first protrusion 33 can f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com