Peeling device

A technology of peeling device and servo drive device, which is applied in the directions of packaging, transportation and packaging, and unsealing of objects, can solve the problem of inability to peel off the film material, and achieve the effect of convenient adsorption operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

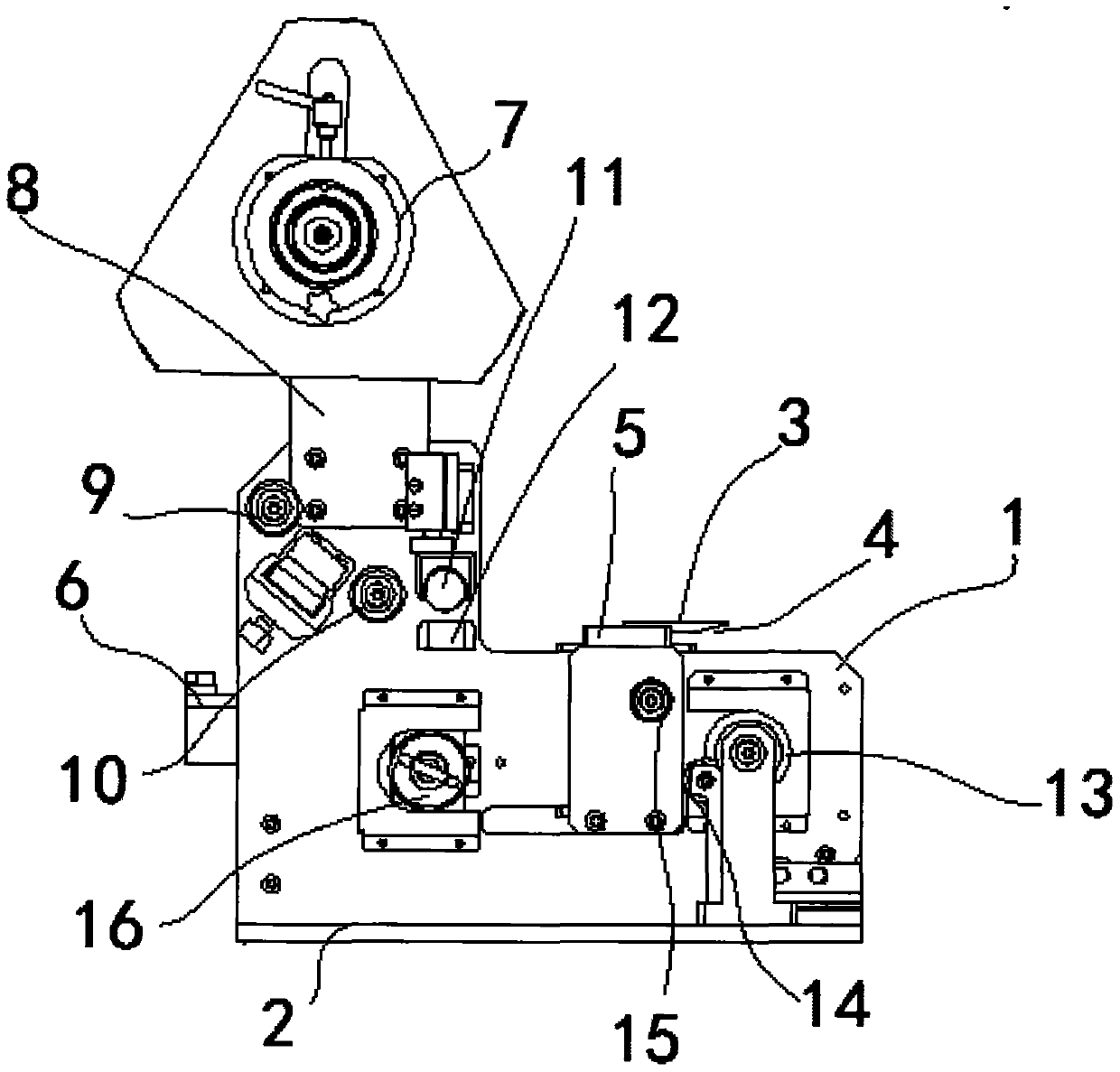

[0012] see figure 1 , a peeling device, including a movable film stripping plate 3 and a film roll retracting mechanism that cooperates with the film stripping plate to peel the film, the film stripping plate is installed on a movable horizontal bearing plate 5, The horizontal bearing plate is connected with a servo drive device 6, the servo drive device is installed on a support plate 1, the support plate is fixedly installed on a support platform 2, and the film roll retracting mechanism is installed on the support plate 1 on.

[0013] In terms of specific implementation, the peeling end of the peeling plate has an inclined surface 4 facing downwards to the inside.

[0014] Wherein, the film roll retracting mechanism includes an unwinding roller 7, a first guide roller 9, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com