Solvent-free companding and forming mold for porous propellant and companding process

A forming mold, solvent-free technology, applied in the direction of presses, manufacturing tools, offensive equipment, etc., can solve difficult problems and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

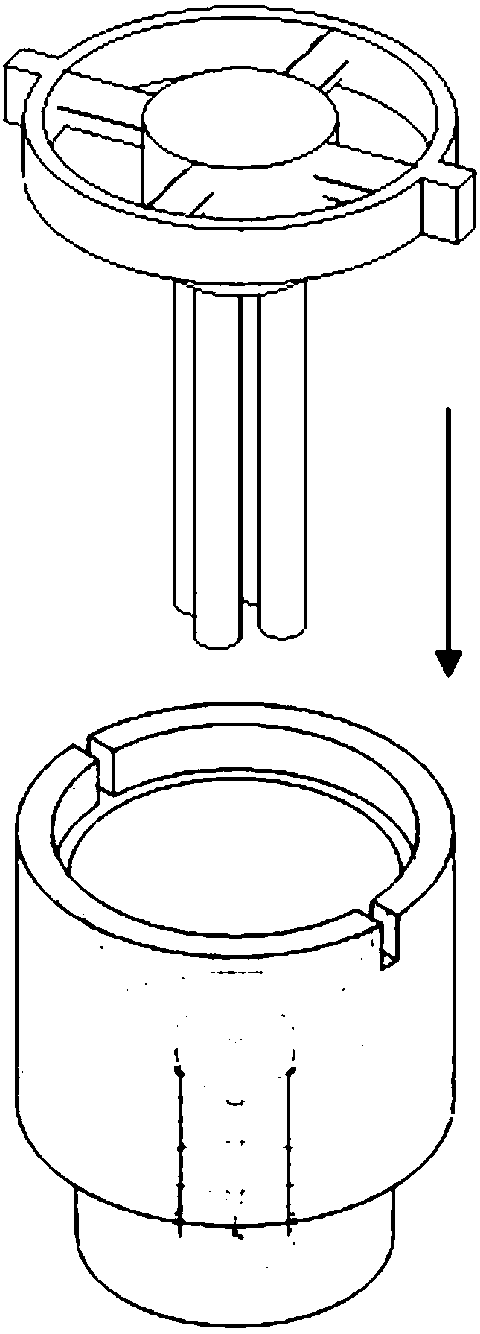

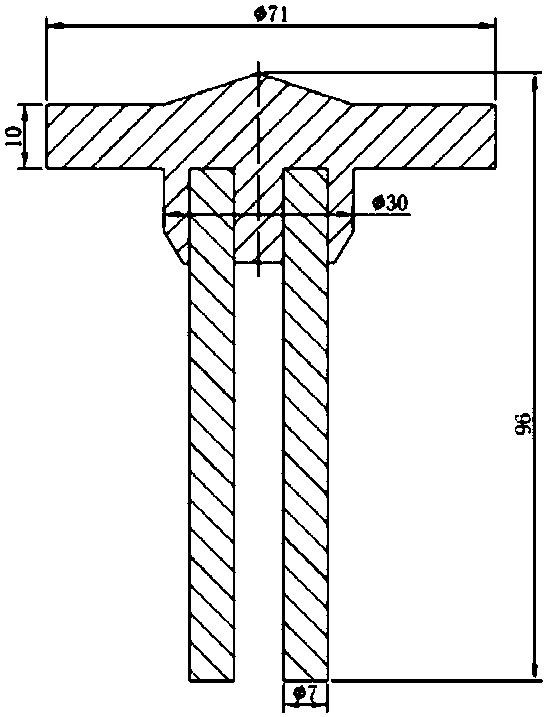

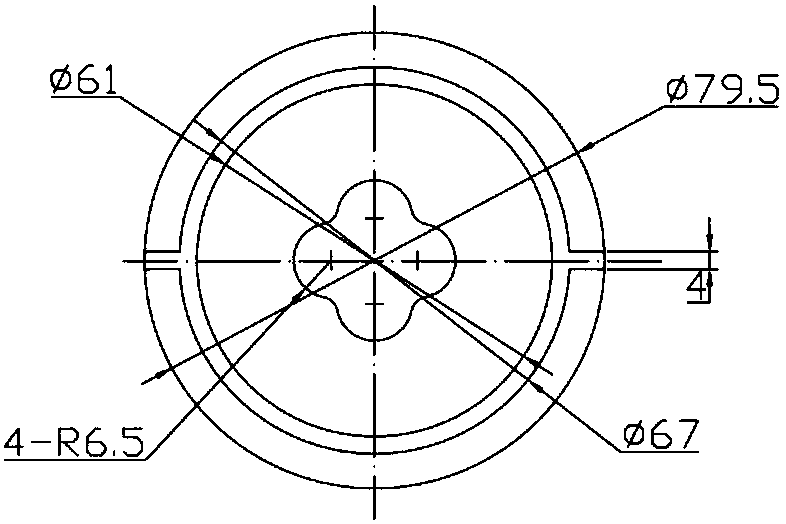

Image

Examples

Embodiment 1

[0018] Put the special soft material for pre-pressing and stretching that has been insulated at 80℃~90℃ into the mold at 85℃~95℃, hold the pressure at 3~5MPa for 8~15min, pressurize to 10MPa~12MPa to press out the soft material, and keep the drug delivery speed stable The equilibrium pressure of the medicine is 8~11MPa; after the pre-compression stretching, keep the mold temperature at 90℃~95℃, pressurize the modified double-base propellant at 80℃~85℃ at 3MPa for 10min, pressurize to 10MPa~12MPa, press Stretching. The equilibrium pressure of the drug discharge is 10.5MPa, and the pressure in the discharge process is stable, which meets the safety requirements. The surface of the drug column is smooth, and the internal structure is dense through X-ray detection, which meets the requirements.

Embodiment 2

[0020] Put the special soft material for pre-pressing and stretching that has been insulated at 80℃~90℃ into the mold at 85℃~95℃, hold the pressure at 3~5MPa for 8~15min, pressurize to 10MPa~12MPa to press out the soft material, and keep the drug delivery speed stable The equilibrium pressure of the medicine is 8-11MPa; after the pre-compression stretching, keep the mold temperature at 90°C-95°C, keep the modified double-base propellant at 80°C-85°C at 3MPa for 10min, and pressurize to 10MPa-12MPa Stretching. The equilibrium pressure of the drug discharge is 11MPa, and the pressure in the discharge process is stable, which meets the safety requirements. The surface of the product column is smooth, and the internal structure is dense through X-ray detection, which meets the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com