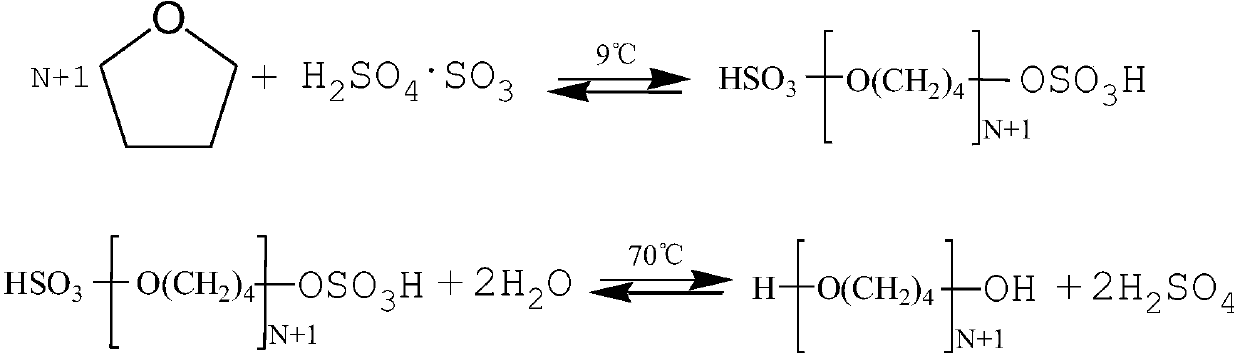

Polytetramethylene ether glycol (PTMEG) depolymerization process

A process and reactor technology, applied in the direction of organic chemistry, etc., can solve the problems of unstable depolymerization discharge, high depolymerization cost, reboiler cleaning, frequent switching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

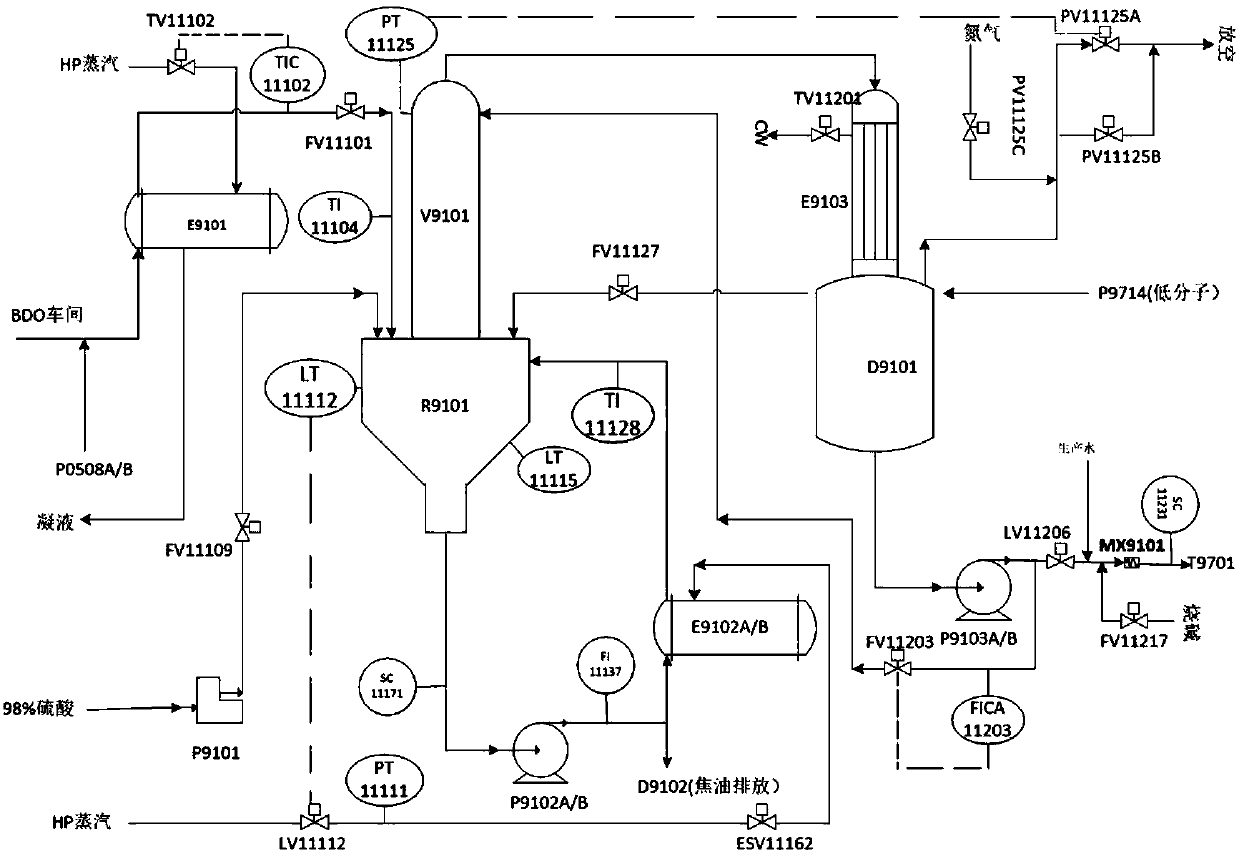

[0023] The present embodiment provides a kind of PTMEG depolymerization technique, comprises the steps:

[0024] S1. Confirm that the reactor R9101 has been cleaned and emptied, and add steam condensate to the reactor R9101 until the liquid level LT11115 reaches 10% of the tank volume;

[0025] S2. Confirm that the valve between the booster pump P0508B and the reactor R9101 is open, and the electric heat tracing on all pipelines is normally put into use;

[0026] S3. The main control adjusts the steam regulating valve TV11102 of the preheater E9101, controls the temperature of the preheater to 155°C, starts the booster pump P0508B, adjusts the pressure to 6.0bar(G), and preheats the PTMEG defective product in the preheater After reaching 155°C, send it into the reactor R9101;

[0027] S4, when the liquid level in the reactor R9101 reaches 30% of the tank volume, start the circulation pump P9102, and return the PTMEG defective product in the reactor R9101 through the reboiler ...

Embodiment 2

[0034] The present embodiment provides a kind of PTMEG depolymerization technique, comprises the steps:

[0035] S1. Confirm that the reactor R9101 has been cleaned and emptied, and add steam condensate to the reactor R9101 until the liquid level LT11115 reaches 12% of the tank volume;

[0036] S2. Confirm that the valve between the booster pump P0508B and the reactor R9101 is open, and the electric heat tracing on all pipelines is normally put into use;

[0037] S3. The main control adjusts the steam regulating valve TV11102 of the preheater E9101, controls the temperature of the preheater to 150°C, starts the booster pump P0508B, adjusts the pressure to 6.0bar(G), and preheats the PTMEG defective product in the preheater After reaching 150°C, it is sent to the reactor R9101;

[0038] S4, when the liquid level in the reactor R9101 reaches 40% of the tank volume, start the circulation pump P9102, and reflux the PTMEG defective product in the reactor R9101 after the reboiler E...

Embodiment 3

[0045] The present embodiment provides a kind of PTMEG depolymerization technique, comprises the steps:

[0046] S1. Confirm that the reactor R9101 has been cleaned and emptied, and add desalted water to the reactor R9101 until the liquid level LT11115 reaches 10% of the tank volume;

[0047] S2. Confirm that the valve between the booster pump P0508B and the reactor R9101 is open, and the electric heat tracing on all pipelines is normally put into use;

[0048] S3. The main control adjusts the steam regulating valve TV11102 of the preheater E9101, controls the temperature of the preheater to 170°C, starts the booster pump P0508B, adjusts the pressure to 6.0bar(G), and preheats the PTMEG defective product in the preheater After reaching 170°C, it is sent to the reactor R9101;

[0049] S4, when the liquid level in the reactor R9101 reaches 35% of the tank volume, start the circulation pump P9102, and return the defective PTMEG in the reactor R9101 to the reboiler E9102B, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com