Dry quenching furnace inclined air flue partition wall building dividing device and construction method

A CDQ coke oven and indexing device technology, which is applied in coke oven bricklaying operations, coke ovens, petroleum industry, etc., can solve problems such as abnormal installation, and achieve the effects of improving installation accuracy, improving utilization rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

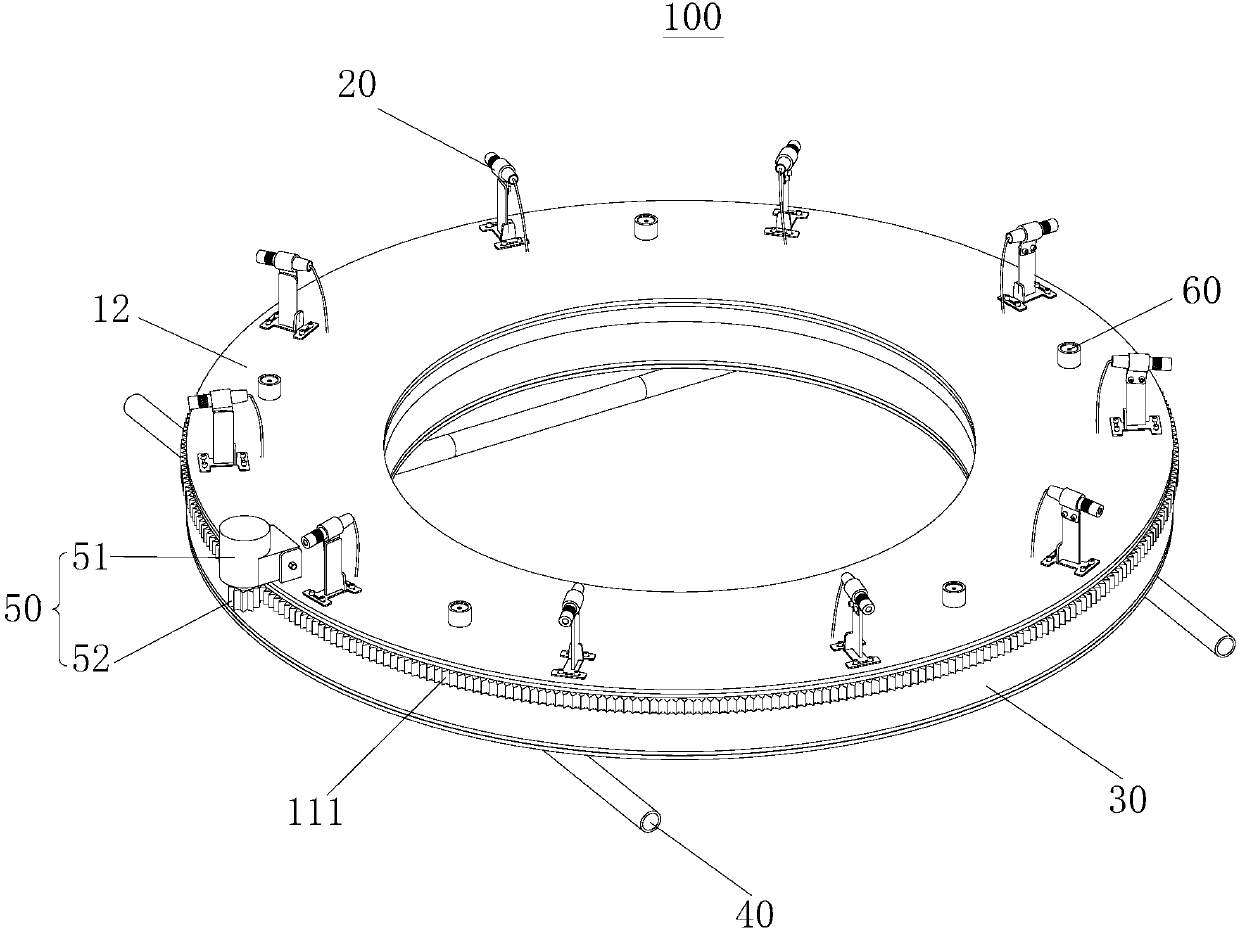

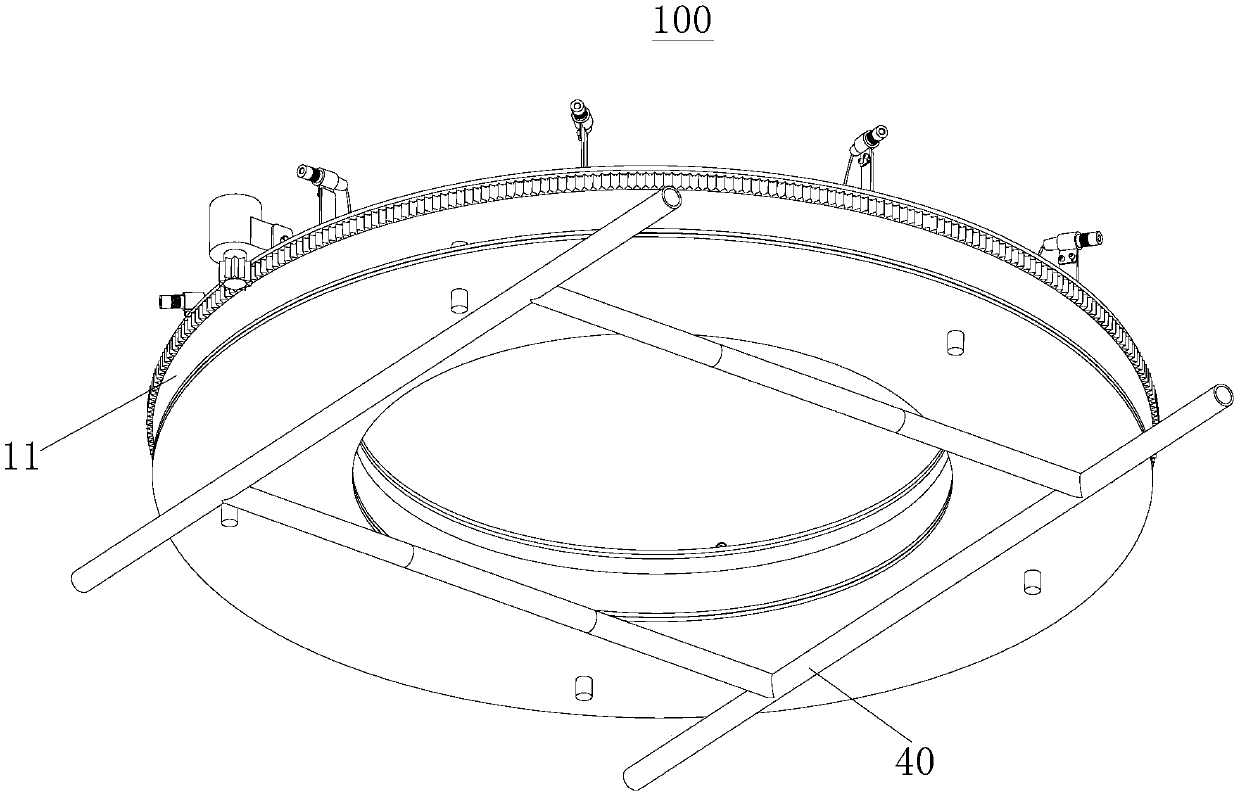

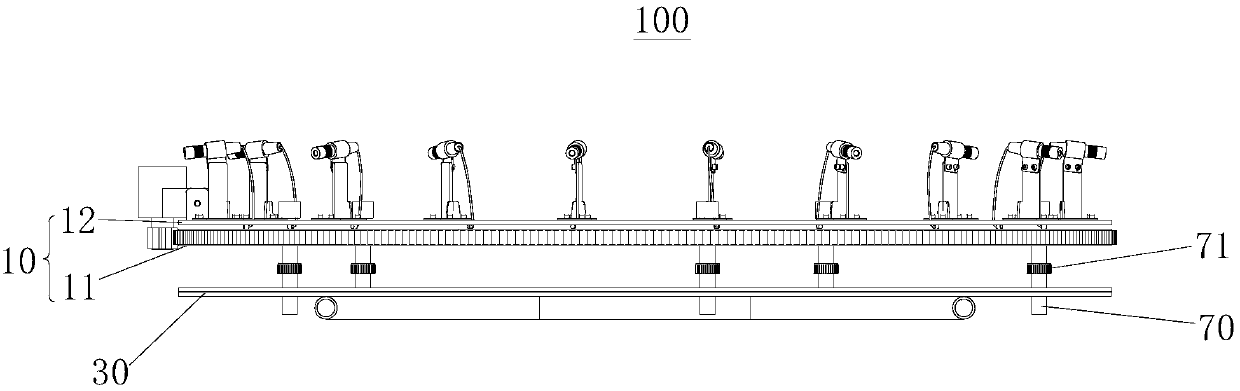

[0031] Such as Figure 1-3 As shown, it is an indexing device 100 for masonry building indexing device 100 of a coke oven slant duct partition wall according to a preferred embodiment of the present invention, which includes a spin platform 10, and the spin platform 10 includes a coaxial base 11 and a rotary platform 12, which rotate The platform 12 is rotatably mounted on the top of the base 11, the rotary platform 12 is equipped with a driving device 50, and the driving device 50 drives the rotary platform 12 to rotate relative to the base 11, and the circumferential direction of the rotary platform 12 is uniformly equipped with several line markers 20.

[0032] For further optimization, in this embodiment, in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com