Diaphragm coupling

A diaphragm coupling and coupling technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of inconvenient installation and complicated processing of couplings, and achieve convenient assembly and disassembly, tolerances Low demand, the effect of increasing the torque range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

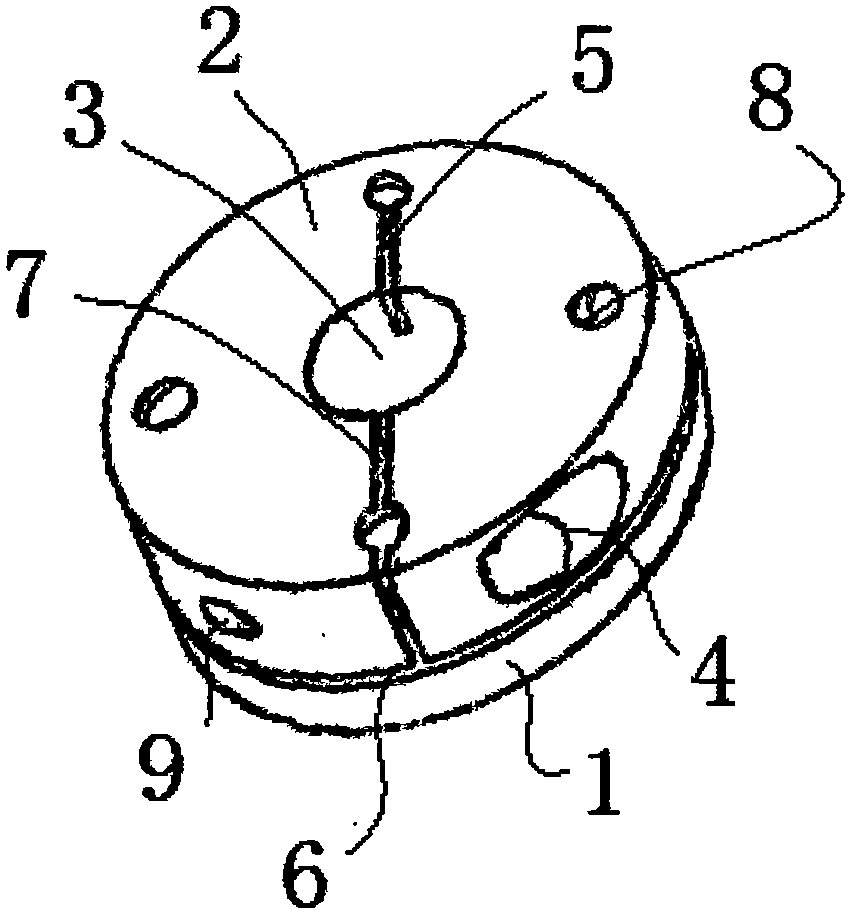

[0012] See figure 1 , a diaphragm coupling, including a coupling body 1 and a connecting body 2, a radial slit 6 is arranged between the coupling body and the connecting body, and the connecting body is outward from the center of the shaft hole 3 A first axial slit 7 and a second axial slit 5 are provided, the first axial slit and the second axial slit are on a straight line, and the connecting body and the axial end surface of the coupling body Four diaphragm fixing bolt holes 8 are evenly arranged in a cross shape, two of which are located on the centerlines of the first axial slit and the second axial slit, and the first axial slit 7 Leading to the outer circular surface of the connecting body 2 and communicating with the radial slit 6, the outer end of the second axial slit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com