Cutter with novel port

An interface and tool technology, applied in the field of tools with new interfaces, can solve the problems of many layers that cannot be superimposed, poor dynamic balance, cutting vibration, etc., to simplify dynamic balance calibration, reduce maintenance costs, and prevent wear and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

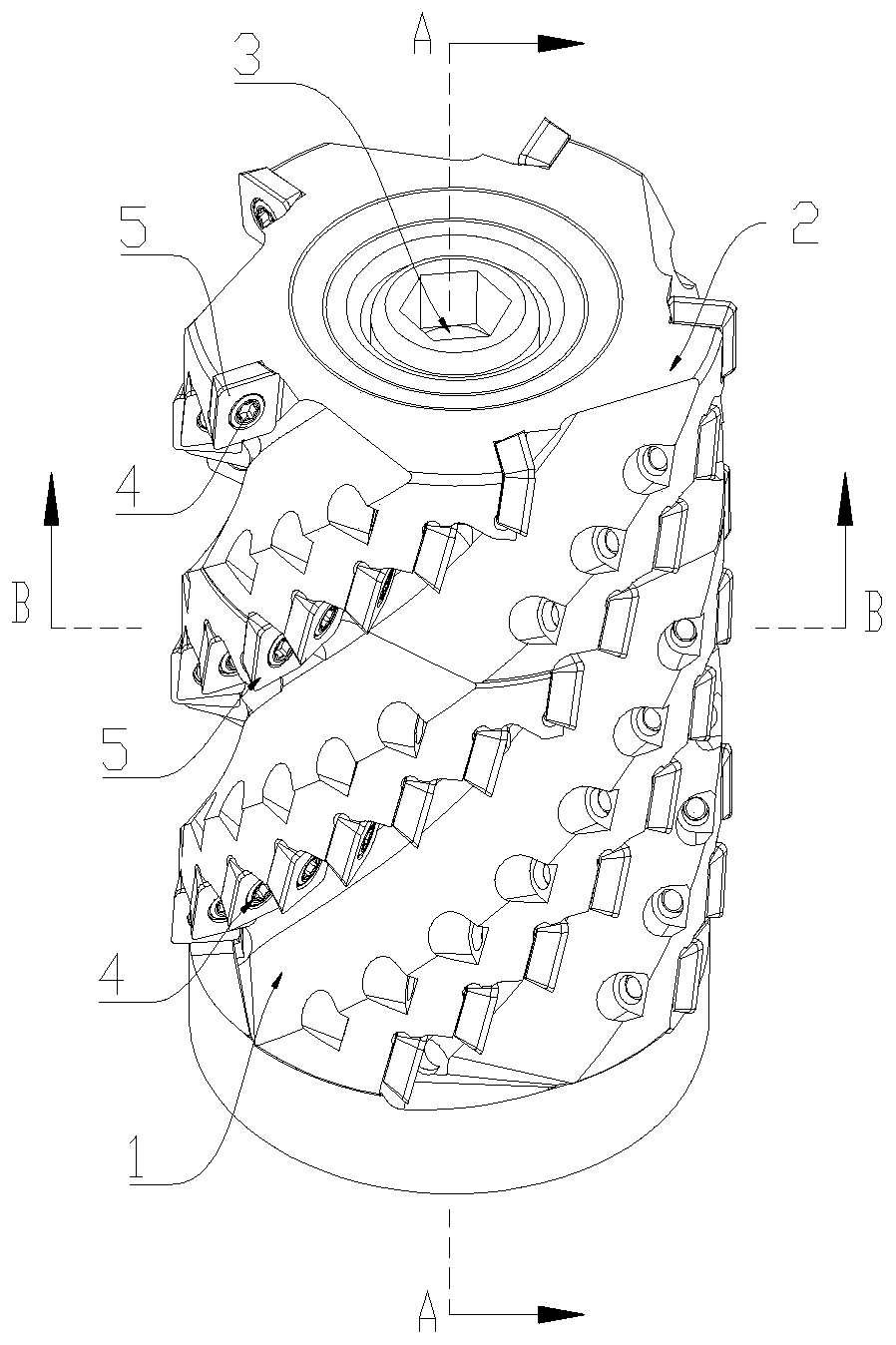

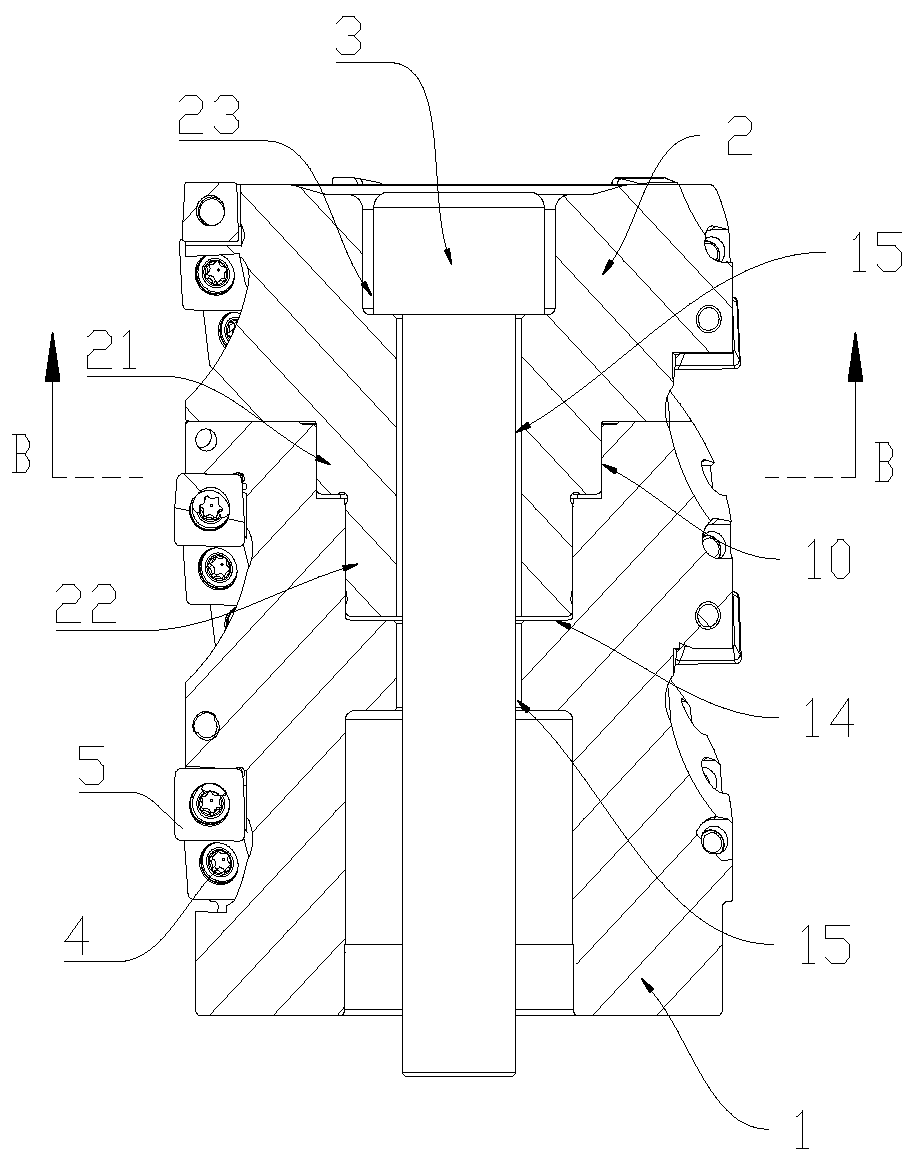

[0033] Figure 1 to Figure 7 A tool with a novel interface according to an embodiment of the invention is schematically shown. As shown in the figure, the device includes a cutter body 1 , a cutter head 2 , a bolt 3 , a plurality of blades 5 and a plurality of screws 4 . Wherein, a plurality of blades 5 are fixed on the side of the cutter head 2 or the cutter body 1 by screws 4 . The cutter body 1 is arranged opposite to the cutter head 2 , and the central axes of the cutter body 1 and the cutter head 2 are both provided with bolt through holes 15 . The top end surface of the cutter head 2 is provided with a screw counterbore 23 . The diameter of the screw counterbore 23 is larger than the diameter of the bolt through hole 15 , and the screw counterbore 23 and the bolt through hole 15 are arranged concentrically.

[0034] Such as figure 2 and Figure 4 As shown, the cutter body 1 is provided with a double counterbore structure, and the double counterbore structure includ...

Embodiment 2

[0045] The cutter with novel interface in this embodiment differs from Embodiment 1 in the following points:

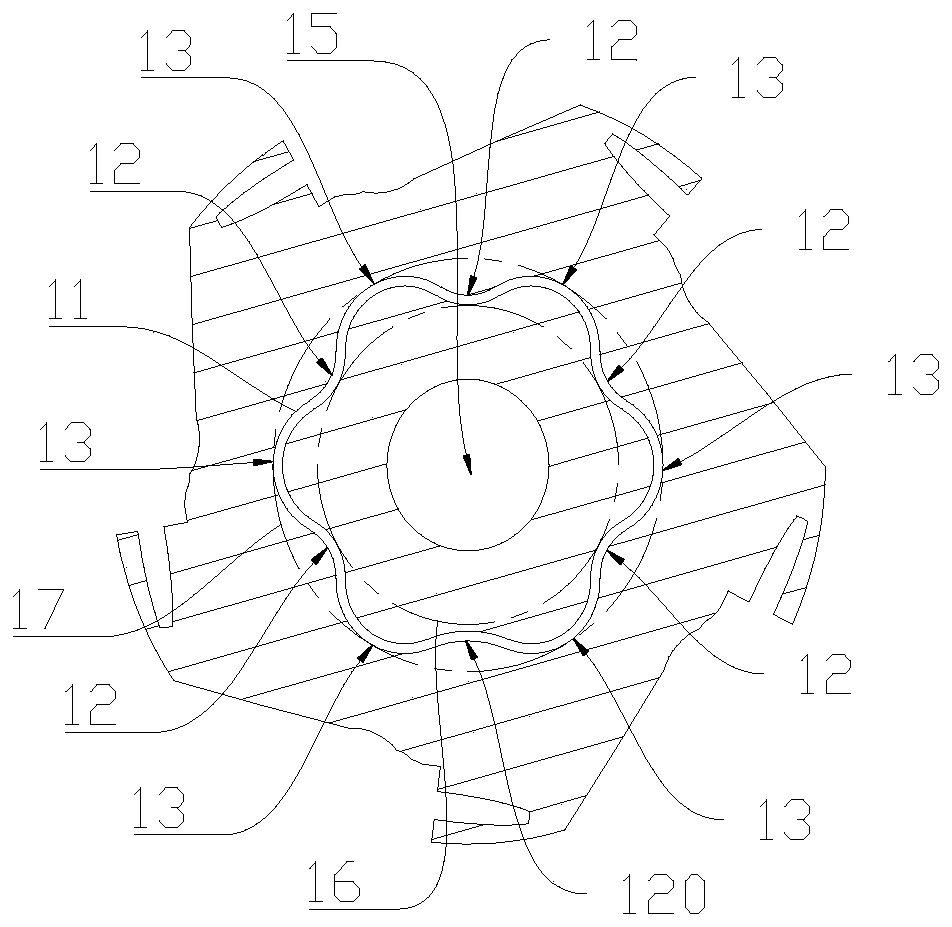

[0046] The closed curve 11 obtained by the axial projection of the torque-driven boss 21 and the torque-driven counterbore 10 from the bottom of the cutter body 1 is a six-petal quincunx shape, such as Figure 7 (f) shown. The multi-segment arcs forming the closed curve 11 include 6 convex arcs 13 with equal radii and lengths, and 6 concave arcs 12 with equal lengths. The 6 concave arcs 12 correspond to the inscribed circle 16 tangent, the 6 convex arcs 13 are tangent to the circumscribed circle 17. The mating surfaces of the torque-driven boss 21 and the torque-driven counterbore 10 form a multi-angle symmetrical form. When cutting with a tool, the mating surfaces of the torque-driven boss 21 and the torque-driven counterbore 10 are evenly stressed, which can effectively prevent tool deformation , deflection. In addition, the radii of the six convex arcs 13 are sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com