Centrally-fuel-fed swirl pulverized coal burner and over fire air arrangement structure

A technology of layout structure and swirl burner, which is applied in the direction of burners, burners, and combustion methods for burning powder fuel, can solve the problems of poor adaptability to variable loads, high emissions, and poor adaptability to coal types, etc. Large contact area, reduction of NOx generation, and enhanced reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

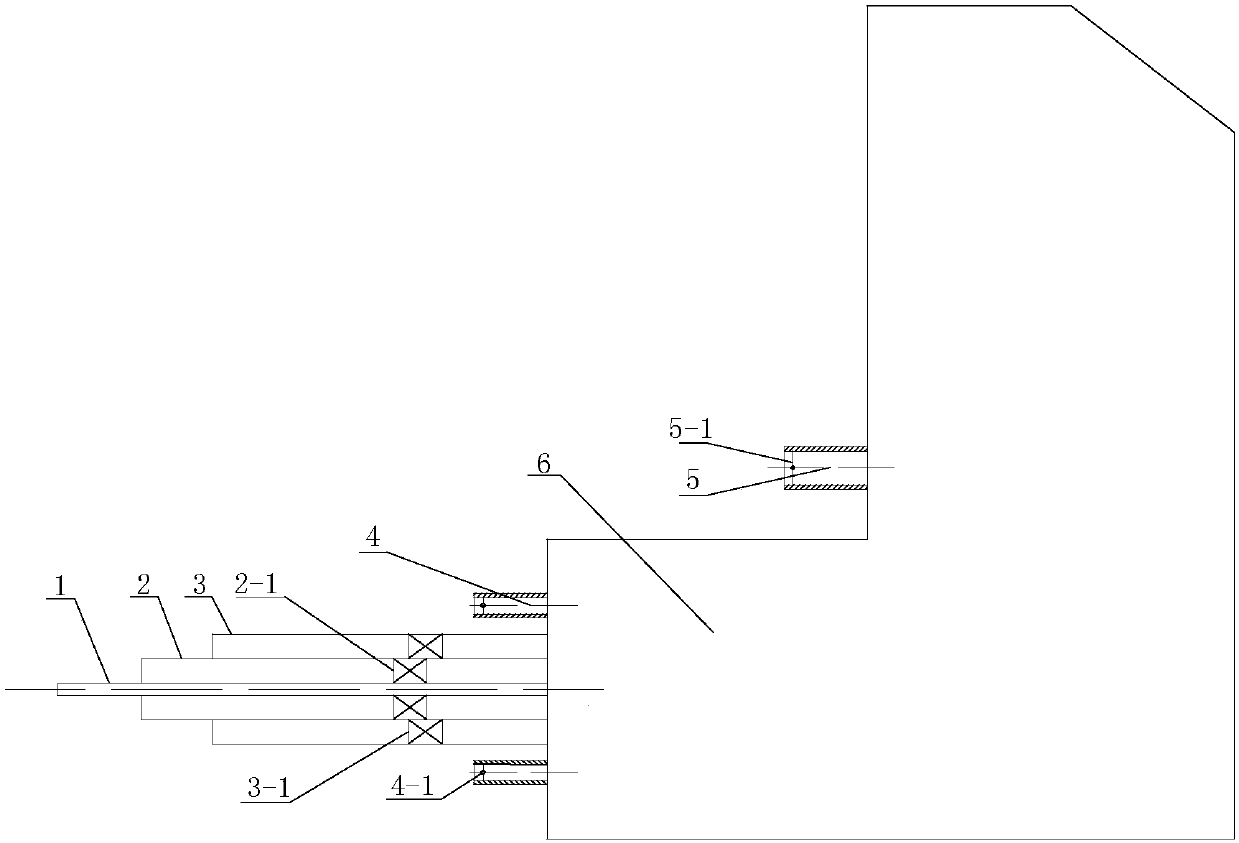

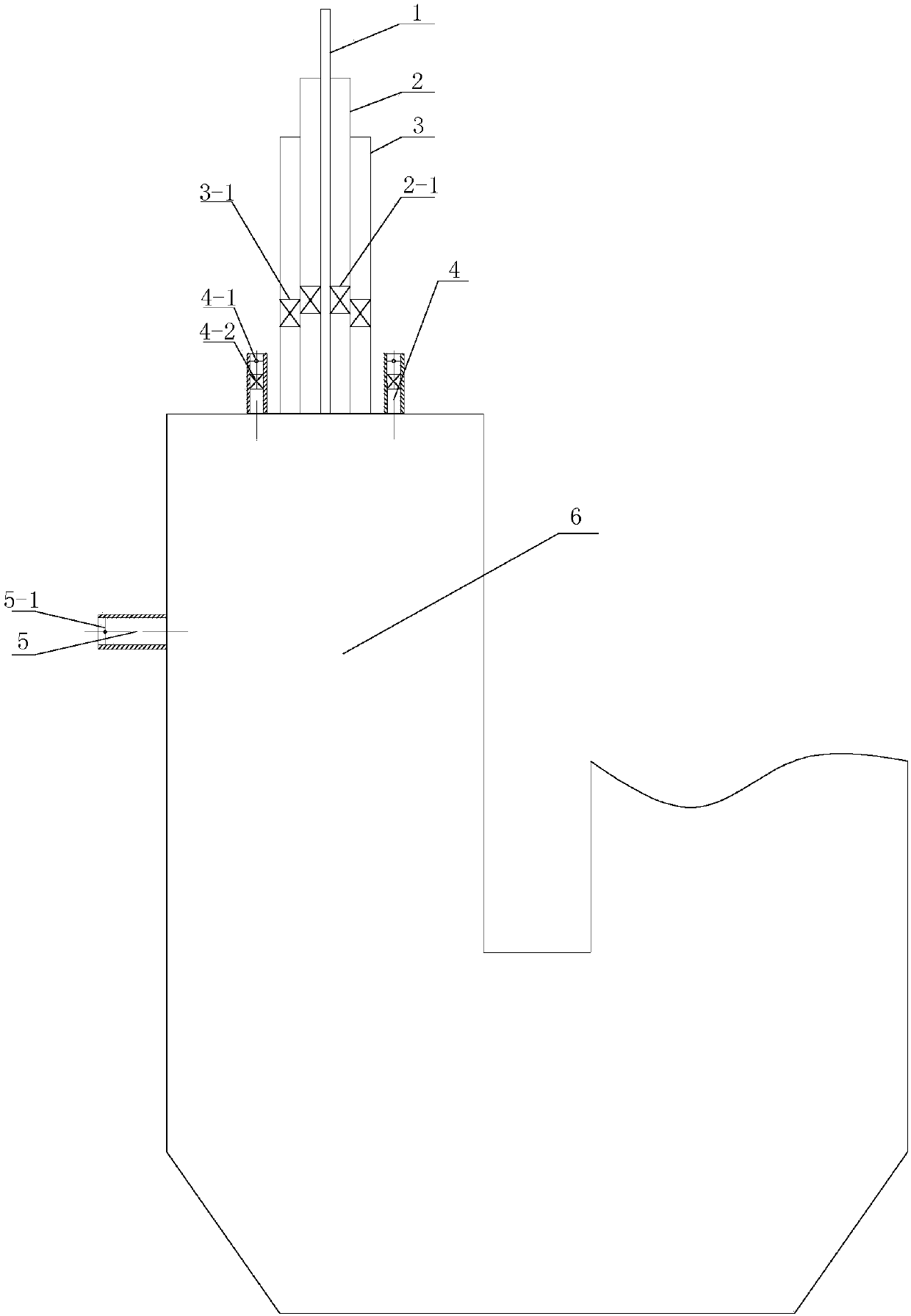

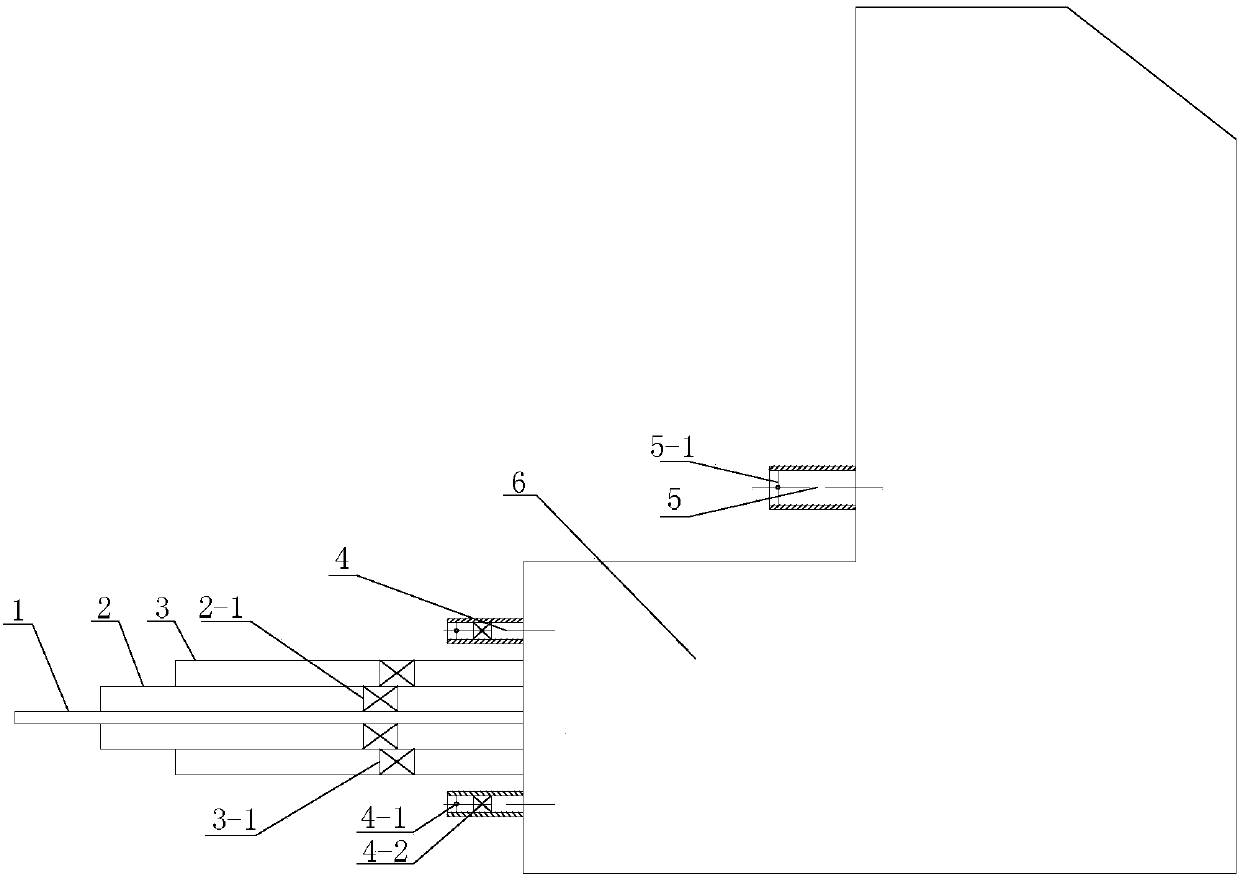

[0027] Specific implementation mode one: as Figure 1-6 As shown, the arrangement structure of the central powder feeding swirl pulverized coal burner and the overfire air in this embodiment includes a central powder feeding swirl burner, a primary overburning air nozzle group 4, and a plurality of secondary overburning air nozzles 5 , the primary overburning air regulating damper 4-1 and the secondary overburning air regulating damper 5-1; the center powder feeding swirl burner includes a primary air duct 1, an inner secondary air channel 2, an inner secondary air swirl Flow device 2-1, outer secondary air channel 3, outer secondary air cyclone 3-1; the primary air pipe 1 is set in the inner secondary air channel 2, and the inner secondary air channel 2 is set in the outer In the secondary air channel 3, the primary air duct 1, the inner secondary air channel 2 and the outer secondary air channel 3 are coaxially arranged, and the inner secondary air channel 2 is provided with...

specific Embodiment approach 2

[0029] Specific implementation mode two: as Figure 1~3 As shown, the radial distance from the axis of the thin jet tube of the primary overfire air nozzle 4 in this embodiment to the axis of the central powder feeding swirl burner is 300-1500mm. With such a design, the air for pulverized coal combustion is mixed in step by step to strengthen the staged combustion of air. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: as Figure 1~3 As shown, the radial distance from the axis of the secondary overburning air nozzle 5 to the axis of the primary overburning air nozzle 4 in this embodiment ranges from 1000 mm to 5000 mm. With such a design, the air for pulverized coal combustion is mixed in step by step, and the staged combustion of air is strengthened on the premise of improving the adaptability of coal types. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial distance | aaaaa | aaaaa |

| Radial distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap