Heat exchange pipe and heat exchanger comprising same

A technology of heat exchange tubes and tube bodies, which is applied in the field of heat exchange tubes, can solve problems such as the decrease in heat exchange efficiency of heat exchangers, and achieve the effects of reducing thermal resistance, reducing heat exchange efficiency, and reducing heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

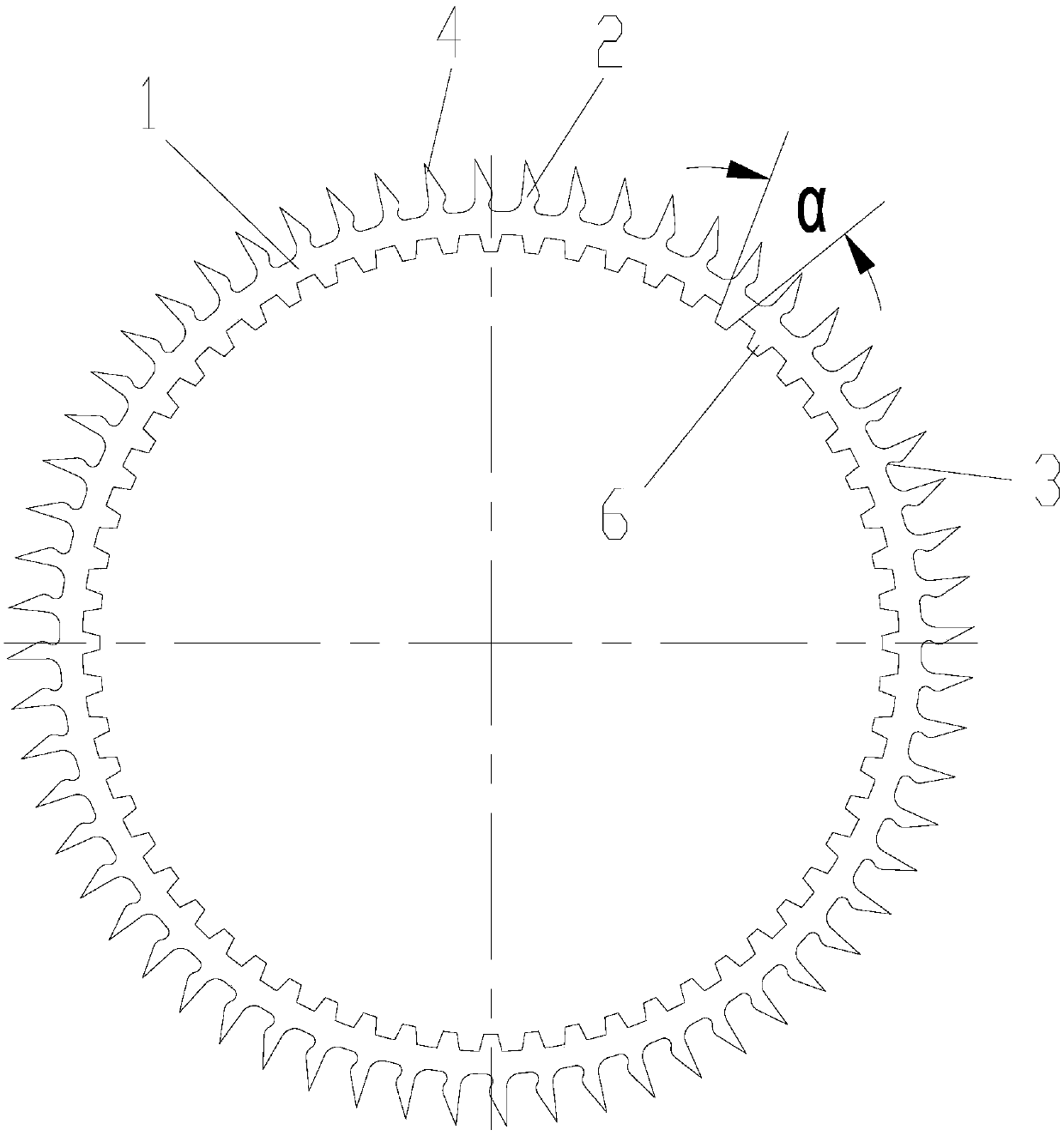

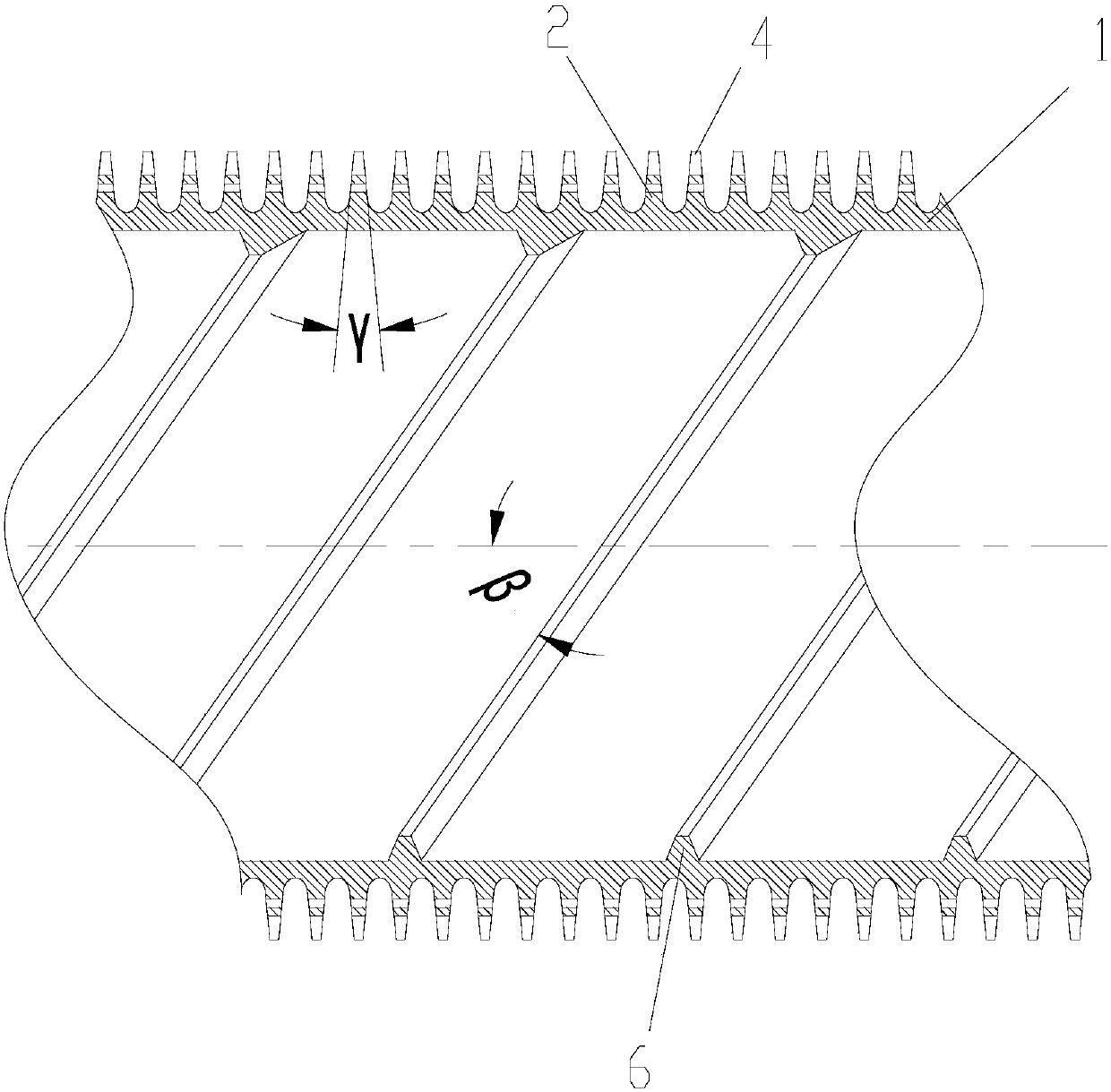

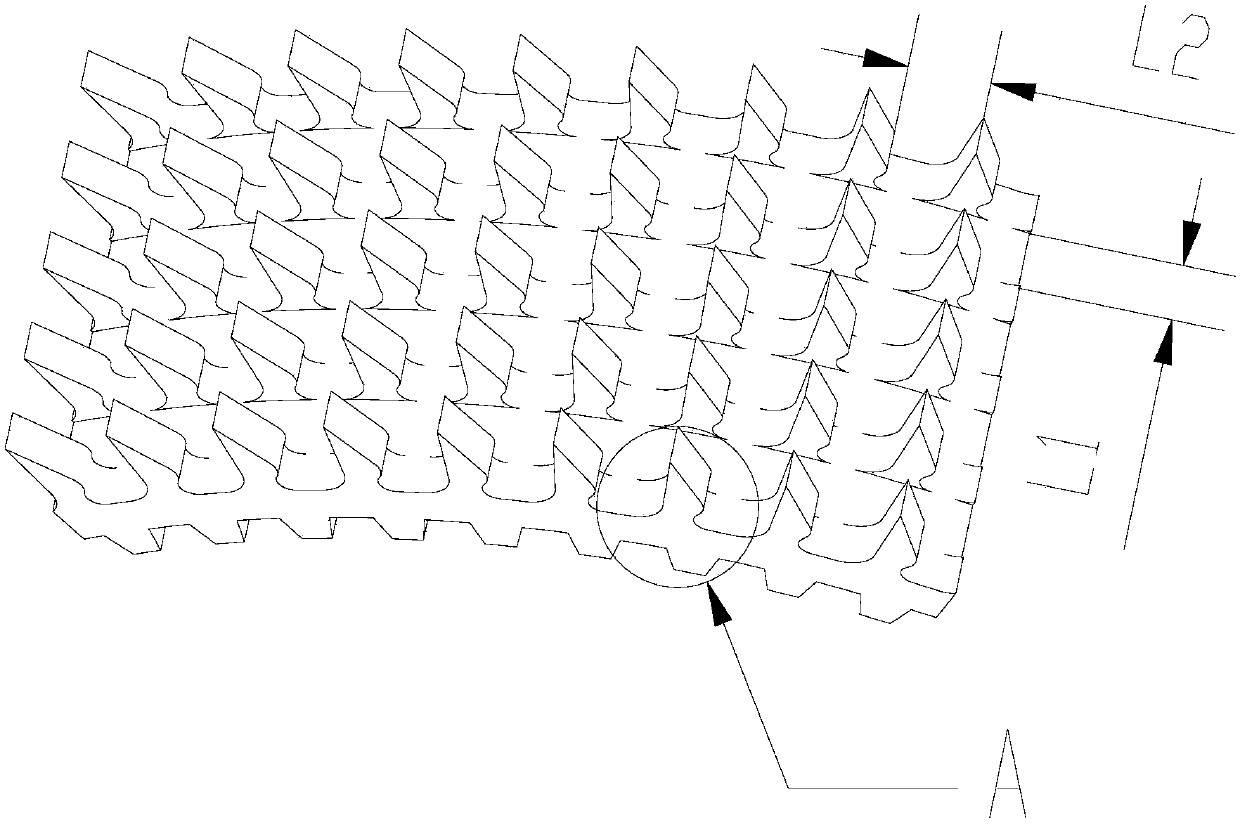

[0039] Based on the problems mentioned in the background art section, the first aspect of the present invention provides a heat exchange tube to overcome, for example, the problem of the heat exchange efficiency of the heat exchanger after the air conditioning unit is switched.

[0040] Before describing the heat exchange tube of the present invention in detail, first briefly explain the heat exchange principle of the heat exchange tube. The heat exchanger in the air conditioner is divided into a condenser and an evaporator. Accordingly, the heat exchange process is divided into condensation heat exchange and evaporation heat exchange.

[0041] Among them, the heat transfer mechanism of condensation heat exchange is condensation heat exchange, which is divided into film condensation and bead condensation, and the condenser is generally film condensation heat exchange. During film condensation, the presence of the condensed liquid film constitutes the thermal resistance of the conde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com