Surface mine high-temperature blasting device and construction method thereof

A high temperature and mine technology, applied in the field of high temperature blasting devices in open-pit mines, can solve the problems of unfavorable on-site construction management, hurried and tense blasting construction process, and high cost of protective materials, which is beneficial to on-site construction management, improves blasting and stripping efficiency, and reduces preliminary preparations. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

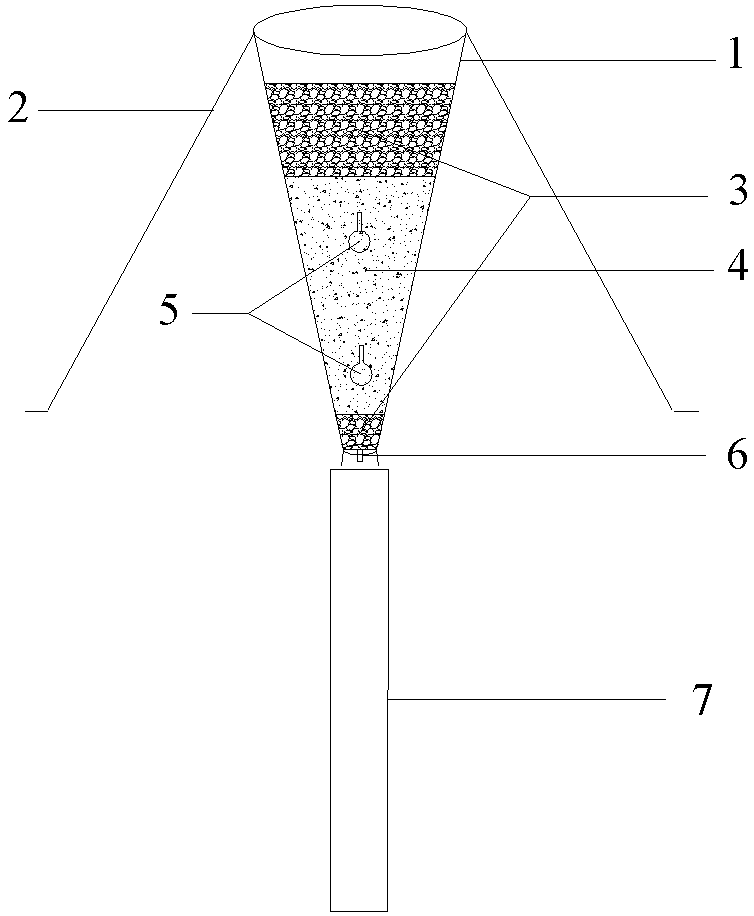

[0037] see figure 1 , the high-temperature blasting device for open-pit mines of the present invention is characterized in that it includes a container 1, a bracket 2, a blockage 3, an explosive 4, a detonating material 5, and a switch 6; wherein, the bracket 2 is used to support the container 1; the container 1 is installed on the support mechanism 2 and is located above the high-temperature blast hole 7, and the lower port of the container 1 is aligned with the high-temperature blast hole 7; the inside of the container 1 is divided from bottom to top The layer is equipped with explosives 4 and blockages 3 , and the explosives are embedded with detonating materials 5 ; the switch 6 is used for remote control to automatically load the explosives 4 , detonating materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com